Laser peening composite rolling strengthening surface modification method and device

A laser shot peening and surface modification technology, applied in the field of surface deformation strengthening, can solve problems such as poor surface quality and uneven stress distribution, and achieve the effect of large residual compressive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

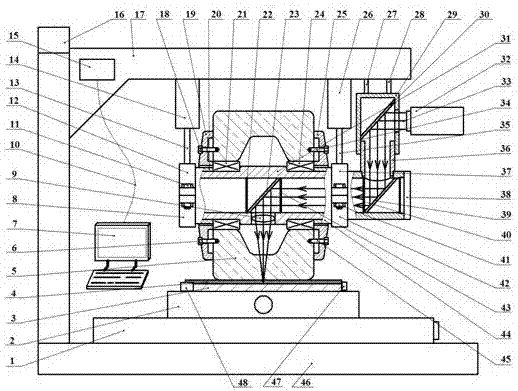

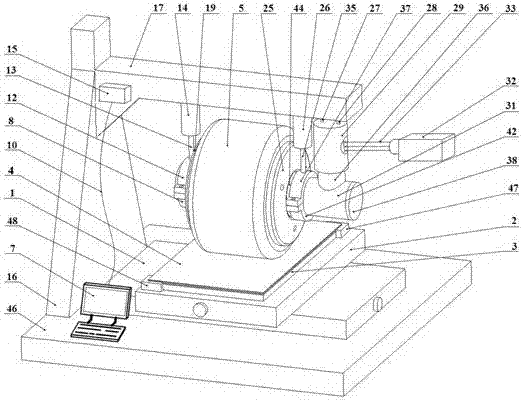

[0035] like Figure 1-4 shown.

[0036] A method for laser shot peening composite rolling strengthening surface modification, the specific steps are as follows:

[0037] 1) Grinding and polishing the surface of the workpiece 3 to be strengthened for pretreatment, and then closely attaching 50-200 μm aluminum foil 4 on the surface for later use; Figure 1-2 ;

[0038] 2) Turn on the computer 7, set the laser peening parameters, compile the program to control the X, Y mobile platforms 1, 2, and the hydraulic cylinders 14, 26 and the laser 32 work together;

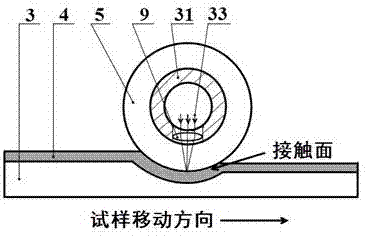

[0039] 3) By controlling the hydraulic cylinders 14 and 26, the transparent rolling wheel 5 acts on the workpiece 3 positioned on the Y-axis moving platform 2 with a preset load of 200-300 MPa, the surface of the workpiece 3 undergoes initial deformation, and the rolling wheel 5 Contact with the surface of the workpiece 3 with an arc surface, such as image 3 ;

[0040] 4) The laser 32 emits light, and performs laser sh...

Embodiment 2

[0046] like Figure 1-2 shown.

[0047] A device for laser shot peening composite rolling strengthening surface modification, including a control system and a mobile platform controlled by the control system, a hydraulic system, a rolling system, a laser 32 and an optical path system, and the rolling system is under the action of the hydraulic system Compressing produces a preset load on the surface of the workpiece and causes plastic deformation on the surface of the workpiece. The moving platform drives the workpiece to move in the X and Y directions to achieve laser shot peening and rolling strengthening in the entire strengthening area. The laser 32 generates laser light passing through The optical path system is introduced into the main shaft of the rolling system and passes through the transparent rolling wheel through the condenser lens 9 fixed on the main shaft to irradiate the surface of the workpiece to perform laser shot peening on the workpiece. like figure 1 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| laser intensity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com