Processing technology for high-bearing-capacity high-load connecting rod surface shot peening strengthening

A shot peening and processing technology, applied in metal processing equipment, manufacturing tools, used abrasive treatment devices, etc., can solve problems such as fatigue cracks, poor shot peening surface quality, connecting rod fractures, etc. Fatigue strength and reliability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

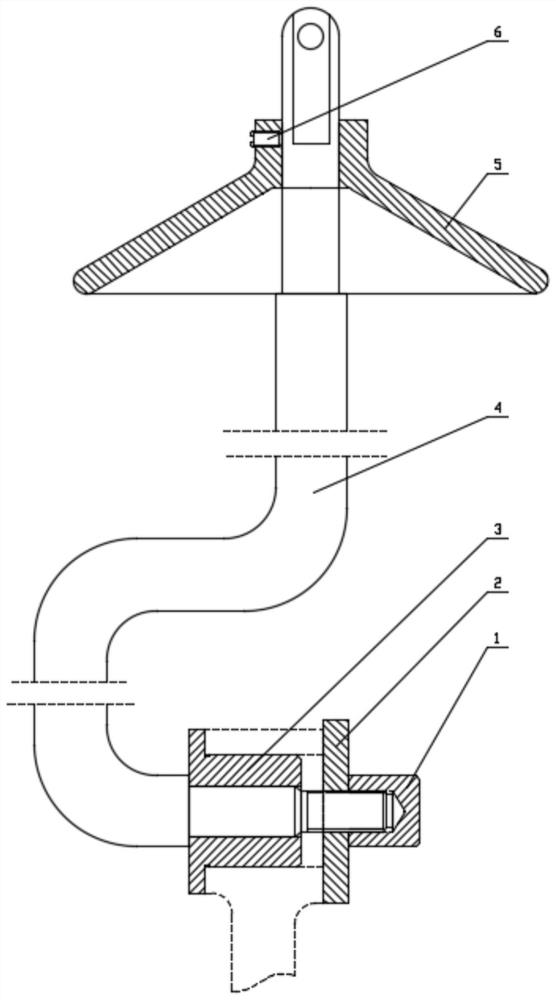

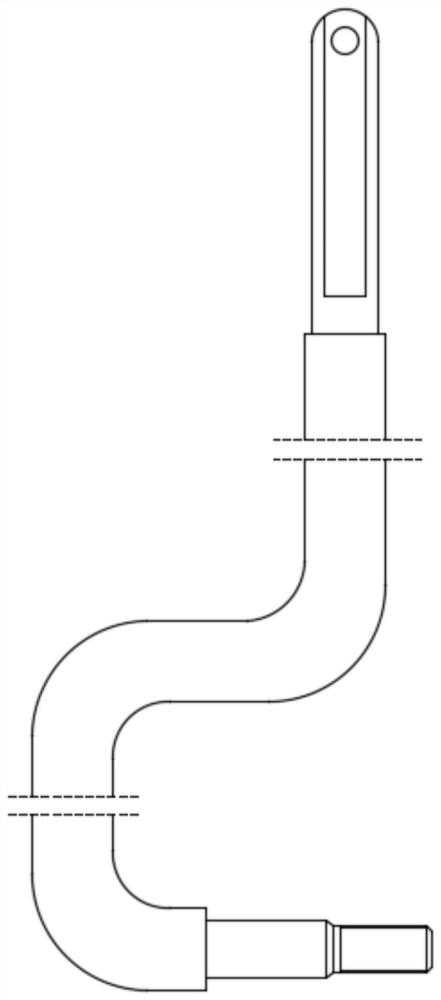

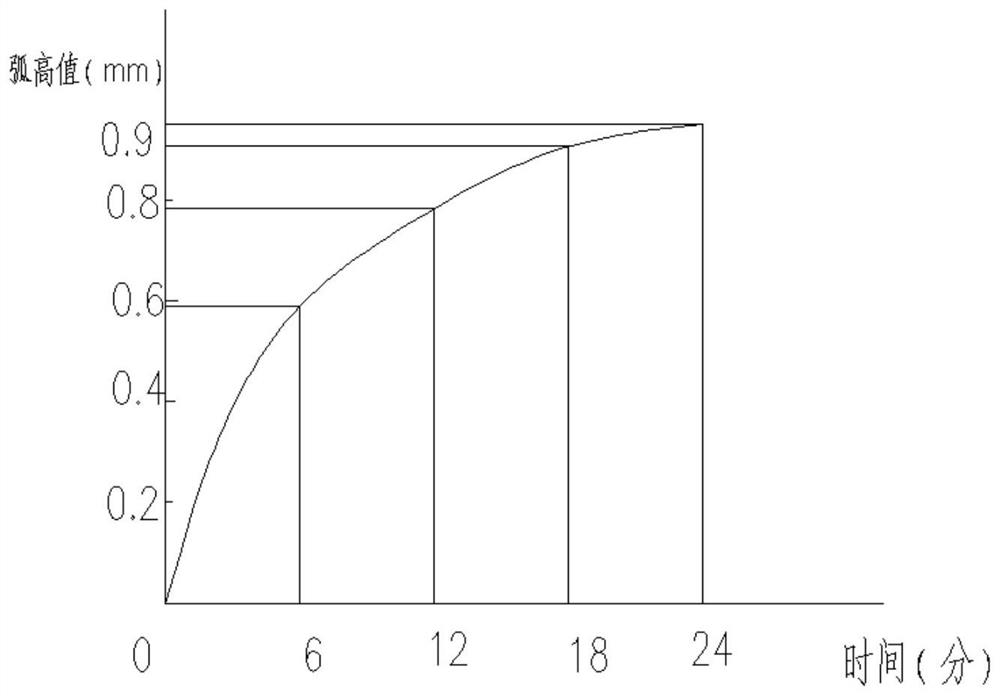

[0035] The connecting rod structure is relatively complex, the total length is about 480mm, the width of the large end is about 200mm, and the width of the small end is about 86mm. 100% shot peening surface coverage is required. The detection standard of the shot peening process is to detect the arc height value of the test piece and generate residual compressive stress to improve the fatigue strength of the connecting rod. The shot peening test piece adopts A-type ALmen, and the material of the test piece is SAE1010 cold-rolled spring steel, uniformly quenched to HRC44-50. The drawings require an arc height of 0.5-0.6mm, and at the same time, a stable residual compressive stress is formed on the surface of the shot peening, with a value of -300--600MPa.

[0036] A processing technology for surface shot peening of high-load and high-load connecting rods, comprising the following steps:

[0037] (1) Shot blasting machine for rod production line, model Q3158, choose carbon spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com