Intra-light water delivery laser shock peening method and device

A technology of laser shock strengthening and water delivery, which is applied in laser welding equipment, welding equipment, metal processing, etc., can solve the problems of turbulence in the water-constrained layer, easy formation of voids, and influence on the stability of the water-constrained layer in the processing area. Synchronization, conducive to uniform distribution, and reduce the effect of "stress hole" effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

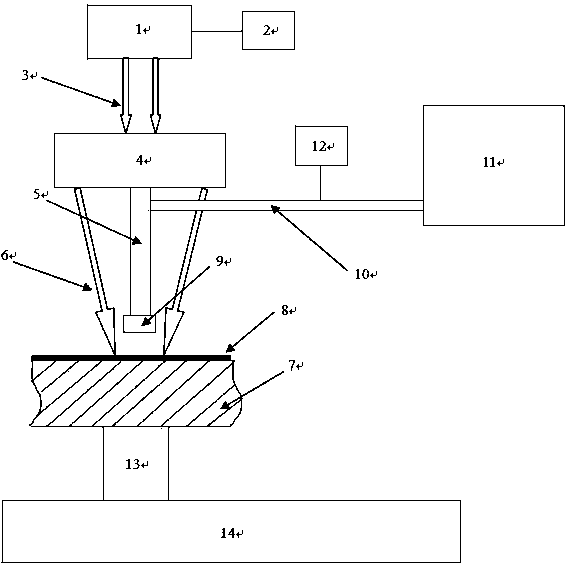

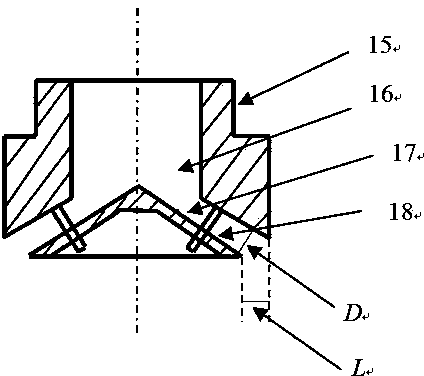

[0027] A device for laser shock strengthening of water in the light, such as figure 1 As shown, it includes: laser 1, laser control device 2, optical path converter 4, fixture 13, five-axis workbench 14, main water pipe 5, nozzle 9, water inlet pipe 10, water flow controller 12 and water tank 11; wherein the structure of nozzle 9 is Such as figure 2 As shown, it includes: connecting thread 15, water inlet 16, tapered water outlet 17, connecting rod 18.

[0028] The fixture 13 is installed on the five-axis table 14; the laser 1 is located opposite to the five-axis table 14; the laser control device 2 is connected to the laser 1 to control the output pulse energy, spot diameter and pulse width of the laser; the optical path converter 4 is located on the laser Between 1 and the five-axis workbench 14, it is used to transform the circular laser beam 3 into a hollow laser beam 6; the main water pipe 5 is installed on the optical path changer 4; the nozzle 9 is connected with the ...

Embodiment 2

[0030] The specific steps to implement the laser shock strengthening of water delivery in the light are as follows:

[0031] (1) Turn on the laser 1, set the output pulse energy of the laser 1 to 6 J, the spot diameter to 3 mm, and the pulse width to 20 ns through the laser control device 2;

[0032] (2) The circular laser beam 3 is converted into a hollow laser beam 6 by the optical path converter 2, and the hollow laser beam 6 is required to be coaxial with the main water pipe 5 and not to interfere with the main water pipe 5. The inner diameter of the hollow laser beam 6 is consistent with the nozzle The outer diameters of 9 are equal, both are 4 mm;

[0033] (3) Turn off the laser 1, coat the surface of the workpiece 7 with the absorbing layer 8 and install it on the fixture 13 of the five-axis worktable 14, and then select the nozzle outlet width D is 1mm, L is 1.2 mm, according to the formula Move the workpiece 7 through the five-axis worktable 14, so that the dista...

Embodiment 3

[0037] The shower nozzle outlet width in embodiment two DIt is set to 1.5 mm, the pressure of the water flow is set to 0.2 MPa, the apex angle of the conical surface is 170°, and other methods and steps remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com