System and method for automatic control over laser shock peening

A laser shock strengthening and automatic control technology, applied in the field of laser strengthening treatment of metal surfaces, can solve the problems of incomplete process research and technical standards, inability to reasonably control laser process parameters, and low ability of automatic production, so as to improve the resistance to foreign body damage. ability, avoid major failures, and realize the effect of digitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

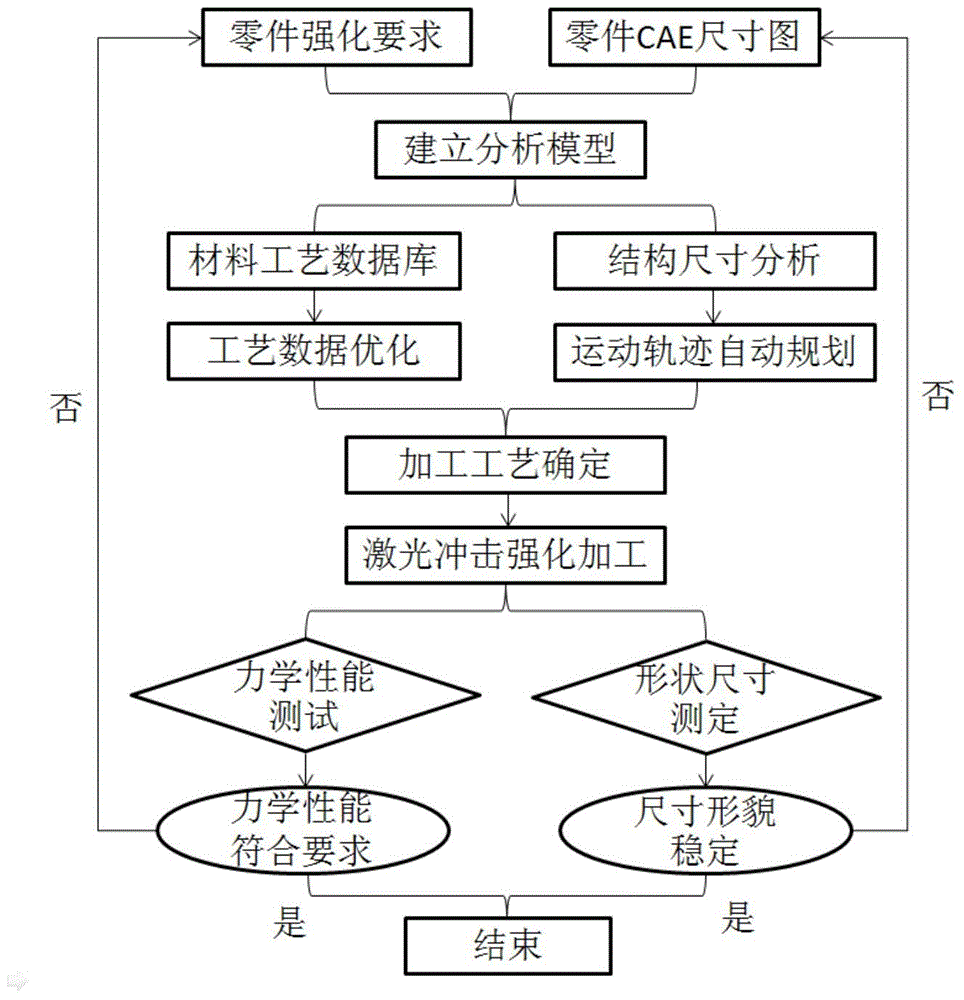

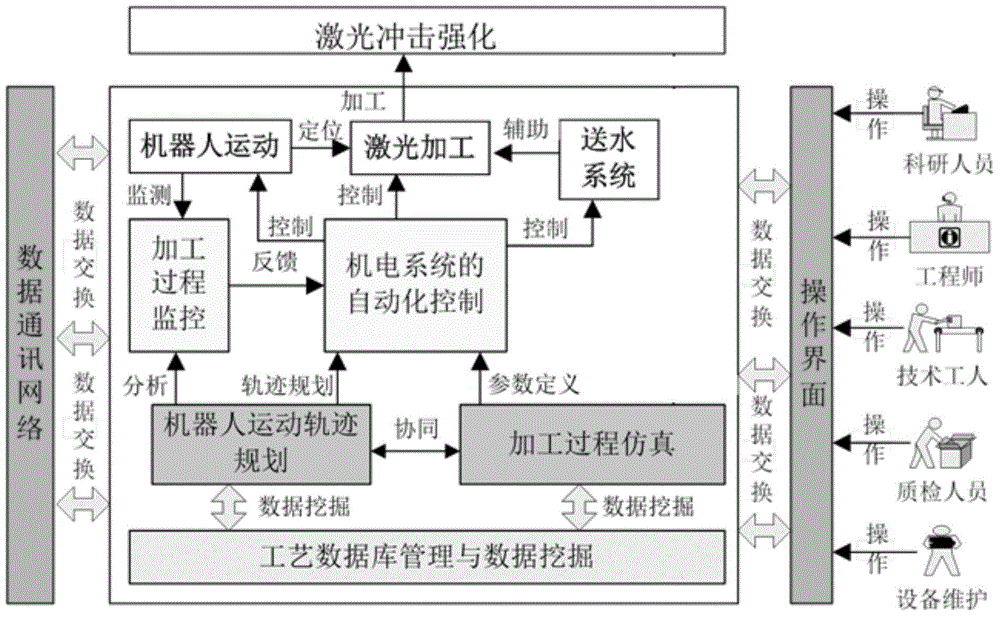

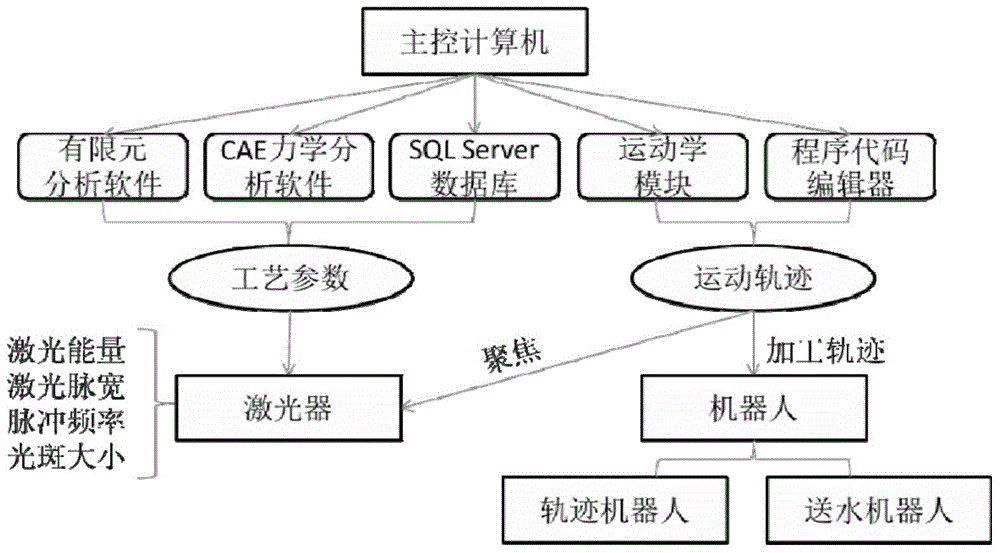

[0044] Laser shock strengthening of the overall blisk of the aero-engine to improve the fatigue performance and the ability to resist foreign object damage, such as Figure 7 As shown, firstly, the mechanical analysis software Abaqus7.0 is used to analyze the fatigue performance of the overall blade disk of the aero-engine, and the laser shock strengthening performance index, initial conditions, boundary conditions, material properties and material process parameters are input, and the distributed C / S mode SQLServer background database, build residual stress distribution model, and then import it into structural mechanics CAE analysis software, according to force analysis results and performance requirements, automatically generate laser shock wave pressure and processing trajectory on the surface of metal sheet. According to the calculated shock wave pressure, the industrial computer system automatically selects and optimizes the process parameters of the laser through the fu...

Embodiment 2

[0046] Laser shock strengthening is carried out on the anode tungsten alloy of the short-arc mercury lamp to increase its surface hardness to prolong its service life. First, import the anode tungsten alloy size drawing into the Abaqus7.0 mechanical analysis software, and then analyze the stress on the anode tungsten alloy. , set the laser shock strengthening performance index, initial conditions, boundary conditions, material properties and material process parameters, and call the SQLServer background database with distributed C / S mode to build the corresponding relationship model between surface hardness and impact times, and import it into the structure Mechanics CAE analysis software generates motion trajectory. According to force analysis results and performance requirements, CAE software automatically plans the laser shock wave pressure and processing motion trajectory on the surface of the metal sheet. According to the calculated shock wave pressure, the industrial comp...

Embodiment 3

[0048]Laser shock strengthening is carried out on the helicopter titanium-aluminum alloy hub to increase its surface hardness to prolong its service life. First, import the anode tungsten alloy dimension drawing into the Abaqus7.0 mechanical analysis software, and then carry out force testing on this type of cast titanium-aluminum alloy Analyze the situation, set the laser shock strengthening performance index, initial conditions, boundary conditions, material properties and material process parameters, including the phase transition point of 1250 ℃, yield strength of 520MPa, specific strength of 1020K, crystal structure of body-centered cubic and body-centered tetragonal , and adjust the SQLServer background database to build a model of the relationship between surface residual stress and impact times, import it into structural mechanics CAE analysis software, and generate motion trajectories. According to the force analysis results and performance requirements, the CAE softwar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition point | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com