Laser Shock Strengthening Method for Tenon and Groove Parts of Superalloy Small Size Turbine Disc

A technology of laser shock strengthening and high-temperature alloys, which is applied in laser welding equipment, metal processing equipment, auxiliary welding equipment, etc., can solve the problems of poor beam accessibility and achieve the effect of solving beam accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The laser shock peening method in the embodiment comprises the following steps:

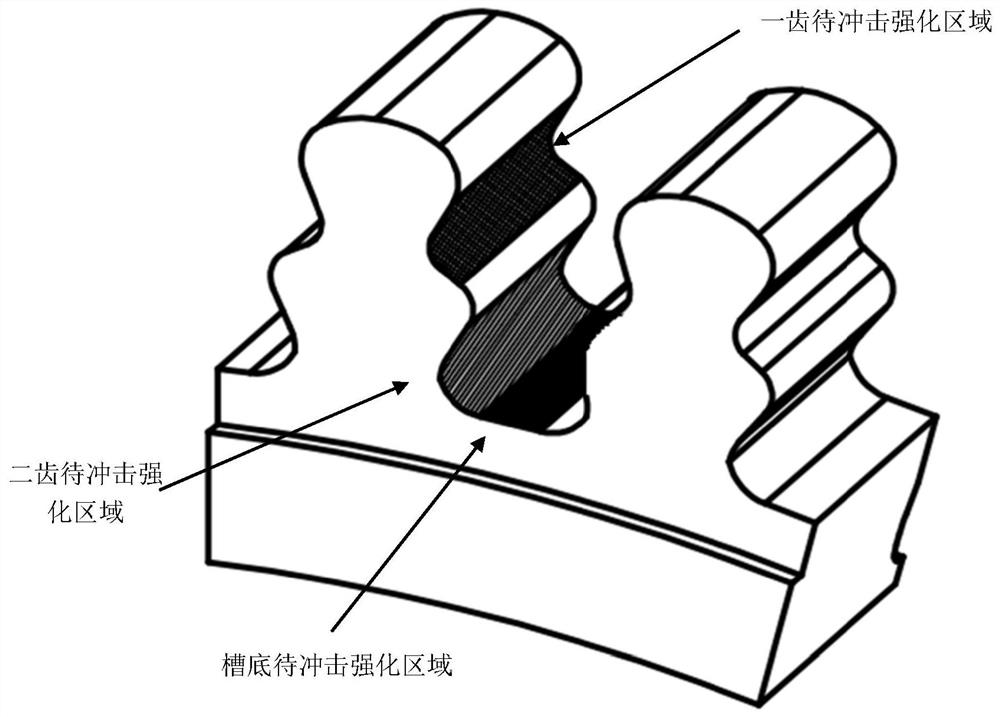

[0030] (1) According to the structural characteristics and size data of the tenon and groove of the turbine disk, the trajectory scheme of the laser shock strengthening of the tenon and groove of the turbine disk is preliminarily designed, and the area to be laser shock strengthened is determined as follows: figure 1 shown.

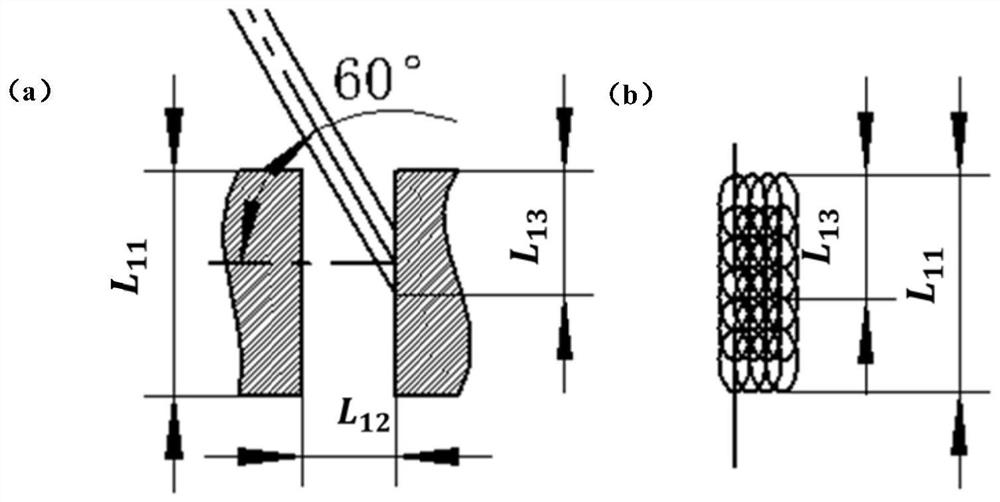

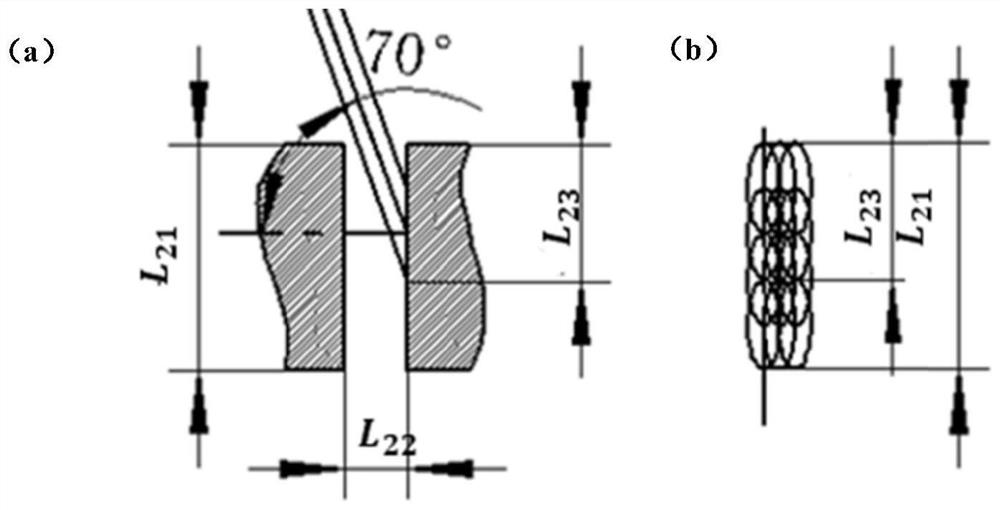

[0031] Considering the complex structure of the tenon and groove of the turbine disk, different laser shock strengthening parameters and oblique laser incident angles are adopted for different parts, and because the space of the tenon and groove of the turbine disk is narrow, the incident angle of the laser beam is not large, and the incidence from one direction is to avoid In the case of interference, it is impossible to meet the reinforcement of all positions in the tooth width direction, so the same tongue and groove is divided into two parts, the front part and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com