Non-interference laser shock peening method with two robots linked

A laser shock strengthening, dual-robot technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of high process requirements, serious interference, complex laser shock strengthening technology and equipment, to ensure quality and improve reliability. stability, avoidance of motion and effects of optical path interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

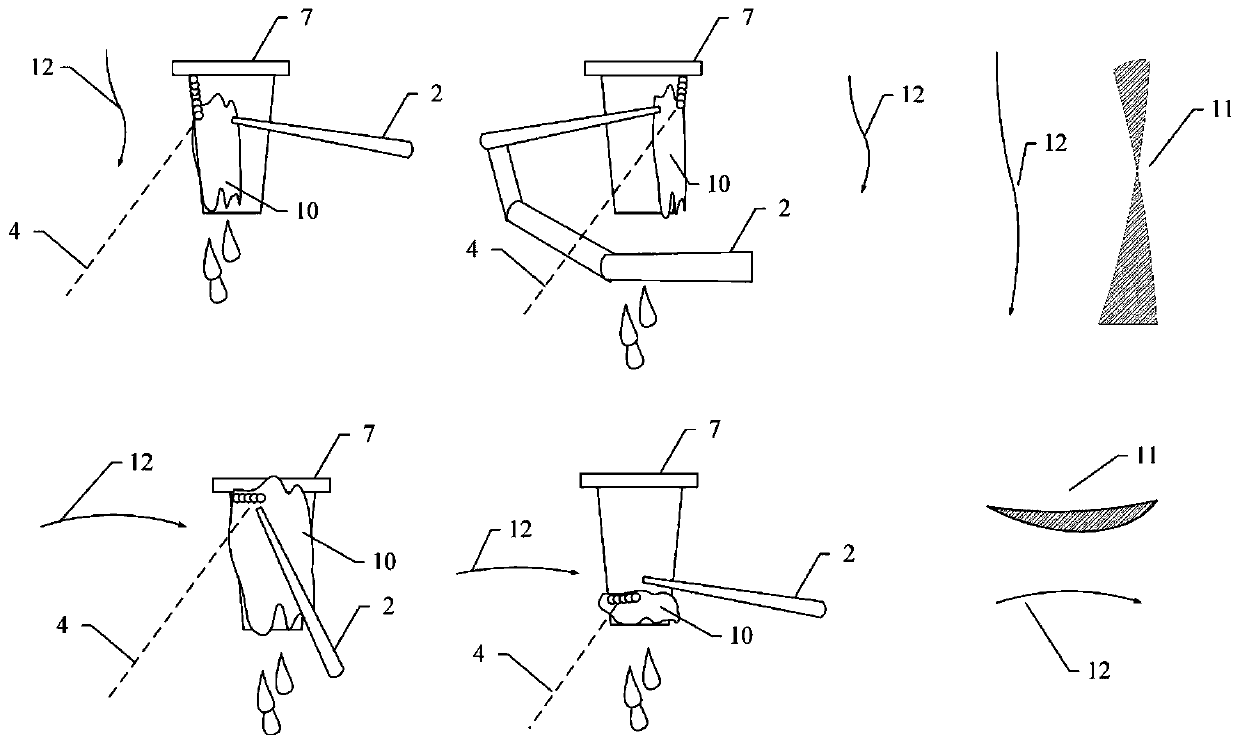

[0038] Such as Figure 1 to Figure 5 As shown, this embodiment discloses a double-robot linkage non-interference laser shock strengthening method, which uses two robots to respectively clamp and apply water to the parts to be processed, and specifically includes the following steps:

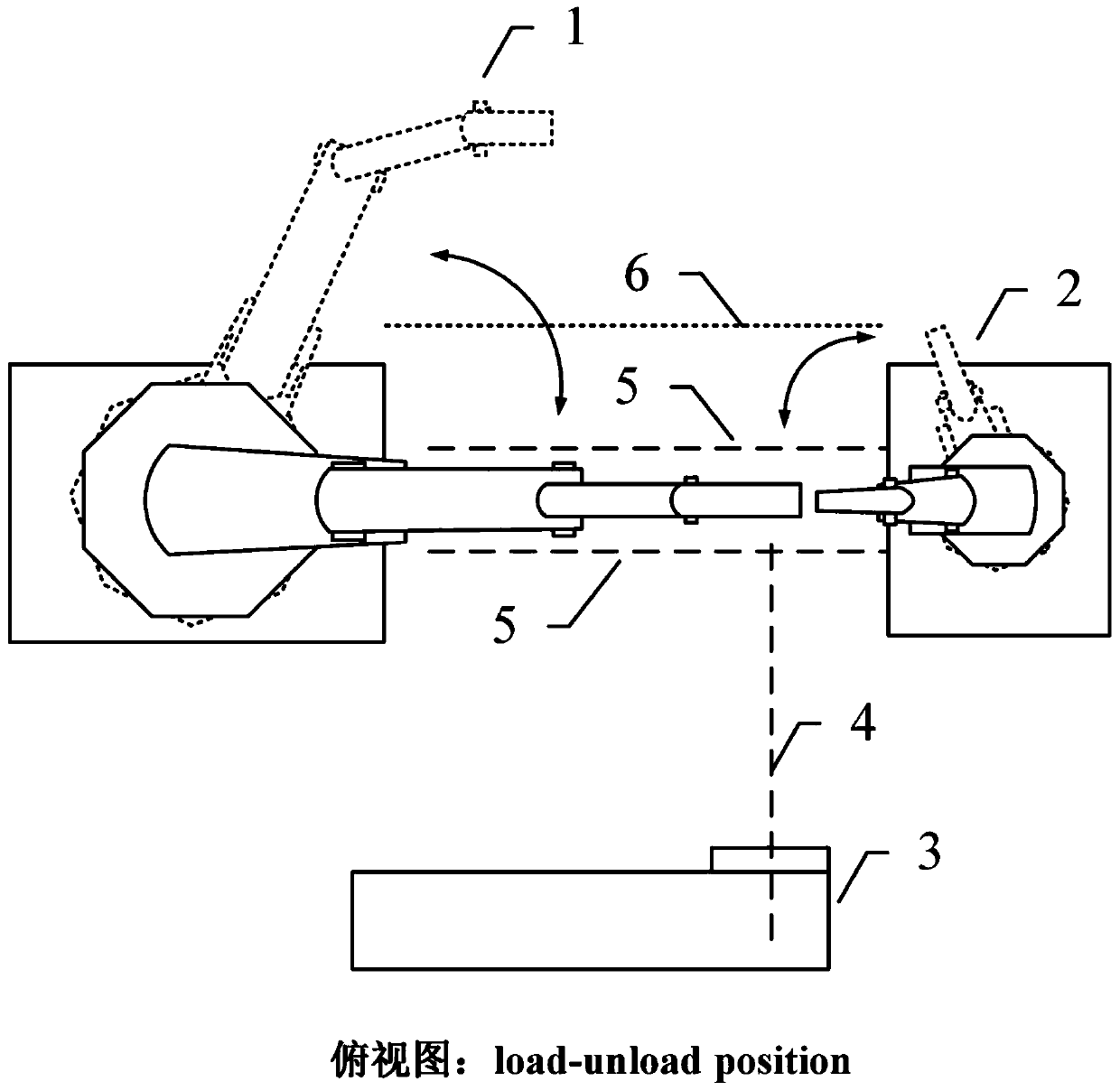

[0039] Step S1: Determine the processing area 8 according to the distance of the focal plane 5 of the pulsed laser beam 4; determine the safety plane 6 according to the external dimensions and process requirements of the part.

[0040] Specifically, the focal plane 5 in the step S1 is determined by the parameters of the optical path outside the laser system, and the focal plane 5 is the processing area 8 for laser shock strengthening. The safety plane 6 in the step S1 means that the movement of the robot in this area is safe and non-interfering.

[0041] As a preferred solution of the present invention, the safety plane 6 in the step S1 is set to a maximum size of 2 to 3 parts.

[0042] Step S2...

Embodiment 2

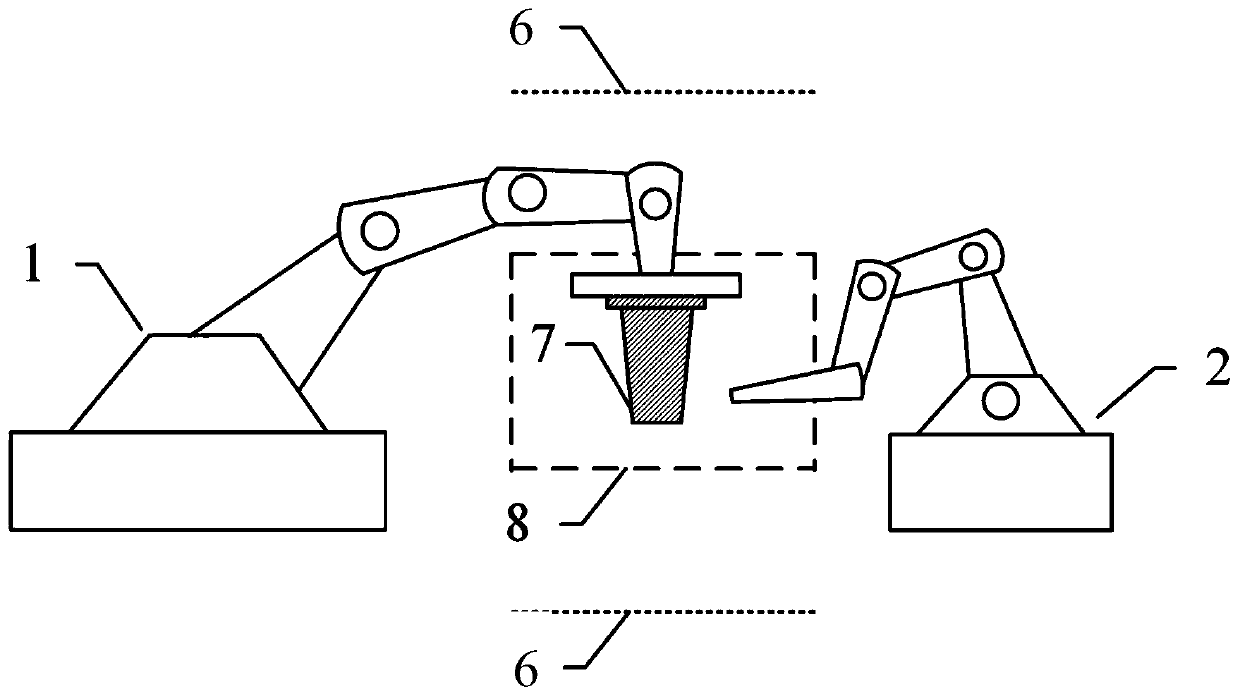

[0057] This embodiment is realized using two industrial robots with 6 degrees of freedom, in this instance:

[0058] A tool robot 1 with 6 degrees of freedom, with a load capacity of 10-400kg and a spatial repeat positioning accuracy of ±0.1mm, is designed with a special clamp for holding the blade 7 and fixing the fan blade 7 .

[0059] The other is a water coating robot 2 with 6 degrees of freedom, with a load capacity of 1 to 30 kg and a spatial repeatability positioning accuracy of ±0.1mm. It uses a customized internal pipeline to implement water coating;

[0060] The 12-axis linkage is controlled by programming to complete the spatial coordinated movement, and realizes non-interference and equal-intensity laser shock strengthening on complex curved surfaces.

[0061] Non-interference includes two aspects, one is that there is no interference in the spatial movement between parts and robots, and the other is that there is no interference between the laser beam optical path...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com