Laser peening straightening method and device for deformed blade

A laser shot peening and shape correction technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult control of grinding accuracy, complicated numerical control program writing, secondary damage of blades, etc., to improve anti-fatigue damage. Ability, control process is simple and reliable, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

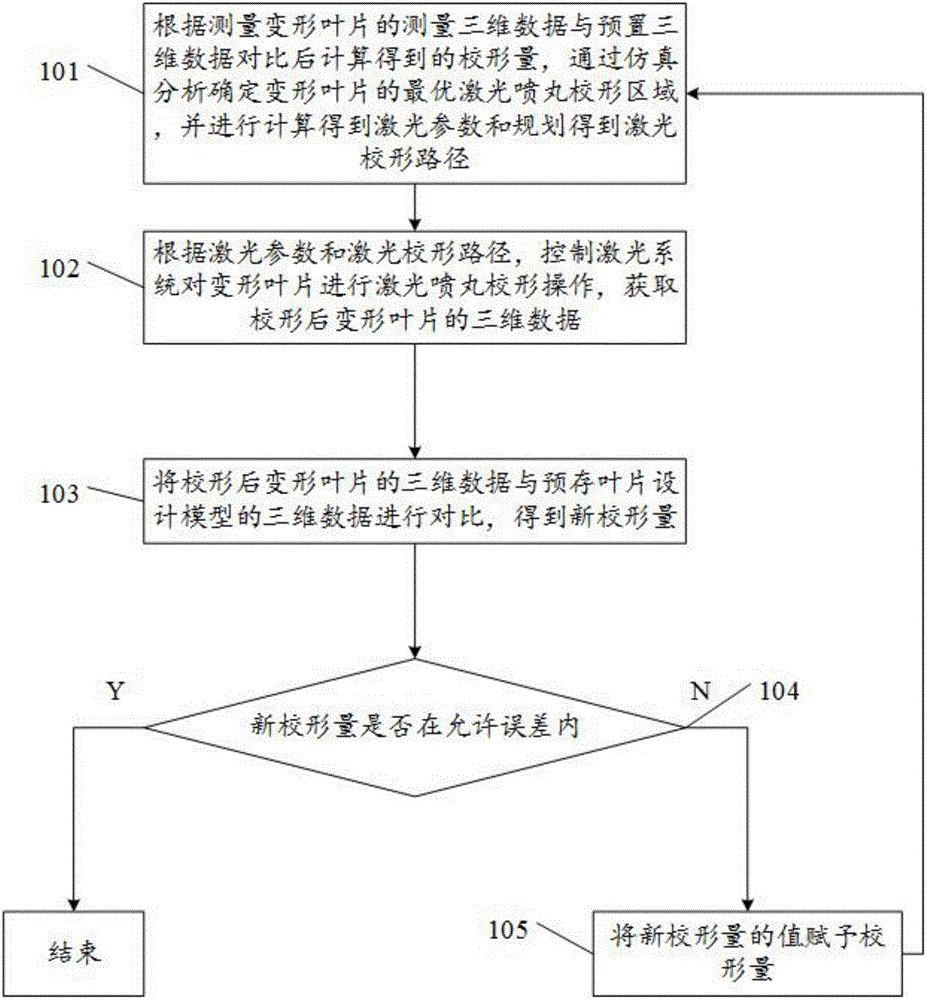

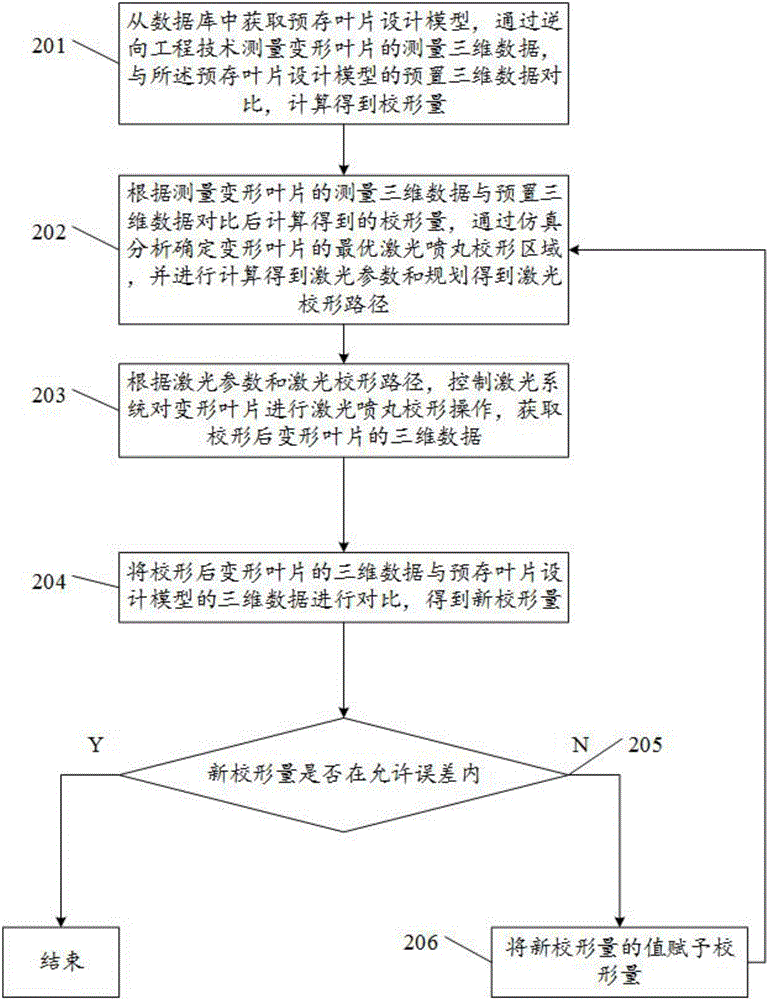

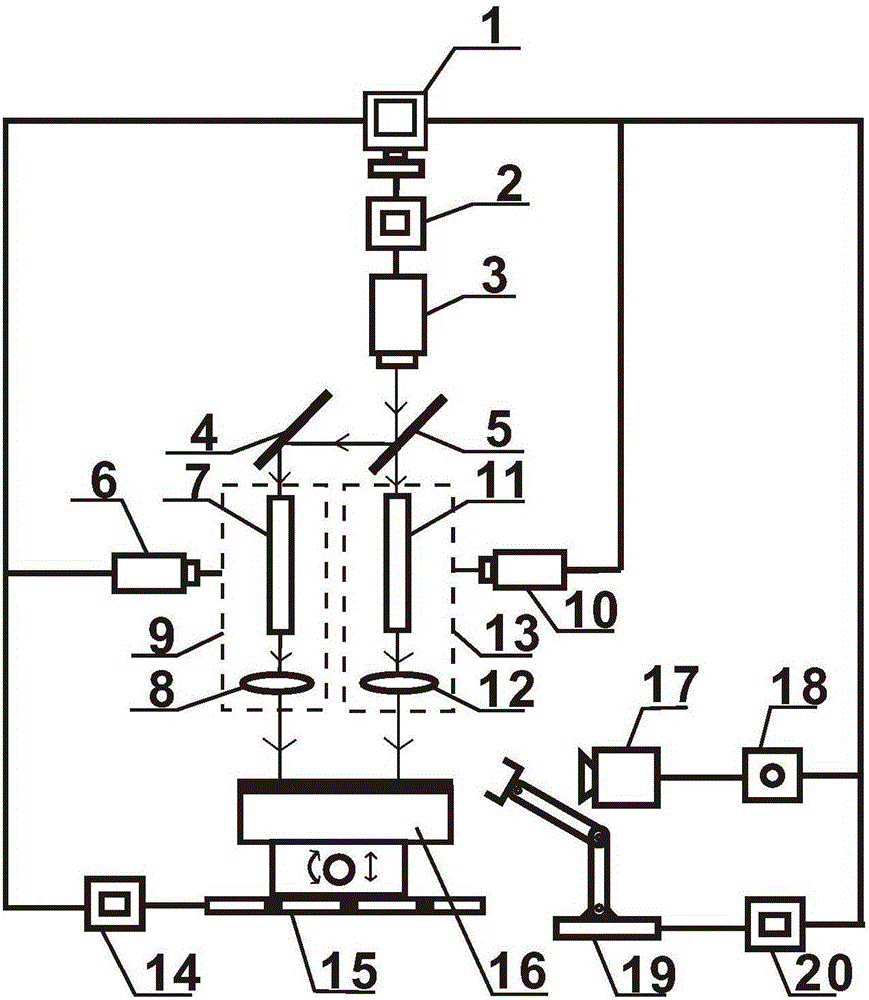

[0041]The embodiment of the present invention provides a method and device for laser peening shape correction of deformed blades. Double laser beams are used to carry out shape correction work from both ends of the shape correction path, which can shorten the shape correction time by half and improve work efficiency; The pill shape can generate residual compressive stress inside the blade, improve the fatigue resistance and corrosion resistance of the blade, and increase the strength of the blade; the blade deformation control process is simple and reliable, the cost is low, and it is easy to realize automation, which meets the requirements of precision manufacturing of aviation parts. It is especially suitable for the precise shape correction of deformed blades with out-of-tolerance torsion angles.

[0042] In order to make the purpose, features and advantages of the present invention more obvious and understandable, the technical solutions in the embodiments of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com