Pre-stressing clamp for laser peening formation of workpiece

A prestress and workpiece technology, applied in the field of manufacturing tooling, can solve the problems of lack of flexibility, the rebound of the workpiece, the inability to accurately and continuously control the prestress and the elastic pre-deformation of the workpiece, and achieve the effect of improving the processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form.

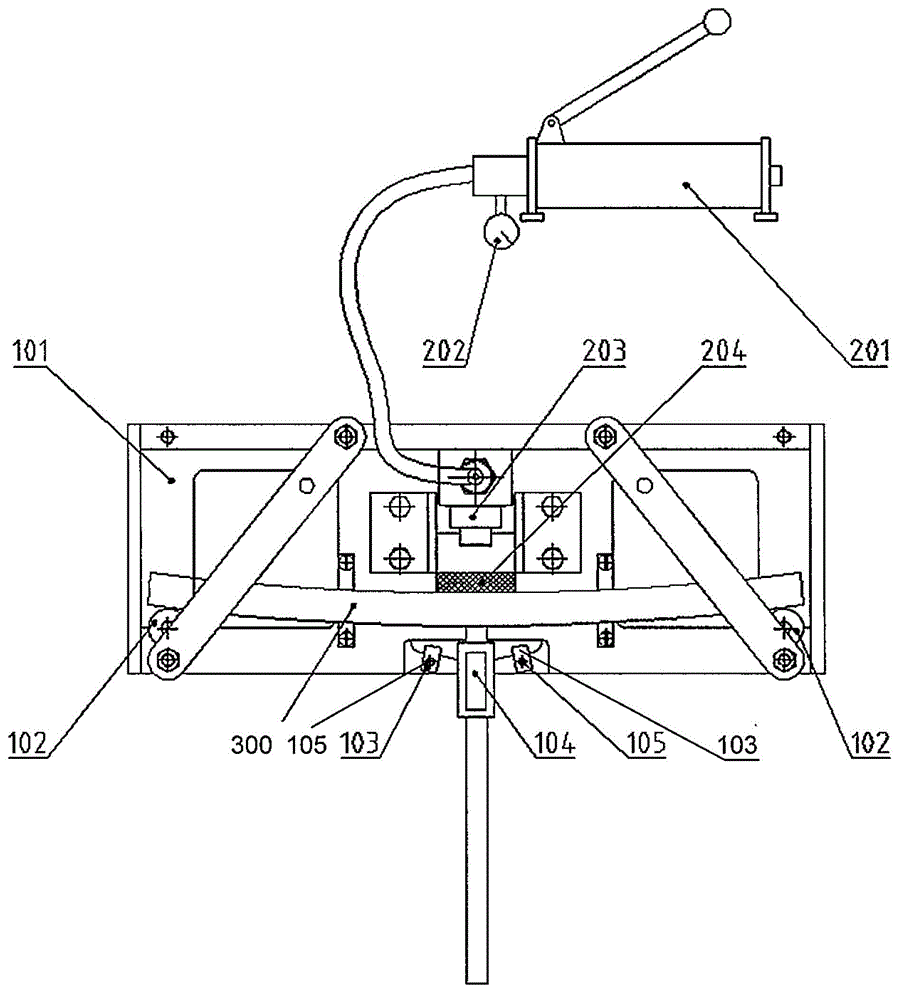

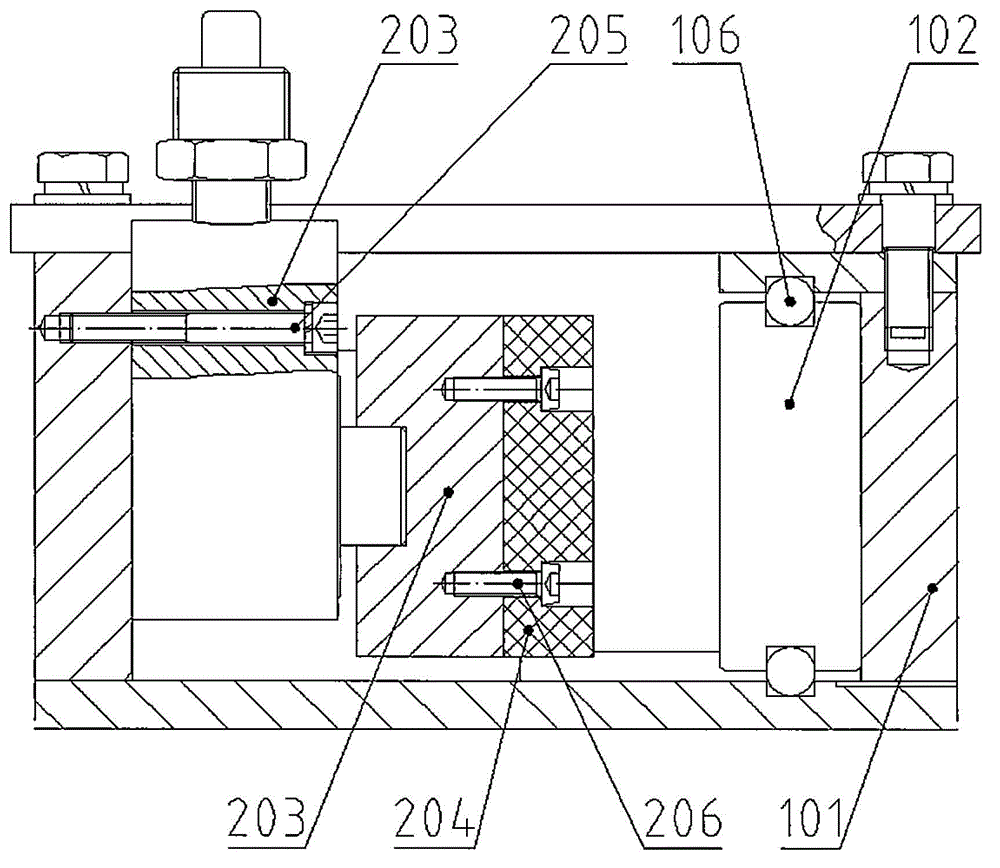

[0013] like figure 1 As shown, it shows a schematic structural view of the prestressed clamp according to the present invention.

[0014] Specifically, the prestressing fixture includes a frame 101 , supporting rollers 102 , pressing blocks 103 , electronic vernier calipers 104 and the like. The frame 101 is arranged substantially vertically. Two support rollers 102 are arranged substantially horizontally and are rotatably mounted on the frame 101, wherein the cross section of the support rollers 102 is cylindrical so that when the workpiece 300 is supported on the two support rollers 102, the support The rollers 102 are in line contact with the workpiece 300 . By tightening the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com