Method and device for laser peening correction size precision online control for welded metal plate

A laser shot peening and sheet metal technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as difficult control of precision, no laser shot peening research, etc., to improve fatigue strength, wide application range, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for on-line control of dimensional accuracy of laser shot peening correction of welded metal sheets, the specific steps of which are as follows:

[0027] Step 1: Coordinate alignment of the 3D results obtained from the actual test with the 3D CAD model of the product with the help of a 3D contour scanner, and perform comparative analysis to obtain the visualization results of the deformation of the entire part, and further determine the deformation amount of the part to be corrected and the correction path ;

[0028] Step 2, establish the relationship between the test parameters and the amount of deformation through the test, and obtain the database of the corresponding relationship between the intensity of the laser shot peening correction and the amount of deformation. The laser peening strength of the shape correction part;

[0029] Step 3, using laser shot peening equipment, according to the laser shot peening shape correction intensity and shape correctio...

Embodiment 2

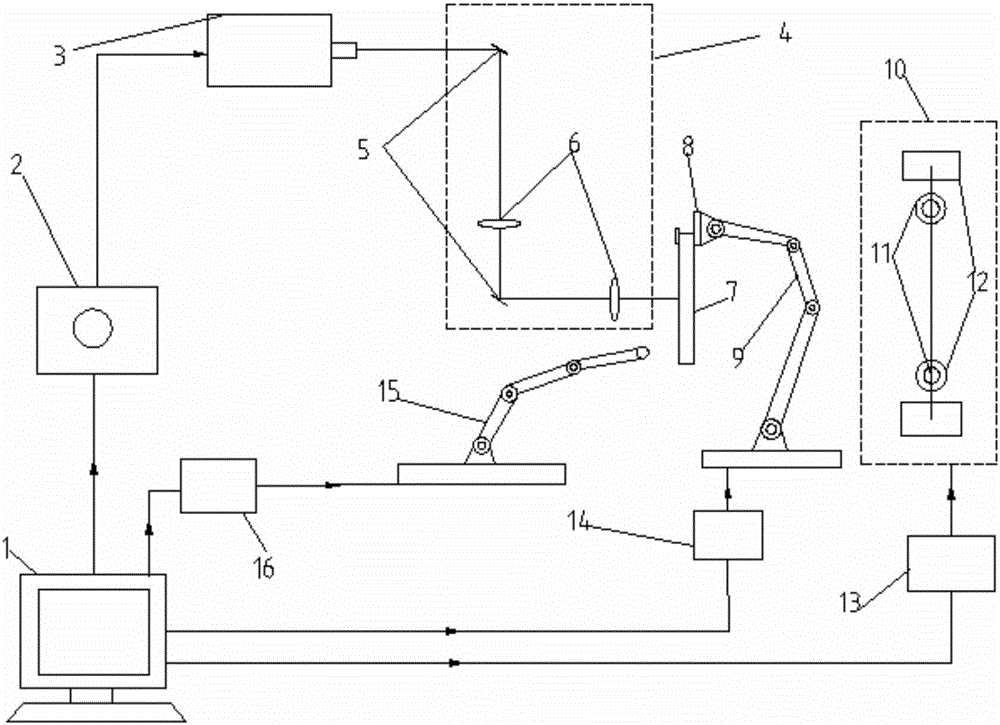

[0032] see Figure 1-2 , a device for on-line control of dimensional accuracy by laser shot peening of welded metal sheets, including a computer control system (1), a laser power supply (2), a high-power pulse laser (3), a light guide and optical path adjustment system (4), and a reflector Mirror group (5), perspective mirror group (6), weldment (7), fixture (8), manipulator (9), dynamic optical monitoring system (10), lighting source (11), measuring camera (12), dynamic Monitoring and control system (13), clamping control system (14), constraining layer water spraying system (15), water layer control system (16), energy absorbing layer (17), developer (18), and computer control system (1) Laser power supply (2), dynamic monitoring control system (13), clamping control system (14), water layer control system (16) are connected to each other; fixture (8) is fixed on the manipulator (9).

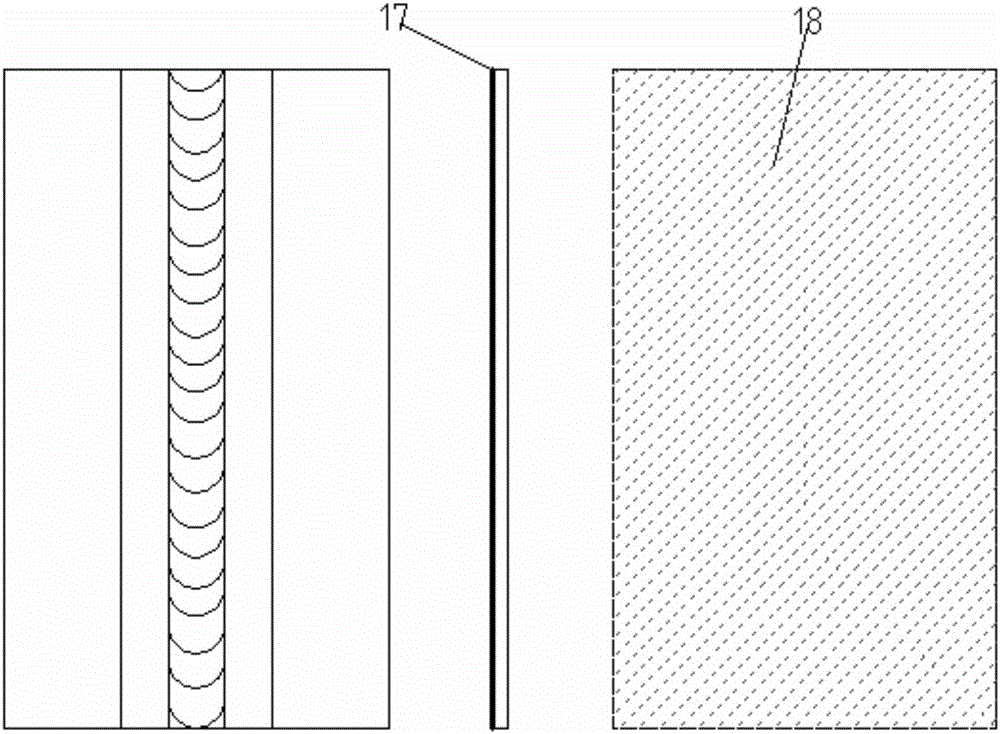

[0033] The front of the laser peened weldment is coated with an energy-absorbing layer of...

Embodiment 3

[0038] One aspect of the present invention provides a device for on-line control of the size accuracy of laser shot peening of welded metal sheets, which includes a computer control system (1), a laser power supply (2), a high-power pulse laser (3), light guide and Optical path adjustment system (4), mirror group (5), perspective mirror group (6), weldment (7), fixture (8), manipulator (9), dynamic optical monitoring system (10), lighting source (11) , measuring camera (12), dynamic monitoring control system (13), clamping control system (14), constrained layer water spray system (15), water layer control system (16), energy absorbing layer (17), developer ( 18); It is characterized in that, wherein the computer control system (1) and the laser power supply (2), the dynamic monitoring control system (13), the clamping control system (14) and the water layer control The system (16) is electrically connected; the laser power supply (2) is electrically connected to the high-power...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com