Welding residual stress measurement method based on ABAQUS

A measurement method and residual stress technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of high cost, deterioration of material performance, low cost performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with embodiment the present invention will be further described.

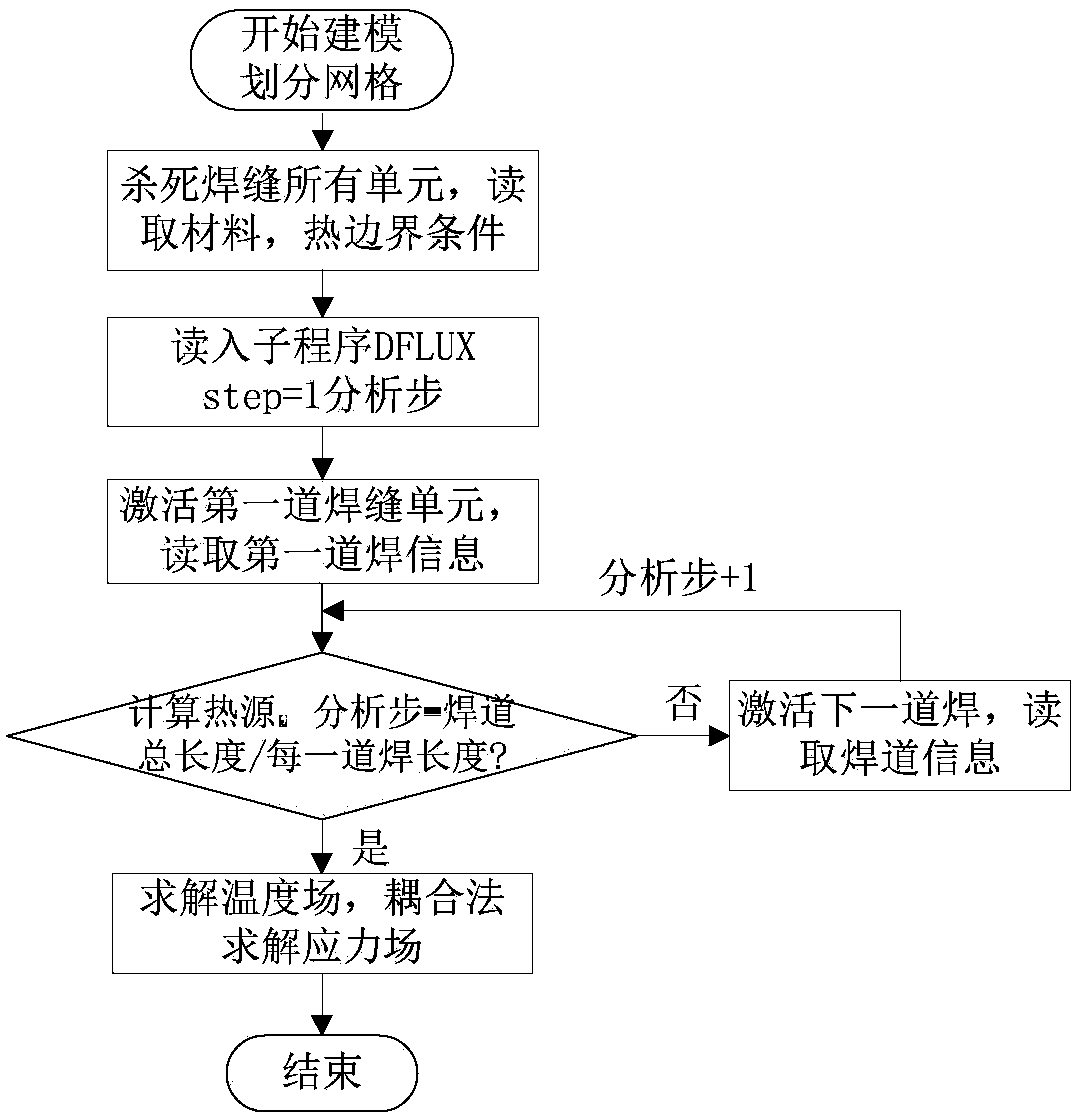

[0040] Taking T91 steel pipe as the research object, the 3D finite element model of the weldment is established according to the size, size and welding process parameters of the welded workpiece, and the numerical simulation of the 3D geometric model is as follows: figure 1 shown.

[0041] Mesh division: The grid division of the weld and its surrounding area is relatively fine, which can describe the stress field and temperature field of the weldment more specifically. The grid spacing of other parts of the weldment will be relatively large, which is convenient for measurement and reduces the amount of calculation. The global grid division diagram is as follows figure 2 shown.

[0042] Establishment of material database: When welding metal, the physical state of the weld metal undergoes a change from elastic body → elastoplastic body → plastic body → elastic body, so the differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com