Capacitor box shell welding clamping device and robot workstation

A technology for welding robots and capacitor boxes, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., which can solve the problems of difficulty in ensuring stable welding quality of the box shell, frequent replacement of box mouth fixtures, and high labor intensity of workers, and achieves a simple structure , Improve welding quality and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

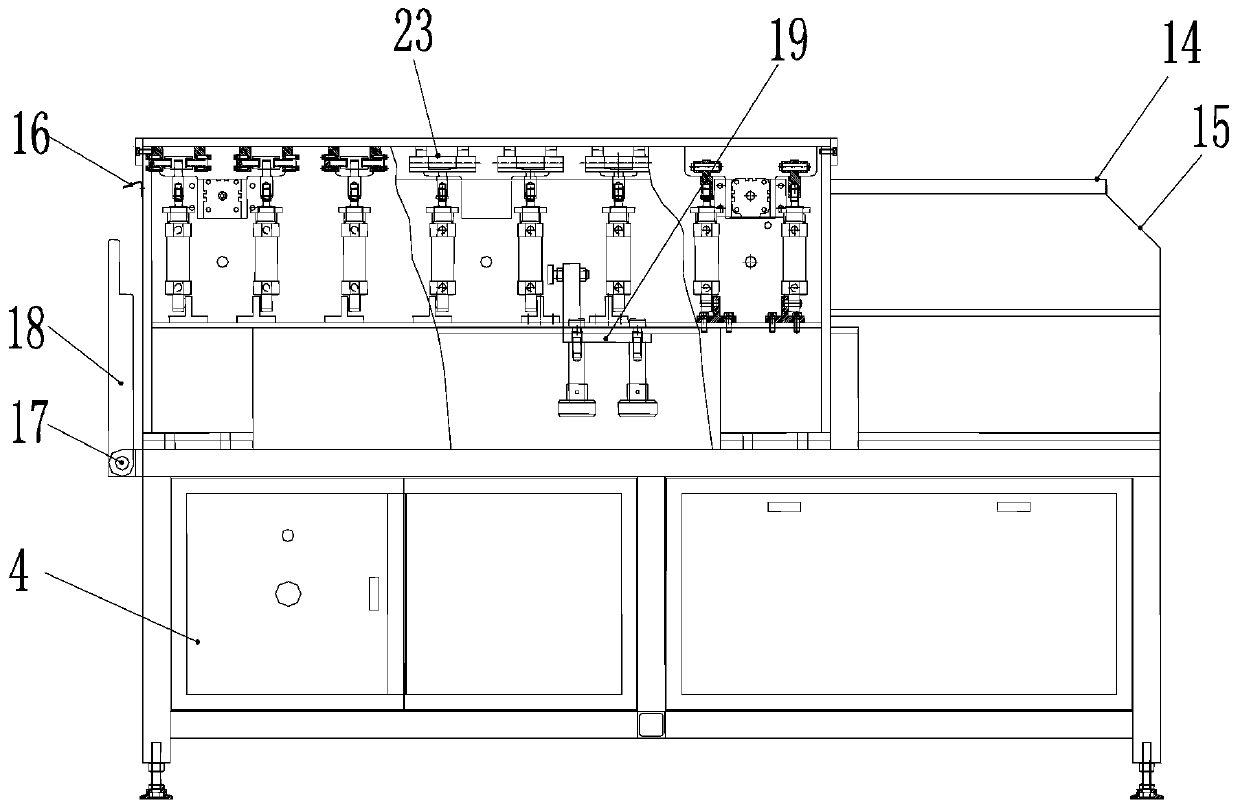

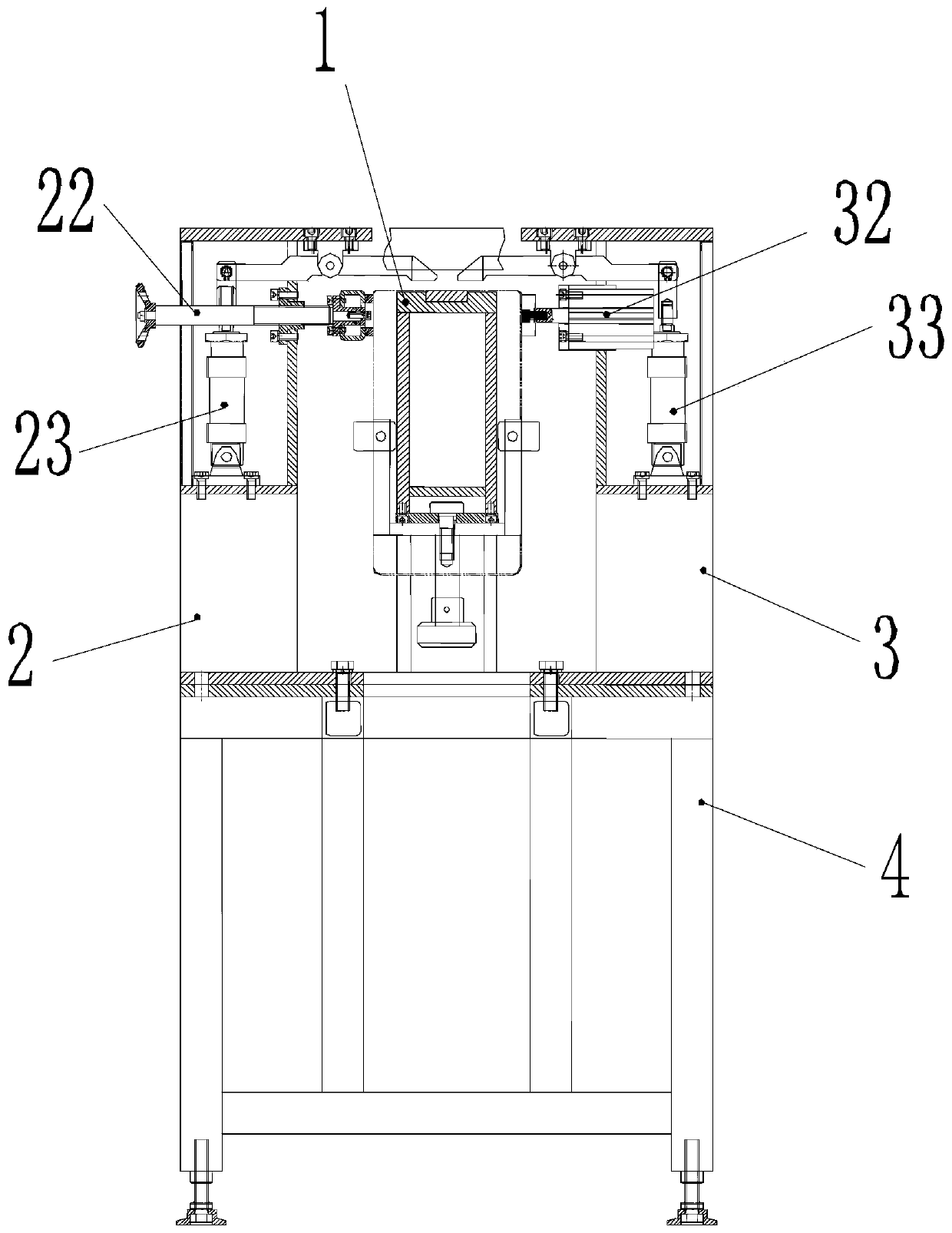

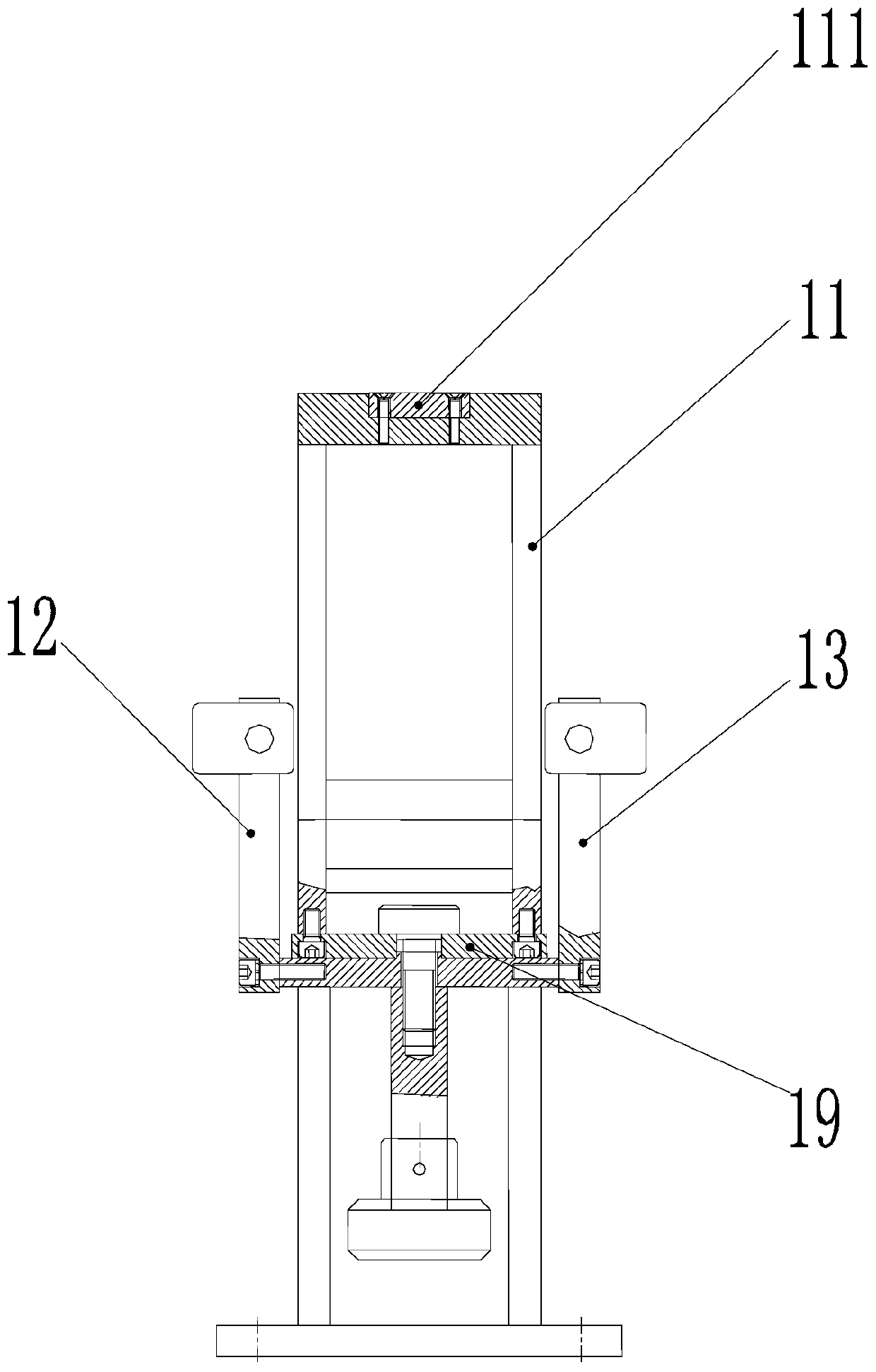

[0040] A capacitor case shell welding robot workstation includes a welding robot and a capacitor case shell welding clamping device. The capacitor case welding clamping device includes a longitudinal seam welding tool, and a case cover and a lifting and climbing welding tool; a transmission device is arranged between the longitudinal seam welding tool and the case cover and the lifting and climbing welding tool, such as a transmission roller, a conveyor belt; and The distance between the welding robot and the two is equal; the welding robot and the longitudinal seam welding tool cooperate with each other to weld the butt joint of the capacitor box body; the welding robot and the box cover cooperate with the hanging welding tool to weld Caps and hangers for capacitor housings.

[0041] The longitudinal seam welding tool includes a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com