A liquid-assisted forming method for preparing superoleophobic surfaces

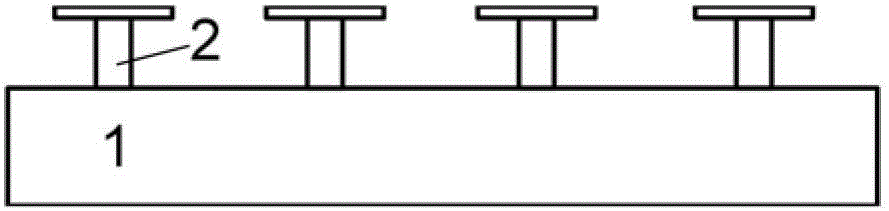

A forming method and superoleophobic technology, which is used in the preparation of polymer superoleophobic surface, the preparation of superoleophobic surface, and the field of liquid-assisted forming method, which can solve the problem of poor regularity of filament arrangement, high price, secondary Due to the limited depth of the groove structure and other problems, the effects of low preparation cost, simple equipment and easy batch preparation are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

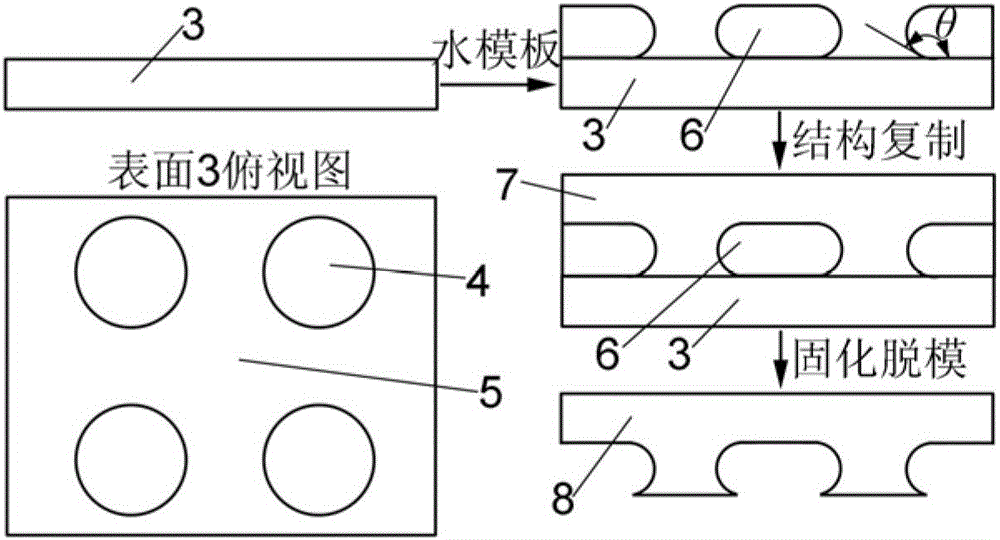

[0028] Use a silicon wafer as a flat surface for treatment, use 5% HF solution to etch the silicon wafer, etch for 5 minutes, take it out and clean it. Due to the hydrophilic nature of silicon, the treated silicon wafer surface has a smaller contact angle to water, and water spreads easily on it.

[0029] Cylindrical array structure templates were prepared by replica molding method using PDMS, the diameter of the cylinders was 30 μm, and the distance between the cylinders was 100 μm. After preparation, the PDMS was immersed in 5% trichloro(1H,1H,2H,2H-perfluorooctyl) silane ethanol solution for 1 hour, and the cylindrical array structure of the PDMS template was close to the surface of the prepared silicon wafer, so that the cylindrical The contact area between the array and the silicon wafer is transformed into a dewetting area, and the contact angle is greater than 140°.

[0030] Using water as an auxiliary forming liquid, keeping the silicon wafer level, injecting water into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com