Stirring equipment for producing epoxy resin-bonded mastic

A technology of epoxy resin cement and mixing equipment, which is applied to mixers, dissolvers, mixers and other directions with a rotating mixing device, can solve the problems of easy residues, affecting the mixing process and cleaning process, and large adhesives, and achieves a high price. Inexpensive, solve difficult demoulding and difficult cleaning, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

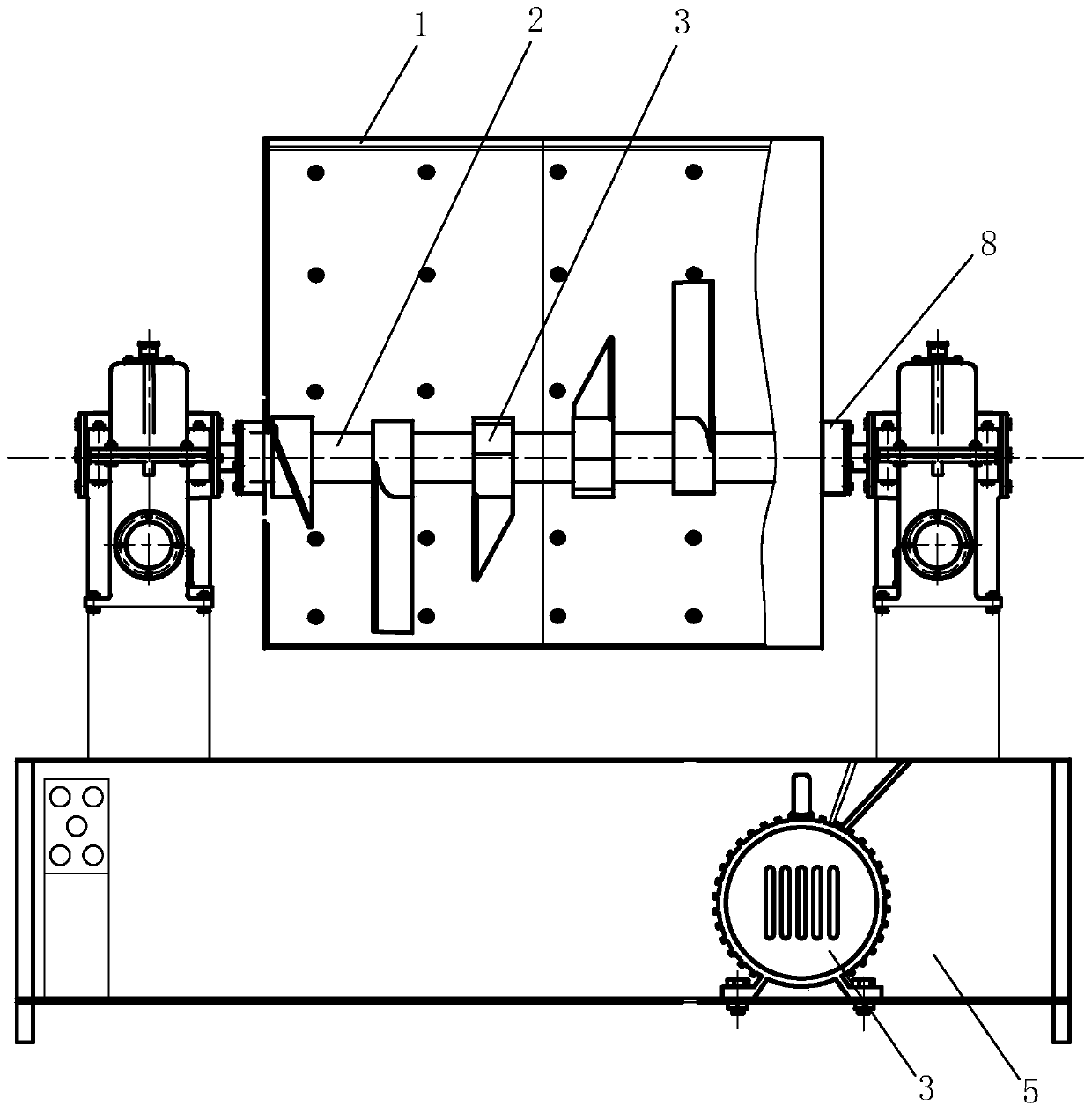

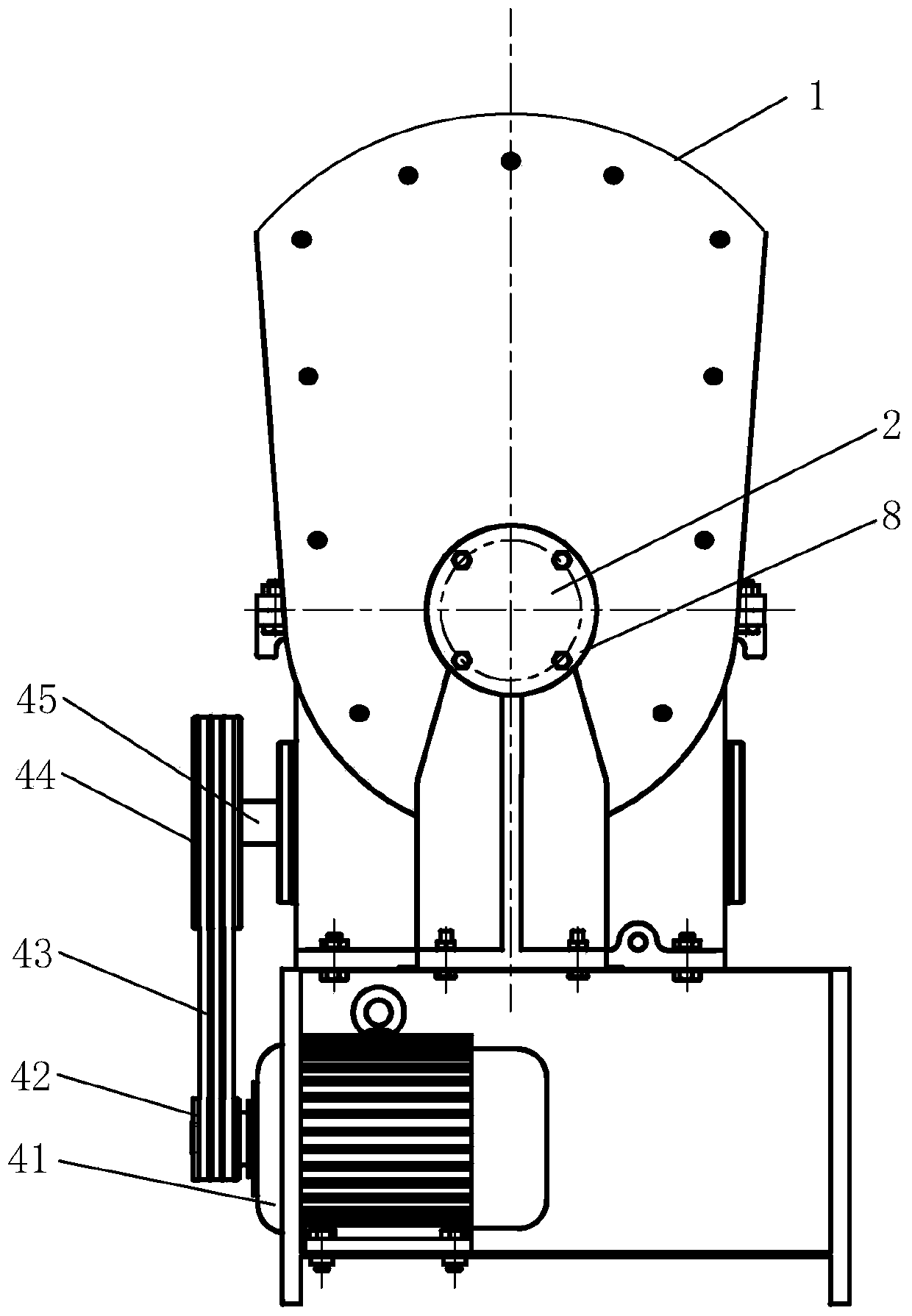

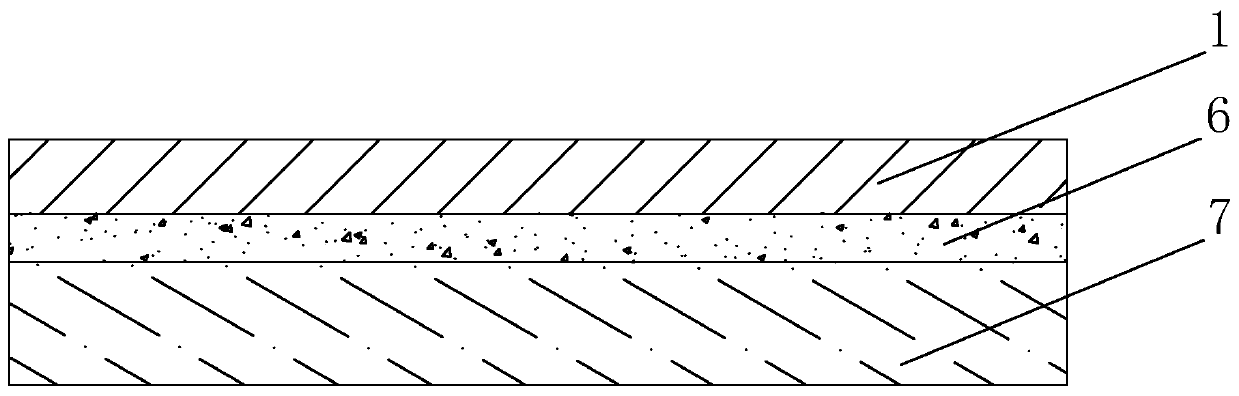

[0024] Example: A mixing equipment for producing epoxy resin mortar of the present invention includes a shell 1, a stirring shaft 2, a stirring blade 3 and a power device 4 placed in the shell 1, and the power device 4 is connected to the stirring shaft 2. The stirring shaft 2 is driven to rotate, and the stirring blade 3 is installed on the stirring shaft 2. The surface of the stirring shaft 2 and the stirring blade 3 is provided with an easy-release layer, and a smooth film layer is provided on the inner wall of the casing 1.

[0025] Both ends of the stirring shaft 2 are placed on the machine base 5 through a bearing seat, and the easy-release layer is a heat shrinkable film, which is wrapped on the stirring shaft 2 and the stirring blade 3. In this example, a heat-shrinkable film is set on the stirring shaft 2. The heat-shrinkable film is wound on the stirring shaft 2 in three layers, and then the wound heat-shrinkable film is heated and shrinked with a hot air gun. The heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com