Tech, for producing sebific duct of silicon rubber and special mould core thereof

A production process, silicone rubber technology, applied in the field of new silicone rubber hose production process, can solve the problems of difficult demoulding, easy extrusion and fracture of the reinforcement layer, etc., and achieve the effect of easy demoulding, smooth inner wall and high adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiment of the present invention is characterized in that the process steps are as follows:

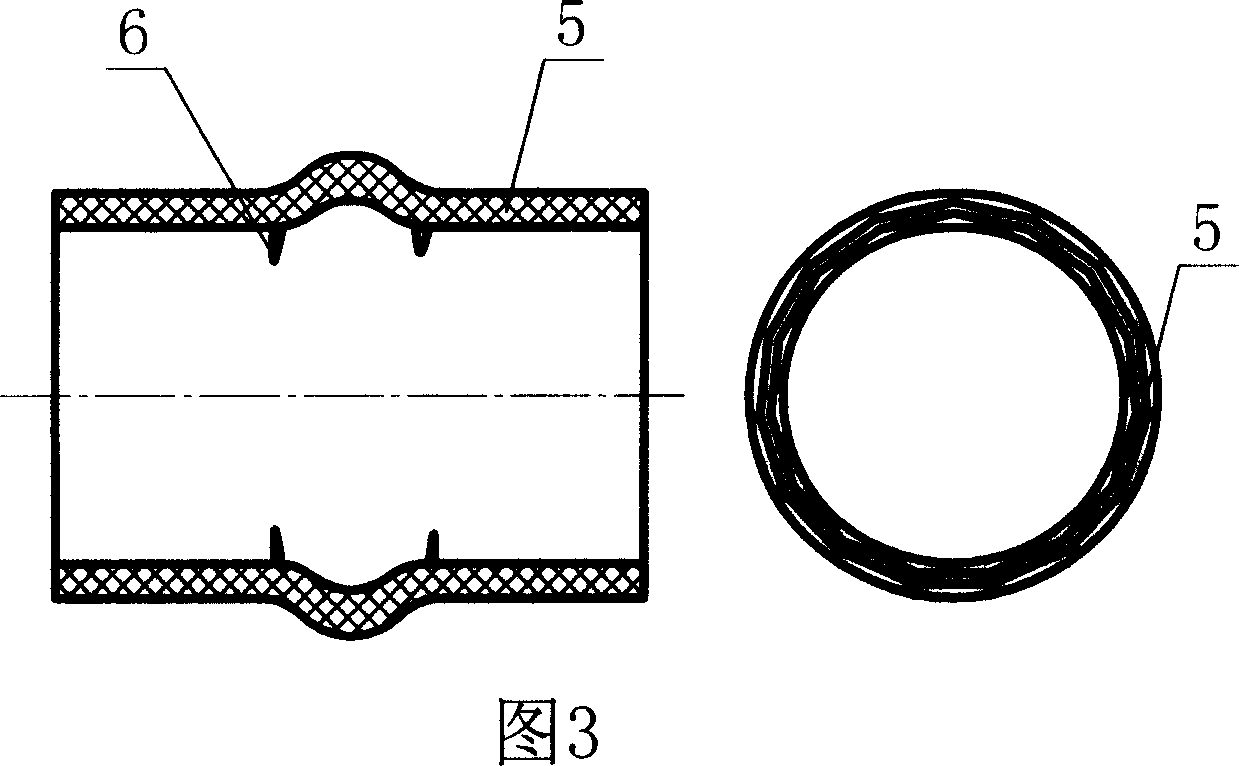

[0023] a. directly forming the rubber hose blank on the surface of the capsule 7 compatible with the inner diameter of the rubber hose 11;

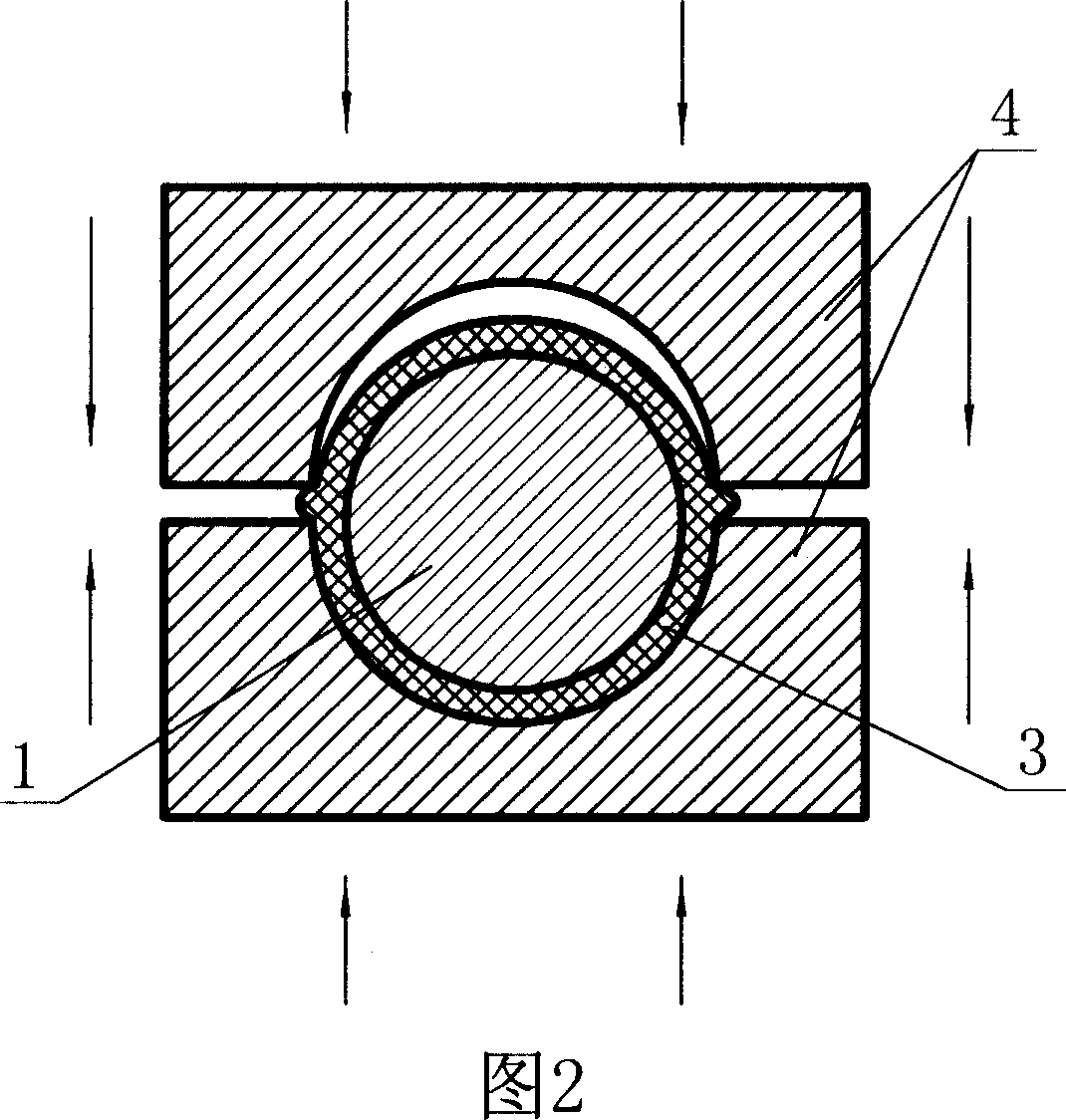

[0024] b. put the formed rubber tube blank 9 together with the capsule into the cavity of the mold 10;

[0025] c. Close the mold, inject internal pressure into the capsule, and vulcanize;

[0026] d. After the vulcanization is completed, release the pressure, pull out the capsule, and obtain the rubber hose.

[0027] Since the rubber hose has certain shrinkage during the preparation process, the outer diameter of the capsule should be slightly smaller than the inner diameter of the rubber hose.

[0028] The end of the capsule in step a is provided with an internal pressure connecting pipe 8. During specific implementation, the internal pressure connecting pipe can be set on the end of the capsule before or after forming the rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com