Method for roasting vanadium-containing raw materials to prepare vanadium-containing clinker

A vanadium clinker and raw material technology, applied in furnaces, furnace types, rotary drum furnaces, etc., can solve the problems of uneven heating of vanadium-containing clinker, low vanadium leaching rate, easy adhesion and heating, etc., and achieve low pellet production , Improve the conversion rate of vanadium, and facilitate the effect of leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

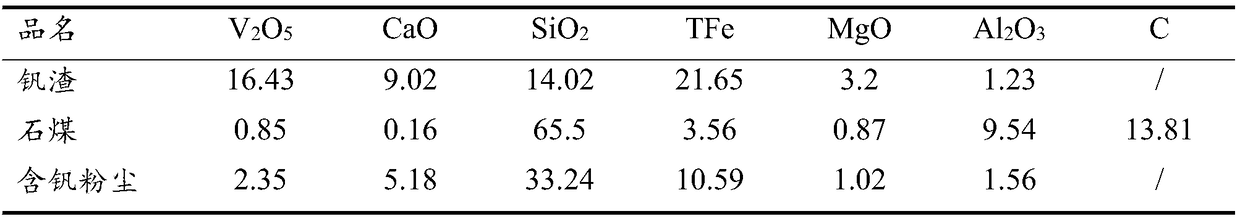

[0040] Raw materials: The typical main chemical components of the vanadium-containing raw materials (vanadium slag, stone coal, vanadium-containing dust, soda ash) selected in this embodiment are shown in Table 1.

[0041] Table 1 Typical ingredients of raw materials / (%wt)

[0042]

[0043] Soda ash is normally purchased from the market, industrial grade, Na 2 CO 3 The weight percentage is ≥98%.

[0044] The raw material vanadium slag, stone coal, vanadium-containing dust and soda ash are respectively loaded into corresponding high-level silos. The main raw material vanadium slag shall not be less than 60 tons, stone coal and vanadium-containing dust shall not be less than 10 tons, and soda ash shall not be less than 20 tons. According to the capacity of the mixer (the mixer in this embodiment adds 3 tons of materials each time) and the ratio of the feed (vanadium slag: stone coal: vanadium-containing dust: soda ash = (55~70): (8~12): (5) ~15): (12-22), this embodiment prefers vanad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com