A cavity structure and its preparation method

A cavity and cavity preparation technology, applied in the field of composite materials, can solve the problems of low reliability and difficult manufacturing, and achieve the effects of good adaptability, simple molding tooling, and reduced manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

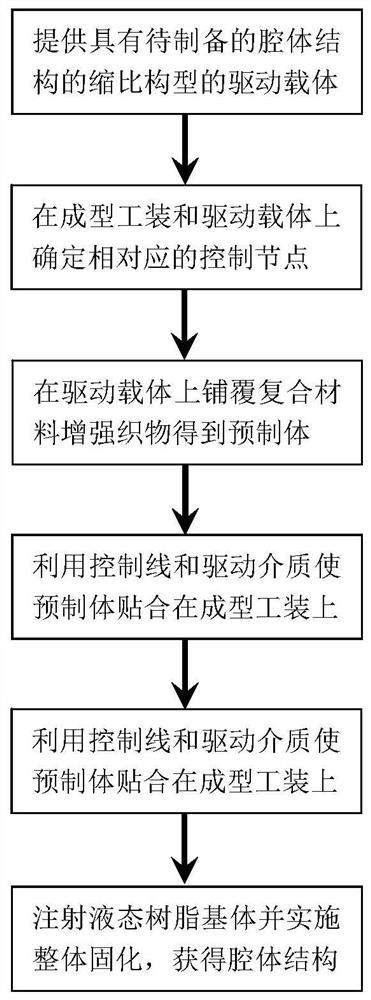

Method used

Image

Examples

Embodiment 1

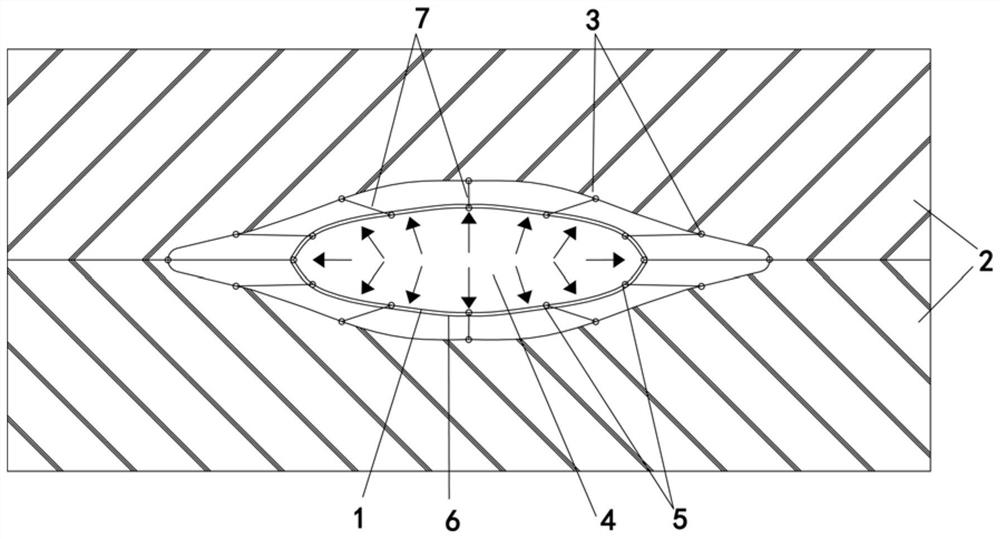

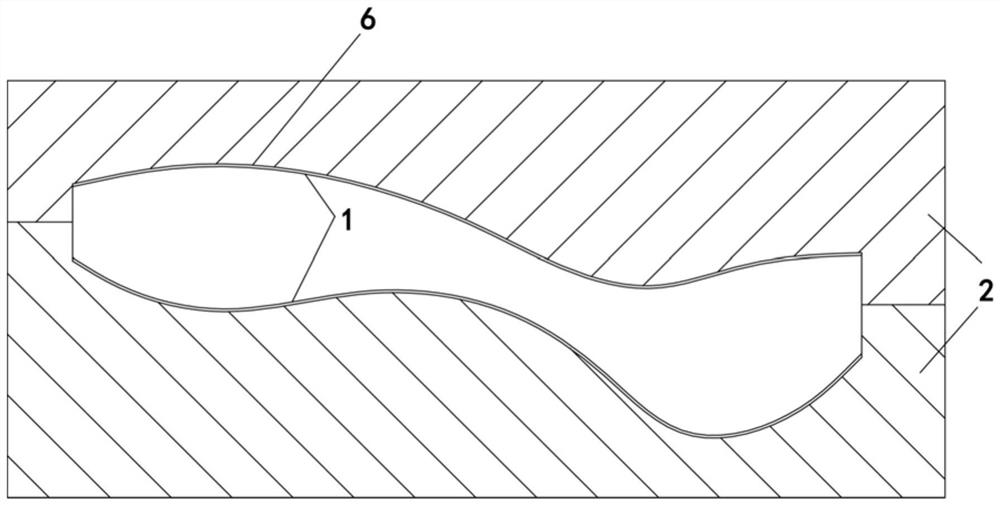

[0058] In this embodiment, a thin-wall cavity structure with special-shaped variable cross-section made of composite material is made. figure 2 As shown, the longitudinal section is as image 3 As shown, it includes driving carrier 1, forming tooling 2, driving carrier control node on the forming tooling (i.e. forming tooling control node) 3, flowing driving medium 4, control node on the driving carrier (i.e. driving carrier control node) 5, cavity Body structure prefabricated body 6, control line 7, the maximum length of the envelope of the cavity structure is 1200mm, the maximum width of the envelope is 460mm, the maximum height of the envelope is 220mm, and the wall thickness is 2.4mm. Layup is [(0 / 90) f / (45 / 0 / -45 / 90) 2 ] s ,((0 / 90) f Indicates plain weave fabric, () 2 Indicates that the layers in parentheses are cycled twice, [] s Indicates that the layers in the square brackets are laid first, and on this basis, the layers symmetrical to the above layers are laid....

Embodiment 2

[0074] The method is basically the same as that of Example 1, except that the driving carrier is made of aramid non-woven material with a breaking elongation of 400%.

Embodiment 3

[0076]The method is basically the same as in Example 1, except that the control thread is a glass fiber thread.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com