Injection mold with channel inner arc-shaped chamfer demolding mechanism

A demoulding mechanism and injection mold technology, applied in the field of injection molds, can solve problems such as difficult demoulding, limited demoulding space, etc., and achieve the effect of improving precision and precise mechanism control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

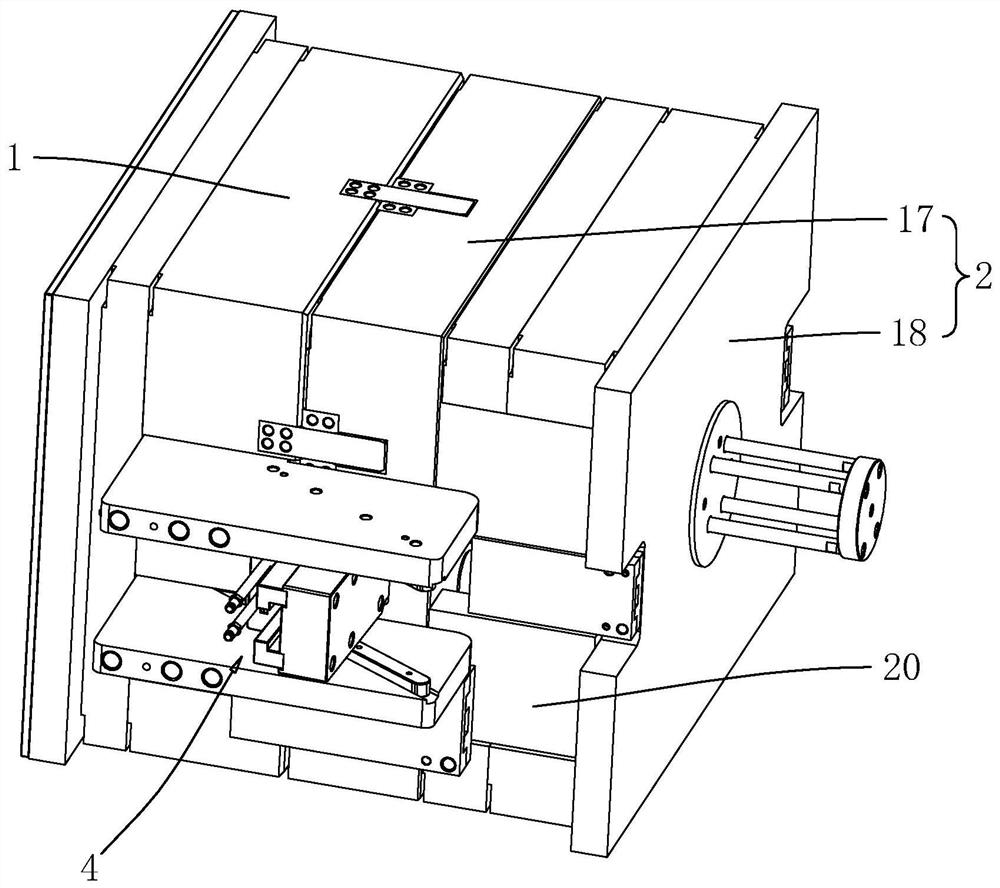

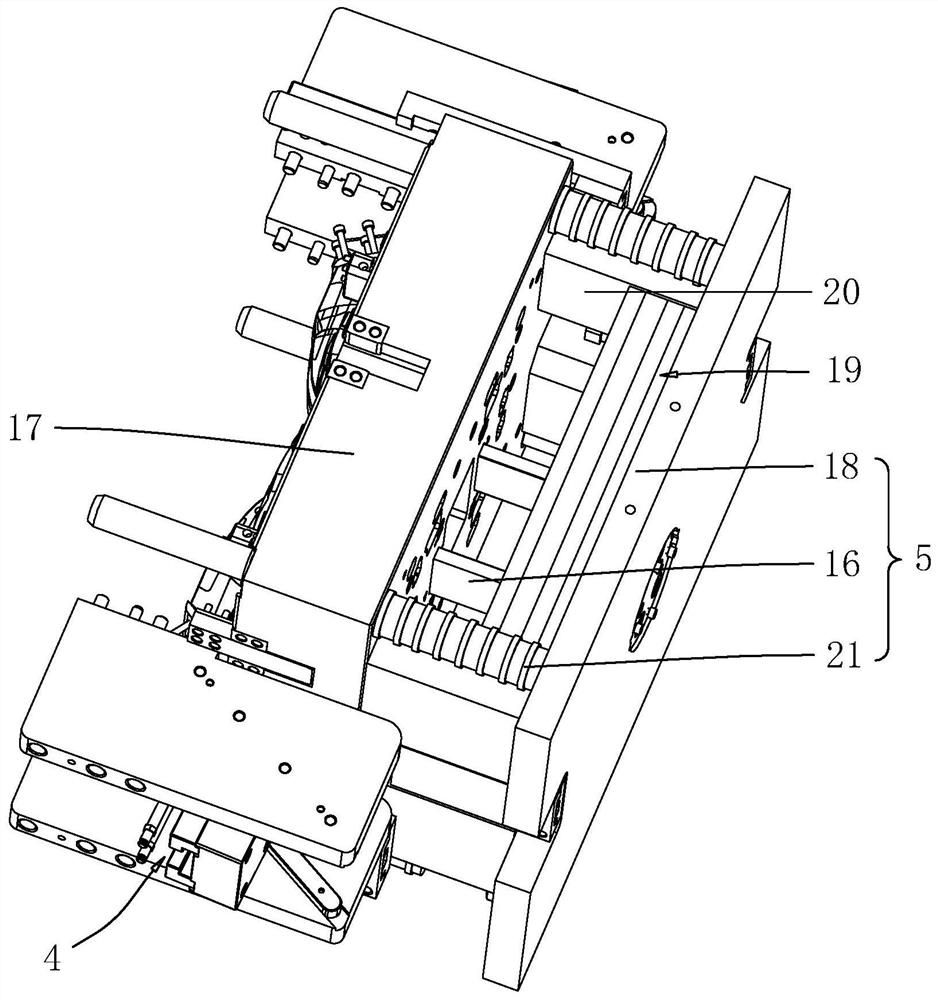

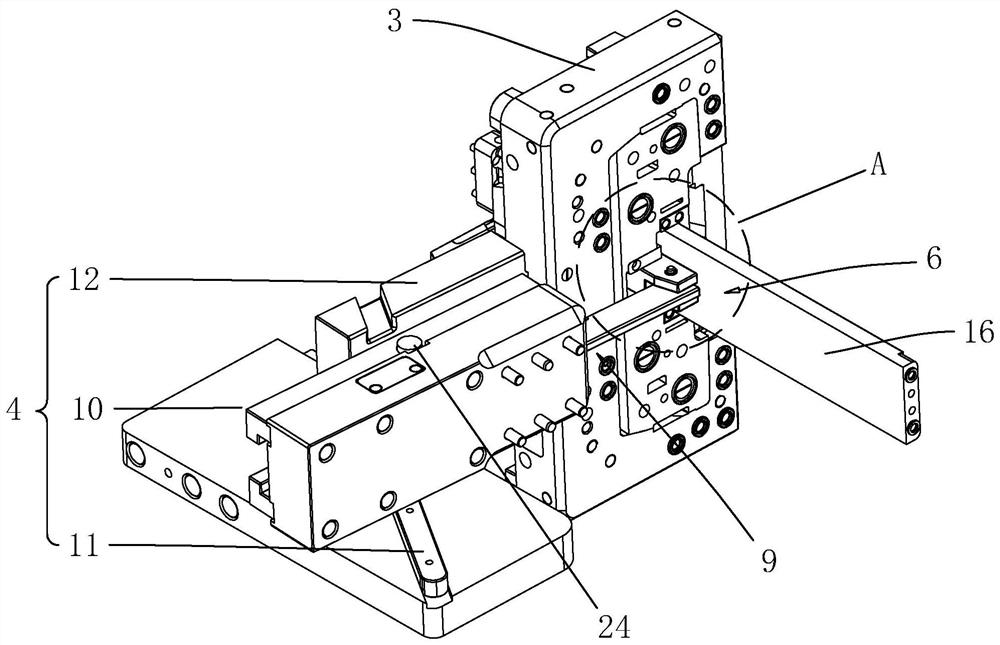

[0032] The following is attached Figure 1-5 The application is described in further detail.

[0033] The embodiment of the present application discloses an injection mold with an inner arc chamfering demoulding mechanism in the channel, combining figure 1 , figure 2 with image 3 As shown, the left mold 1 and the right mold 2 are included, and the mold cores 3 are embedded on the left mold 1 and the right mold 2, that is, the mold cores 3 are arranged in pairs, and the mold cores 3 are installed and fixed by bolts. During injection molding, a pair of mold cores 3 are generally used for combined injection molding. However, some special-shaped workpieces cannot be demolded, so another mechanism is needed to cooperate with the mold cores 3 for injection molding to facilitate demoulding.

[0034] A side core-pulling mechanism 4 is provided between the left mold 1 and the right mold 2 to cooperate with injection molding and facilitate demoulding, and a positive core-pulling me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com