Blank inner rib overturning die for cylinder workpiece with transverse inner ribs

A technology for cylinders and workpieces, which is applied in the field of flipping blank inner rib molds, can solve the problems of large machining allowance, high cost, and high machining cost, and achieve the effects of reducing shear stress, preventing material fracture, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions and specific implementation methods of the present invention will be described in detail below.

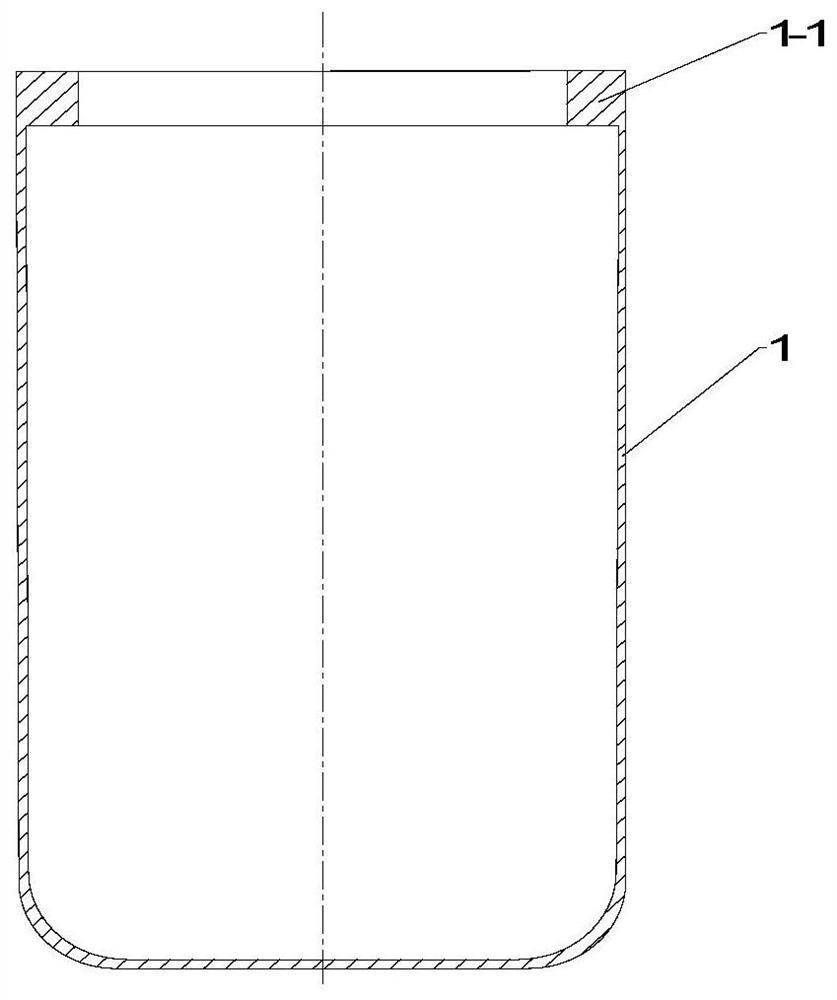

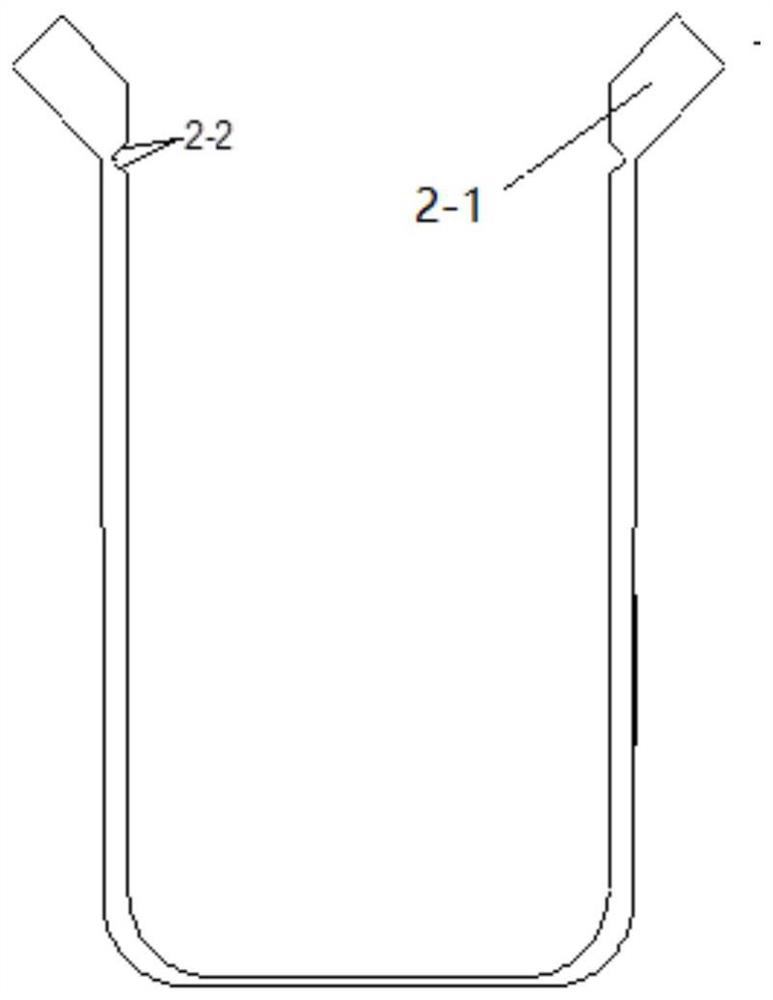

[0024] like figure 2 As shown, it is a schematic diagram of a cylinder workpiece with blank inner ribs formed by reverse extrusion; the groove of the cylinder workpiece with rough inner ribs is cut 2-2 below the blank inner ribs (the groove is 3×45°), that is, it is completed on an ordinary lathe to complete the grooving cylinder workpiece.

[0025] The grooved cylindrical workpiece is used as the blank of the inner rib mold for turning the blank.

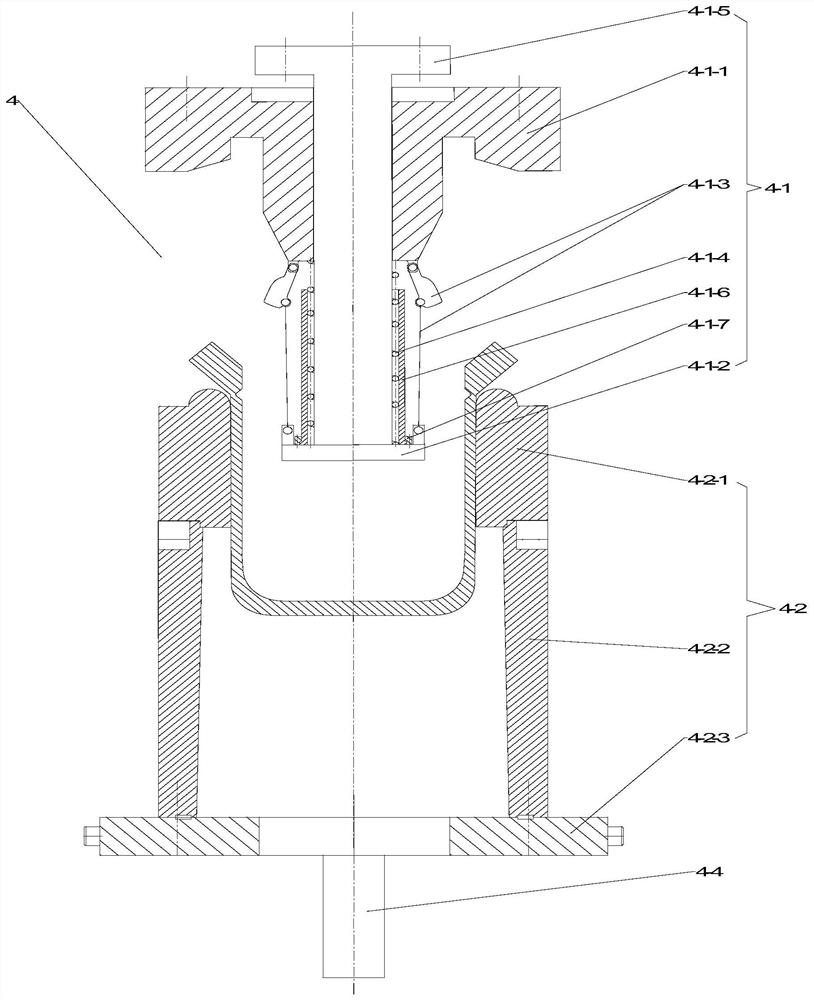

[0026] like image 3 As shown, a kind of flip blank inner rib mold with transverse inner rib cylinder workpiece of the present invention comprises punch 4-1, die 4-2, and ejector pin 4-4; described punch 4- 1 Contains punch correction ring 4-1-1, punch pressure plate 4-1-2, connecting rod turning mechanism 4-1-3, spring 4-1-4, pressure rod 4-1-5, limit tube 4 -1-6, pressure ring 4-1-7; the punch pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com