Flame-retardant glass fiber reinforced PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) composite material and preparation method thereof

A composite material and glass fiber technology, which is applied in the field of PC/ABS composite material and its preparation, can solve the problems of aggregation, affecting the uniform distribution of fibers, difficult demoulding, etc., achieve large application space, improve blending performance, and good comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

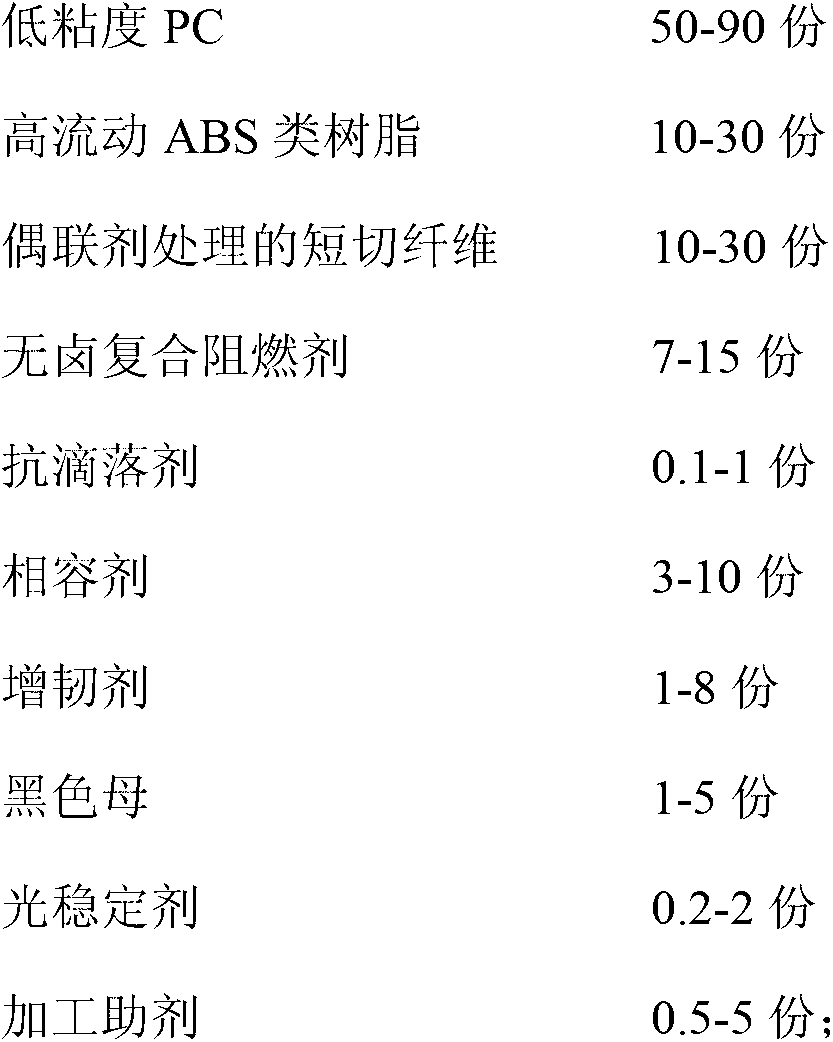

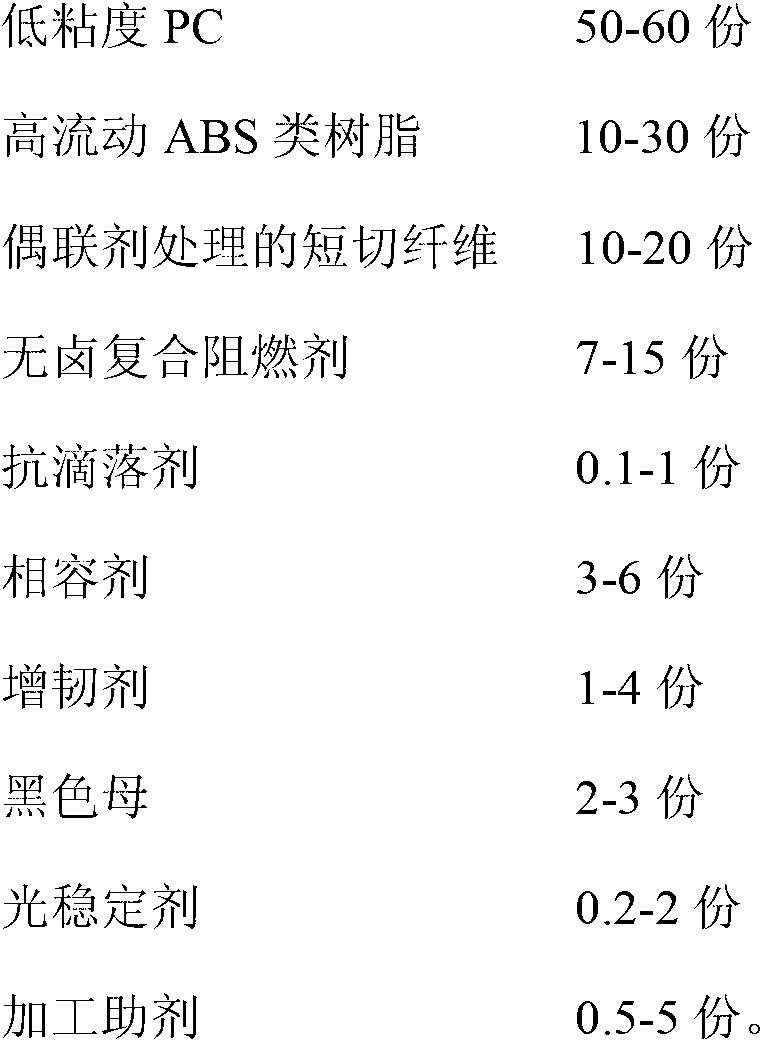

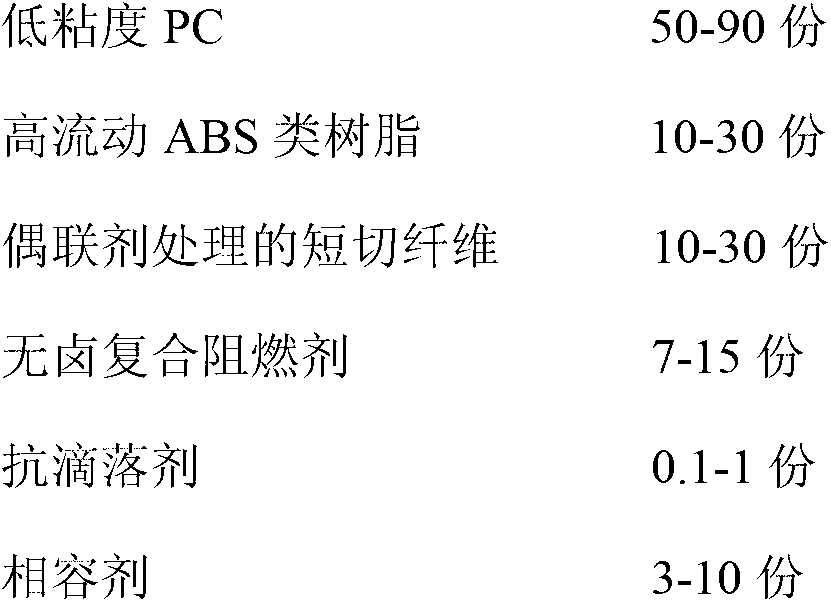

[0042] A flame-retardant glass fiber reinforced PC / ABS composite material, the composition of which is shown in Table 1 by weight.

[0043] The selected PC is German Bayer PC2405, which is a low-viscosity bisphenol A polycarbonate with a melt flow rate of 20g / min (300°C / 1.2Kg);

[0044] The selected ABS is acrylonitrile-styrene-butadiene graft copolymer (imported GP22), with a melt flow rate of 18g / 10min (10Kg, 220°C);

[0045] The selected chopped fibers are E-type alkali-free chopped fibers with a diameter of φ13 μm and a length of 3 mm, which are treated with a silane coupling agent;

[0046] The selected flame retardant is sulfonate flame retardant FR2025;

[0047] The selected black masterbatch is British Colloids SAN11821, which has a positive impact on the mechanical properties of the system;

[0048] The selected processing aid is a compound of internal and external lubricants, release agents, anti-glass fiber exposure agents, dispersants, and compatible toughening a...

Embodiment 2

[0054] The formula is shown in Table 1. The difference between Example 2 and Example 1 is that different base color masterbatches and addition ratios are selected. Example 2 uses British Colloid PC base color masterbatch 4357; the ABS used is different from Example 1, which is Shanghai Gaoqiao 8391. The melt flow rate is 32g / 10min (10Kg, 220°C); the two experimental schemes use sulfonate flame retardants alone.

Embodiment 3

[0056] The formula is shown in Table 1. The difference between Example 3 and Example 2 is that different types of flame retardants are used. In Example 3, TPP phosphorus-based flame retardants are mainly selected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com