Modified polypropylene composite material of high gloss and low shrinkage and preparation method thereof

A composite material and low-shrinkage technology, applied in the field of modified plastics, can solve problems such as low gloss, and achieve the effect of simple preparation process, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

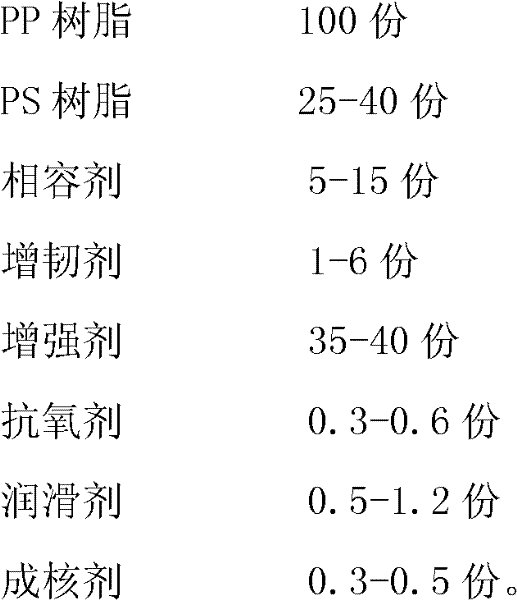

[0022] Example 1#: A modified PP composite material with high gloss and low shrinkage, the parts by weight of each component of the raw material are:

[0023]

[0024]

[0025] Concrete preparation method comprises the following steps:

[0026] (1) Take various raw materials respectively by formula ratio;

[0027] (2) Add the weighed PP resin, PS resin, compatibilizer, toughening agent, antioxidant, lubricant, and nucleating agent into the high-speed mixer for 2-4 minutes;

[0028] (3) Add the weighed enhancer to the mixture made in step (2), and mix at high speed for 3-5 minutes;

[0029] (4) Put the mixed components into a parallel twin-screw extruder to melt, extrude and granulate. The barrel temperature of the extruder is 180-230°C, and the screw speed is 400-600r / min. Melt pressure It is 1.5-2.5MPa; the vacuum degree is -0.04~-0.1MPa, that is, the modified polypropylene composite material with high gloss and low shrinkage can be obtained.

Embodiment 2

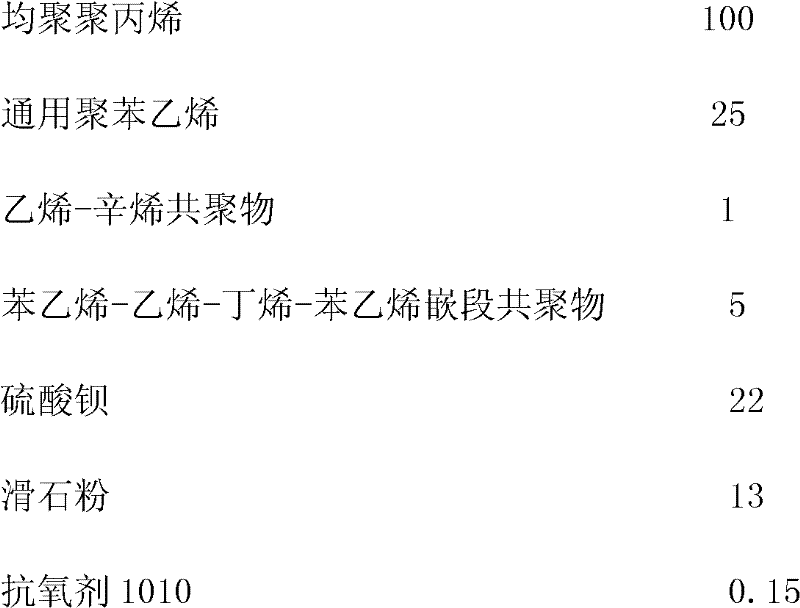

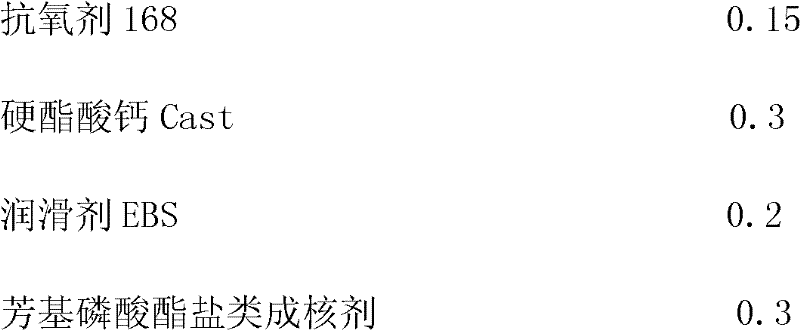

[0030] Embodiment 2#: the parts by weight of its constituent raw materials are:

[0031]

[0032] Concrete preparation method is with embodiment 1#.

Embodiment 3

[0033] Embodiment 3#: the parts by weight of its constituent raw materials are:

[0034]

[0035] Concrete preparation method is with embodiment 1#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com