High-toughness low-odor scratch-resistant polypropylene composition and preparation method thereof

A polypropylene composition and low-odor technology, which is applied in the field of high-toughness, low-odor, scratch-resistant polypropylene composition and its preparation, can solve the problem that the polypropylene composition cannot have high toughness, scratch resistance, dimensional stability, etc. problems, to achieve good application prospects, no precipitation, high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

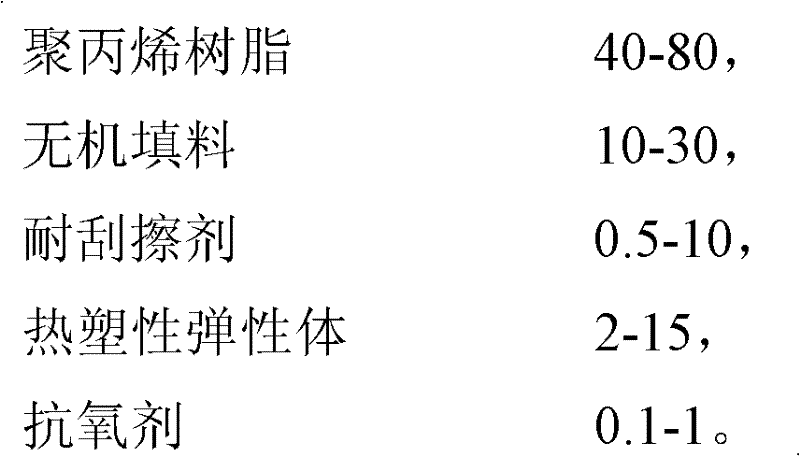

Method used

Image

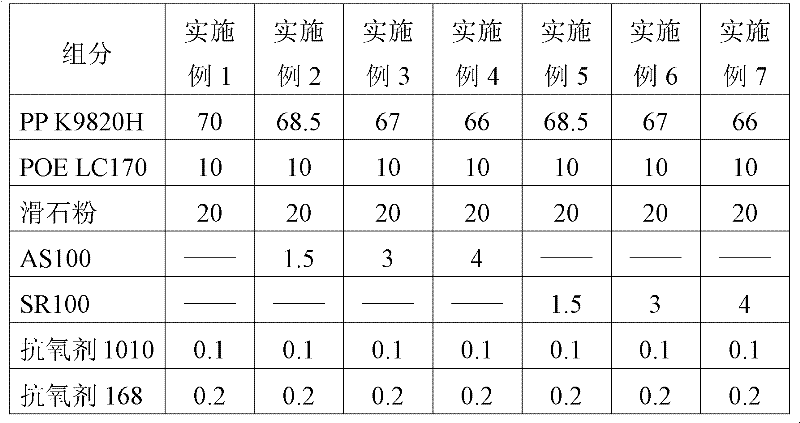

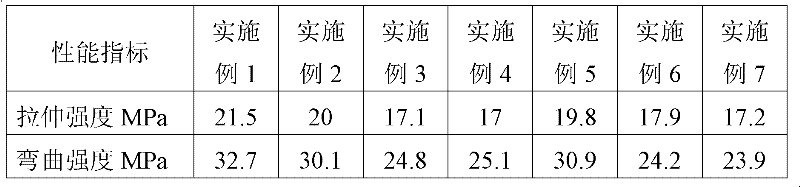

Examples

Embodiment 8

[0026] A preparation method of a high-toughness, low-odor, scratch-resistant polypropylene composition, comprising the following steps:

[0027] 40 parts by weight of copolymerized polypropylene resin, 30 parts by weight of inorganic filler calcium carbonate, 5 parts by weight of anti-scratch agent SR100, 5 parts by weight of erucamide, 15 parts by weight of thermoplastic elastomer ethylene-vinyl acetate copolymer and sulfur-containing anti-sulphur. 1 part by weight of the oxygen agent is weighed according to the proportion and added to the high-speed mixer for thorough mixing, and then the uniformly mixed material is extruded and granulated through a twin-screw extruder; the temperature of each section of the twin-screw is set at 160°C-200°C.

Embodiment 9

[0029] A preparation method of a high-toughness, low-odor, scratch-resistant polypropylene composition, comprising the following steps:

[0030] 50 parts by weight of copolymerized polypropylene, 30 parts by weight of homopolypropylene, 2 parts by weight of inorganic filler montmorillonite, 8 parts by weight of magnesium hydroxide, 0.5 parts by weight of ultra-high molecular weight silicone polymer of anti-scratch agent, thermoplastic elastomer 2 parts by weight of ethylene-propylene rubber and 0.1 part by weight of phosphite antioxidant are weighed according to the proportion and added to a high-speed mixer to fully mix, and then the uniformly mixed material is extruded and granulated through a twin-screw extruder; each of the twin-screws The stage temperature is set at 195°C-215°C.

Embodiment 10

[0032] A preparation method of a high-toughness, low-odor, scratch-resistant polypropylene composition, comprising the following steps:

[0033] 35 parts by weight of copolymerized polypropylene, 20 parts by weight of homopolypropylene, 10 parts by weight of inorganic filler mica, 8 parts by weight of kaolin, 26 parts by weight of anti-scratch agent V-Si 40426 parts by weight, thermoplastic elastomer ethylene-propylene-diene copolymer 8 parts by weight and 0.2 parts by weight of hindered phenolic antioxidant and 0.4 part by weight of phosphite antioxidant according to the proportioning ratio, added to a high-speed mixer and fully mixed, and then the uniformly mixed material was extruded by a twin-screw extruder out of granulation; the temperature of each section of the twin-screw is set at 180°C-205°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com