High-fluidity high-impact-resistance scraping-resistance polycarbonate composition and preparation method thereof

A technology of polycarbonate and composition, applied in the field of polycarbonate composition and its preparation, can solve the problems of low production cost, insufficient impact resistance and heat resistance, and achieves improved melt fluidity and impact strength, The effect of meeting flow and impact resistance requirements, excellent ductility and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

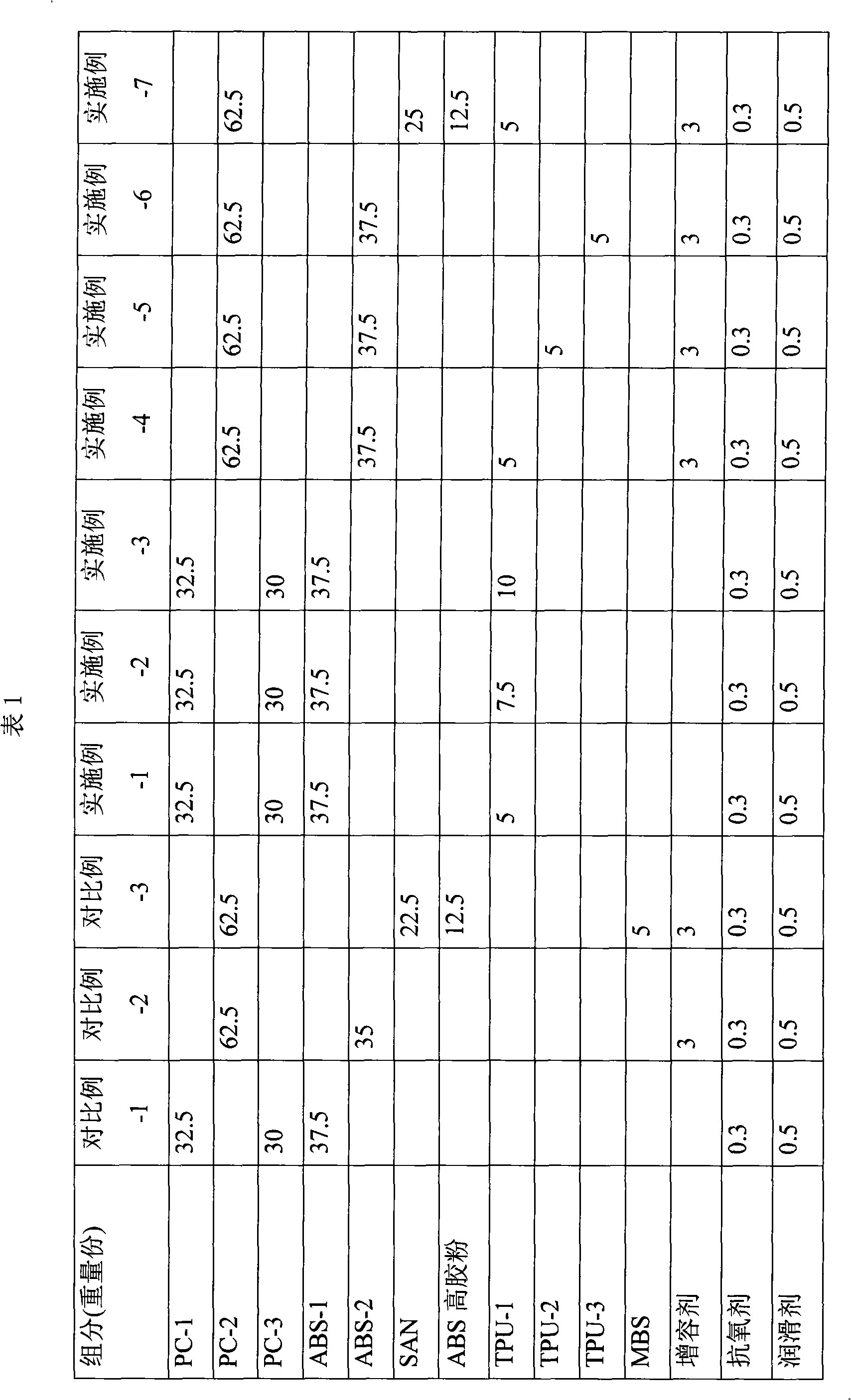

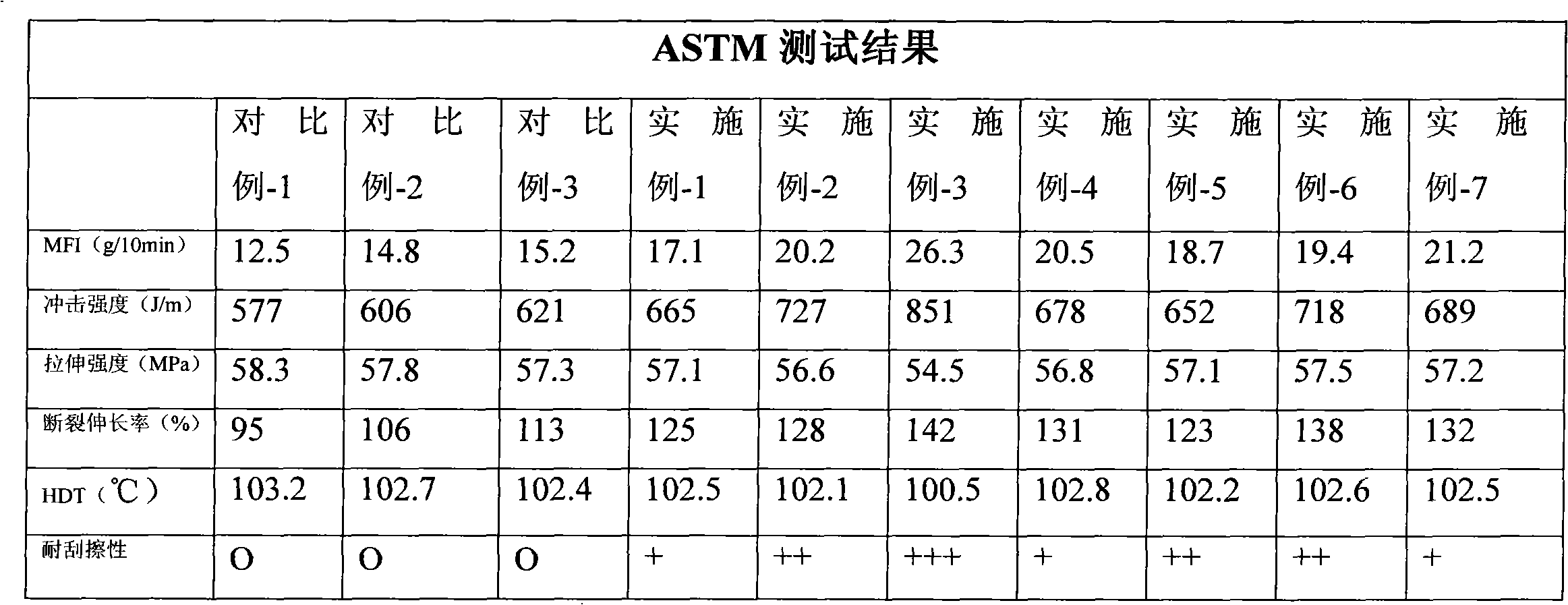

[0052] The operation process is as follows: according to the formula in Table 1, put polycarbonate, ABS, flow impact modifier TPU, compatibilizer, antioxidant, and lubricant into a high-speed mixer and mix them, and then add the mixture to the screw In the loss-in-weight feeding scale above the feeding port of the extruder, control the conveying section of the twin-screw extruder at 210-220°C, the plasticizing section at 225-245°C, the metering section at 225-240°C, and control the screw speed at 200-600rpm. Control the vacuum degree of the vacuum device in the twin-screw metering section to be less than -0.7 bar, tie the strips, water-cool, air-dry, pelletize, and dry to obtain the product.

[0053] Embodiment 1-7 and comparative example 1-3 formula are shown in Table 1 in detail

[0054]

[0055] In Table 1, the ingredients for Comparative Examples and Examples are as follows:

[0056] PC-1 is a bisphenol A polycarbonate powder with a weight average molecular weight of 3...

Embodiment 8

[0078] In this example, a high-fluidity, high-impact and scratch-resistant polycarbonate composition was prepared. With the bisphenol A type polycarbonate powder PC-125.5 weight part of weight average molecular weight 34000, the bisphenol A type polycarbonate powder PC-330 weight part of weight average molecular weight 22000, the ABS particle 38 weight parts of bulk method production , flow impact modifier polyester thermoplastic polyurethane elastomer TPU (Shao A 80) 3.5 parts by weight, compatibilizer ethylene-butyl acrylate-glycidyl methacrylate copolymer (PTW) 2.5 parts by weight, antioxidant Add 0.2 parts by weight of agent B9000, 0.3 parts by weight of lubricant PETS, add in the high-speed mixer and stir for 10min, then add the mixed material into the Brabender weight loss feeding scale above the Berstorff UTX 25mm twin-screw extruder, control The feed rate is 20Kg / h, the screw speed is 300rpm, the conveying section of the extruder is 215°C, the plasticizing section is 2...

Embodiment 9

[0080] In this example, a high-fluidity, high-impact and scratch-resistant polycarbonate composition was prepared. With bisphenol A type polycarbonate powder PC-171.5 weight part with weight-average molecular weight 28000, injection molding grade SAN particle (nitrile content 25%) 12.5 weight part, ABS high rubber powder (glue content 50%) 10.5 weight part, flow Impact modifier polyester thermoplastic polyurethane elastomer TPU (Shao A 85) 5 parts by weight, antioxidant B9000.2 parts by weight, lubricant PETS 0.3 parts by weight are added in a high-speed mixer and stirred for 10 minutes, and then mixed The material is put into the Brabender loss-in-weight feeding scale above the Berstorff UTX 25mm twin-screw extruder, the feed rate is controlled at 20Kg / h, the screw speed is 300rpm, the conveying section of the extruder is 220°C, the plasticizing section is 240°C, and the metering section 235°C, the vacuum degree of the vacuum device downstream of the extruder is -0.7 bar, wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com