Flame-retardant heat-resisting high-strength ABS (Acrylonitrile Butadiene Styrene) modified material and preparation method

A technology of modified materials and flame retardants, which is applied in the field of ABS modified materials and its preparation, can solve problems such as large warping deformation, affecting strength, and pollution, and achieve good heat resistance, good flame retardancy, and good heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

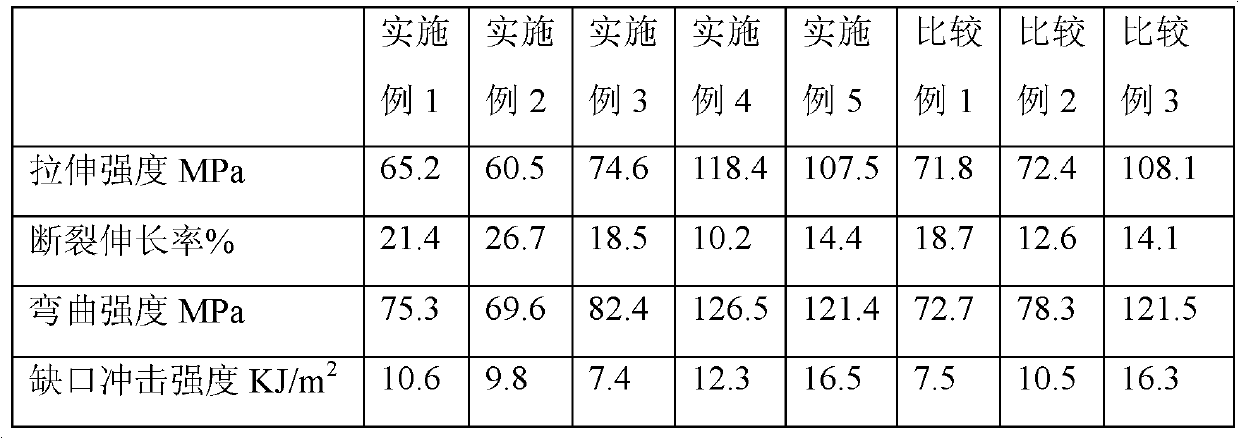

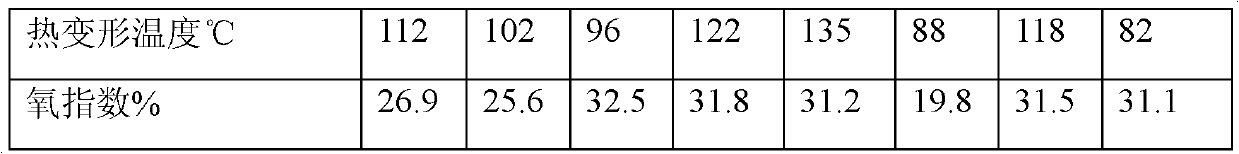

Examples

Embodiment 1

[0045] According to the proportion of the formula, 100 parts of ABS (acrylonitrile-butadiene-styrene copolymer), 32 parts of alkali-free glass fiber (treated by methacrylic acid propyl trimethoxysilane), 5 parts of ethylene methyl acrylate carbonyl copolymer Parts, 12 parts of melamine cyanurate, 3 parts of zinc borate, 1.5 parts of [β-(3,5 di-tert-butyl 4-hydroxy-phenyl)propionic acid] pentaerythritol ester, tris(1,2,2 phosphite , 12 parts of 6,6-pentamethylpiperidine) ester, 15 parts of polymethacrylimide, 5 parts of epoxy resin, and 0.8 part of zinc stearate were added to the high-speed mixer at a speed of 1000r / min, and mixed Discharge after 2~5 minutes;

[0046] Put the mixed material in a twin-screw extruder to melt, mix, extrude and granulate. The segmental temperature of the screw extruder is 180-190°C, 195-205°C, 210-220°C, 200-210°C, and the screw speed is 280r / min;

[0047] Then the obtained pellets are injection molded, the barrel temperature is 190-200° C., the ...

Embodiment 2

[0049] According to the formula ratio, 100 parts of ABS (acrylonitrile-butadiene-styrene copolymer), 35 parts of carbon fiber, 3 parts of ethylene-vinyl acetate copolymer, 10 parts of melamine phosphate, 4 parts of antimony trioxide, N, N 1.8 parts of '-di(β-naphthyl)-p-phenylenediamine, 1.0 parts of 2-hydroxy-4-methoxybenzophenone, 12 parts of polymethacrylimide, 5 parts of styrene-grafted maleic anhydride Parts, 0.5 parts of zinc stearate are added to the high-speed mixer, the speed is 920r / min, and the material is discharged after mixing for 2 to 5 minutes;

[0050] Put the mixed material in a twin-screw extruder to melt, mix, extrude and granulate. The segmental temperature of the screw extruder is 180-190°C, 195-205°C, 210-220°C, 200-210°C, and the screw speed is 300r / min;

[0051]The obtained pellets are then injection molded, the barrel temperature is 190-200° C., the nozzle temperature is 195-205° C., the injection pressure is 72 MPa, and the holding pressure is 32 MP...

Embodiment 3

[0053] According to the formula ratio, 100 parts of ABS (acrylonitrile-butadiene-styrene copolymer), 25 parts of asbestos fiber, 20 parts of melamine borate, 6 parts of antimony trioxide, [β-(3,5 di-tert-butyl Base 4-hydroxy-phenyl)propionic acid]pentaerythritol ester 1.5 parts, 2-hydroxy-4-methoxybenzophenone 1.5 parts, N-phenyl grafted maleimide 10 parts, epoxy resin 2 2 parts, 2 parts of styrene-grafted maleic anhydride, 1.0 parts of N, N'-ethylene bis-stearic acid amine were added to the high-speed mixer at a speed of 800r / min, mixed for 2 to 5 minutes and then discharged;

[0054] Put the mixed material in a twin-screw extruder to melt, mix, extrude and granulate. The segmental temperature of the screw extruder is 180-190°C, 195-205°C, 210-220°C, 200-210°C, and the screw speed is 200r / min;

[0055] Then the obtained pellets are injection molded, the barrel temperature is 190-200° C., the nozzle temperature is 195-205° C., the injection pressure is 65 MPa, and the holding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com