Platable polycarbonate/acrylonitrile-butadiene-styrene alloy material with high heat resistance and impact resistance

A technology of alloy materials and raw materials, which is applied in the field of PC/ABS polymer alloy materials with high heat resistance and high impact resistance and can be electroplated. It can solve the problems of poor electroplating performance, difficult electroplating, and increased surface adhesion to achieve heat resistance. And the effect of good processing formability, high yield of electroplating, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific examples, but not limited to these examples.

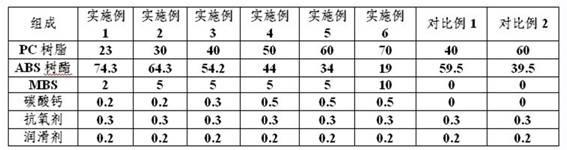

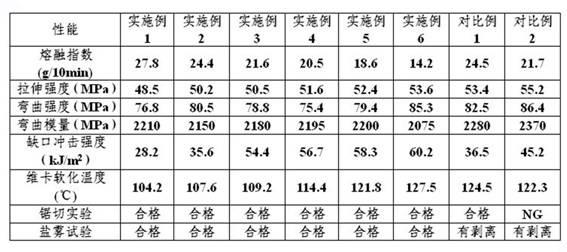

[0030] The formula of each embodiment and comparative example is listed in Table 1;

[0031] Selected in the formula of each embodiment and comparative example:

[0032] Polycarbonate is selected from a kind of linear PC derived from bisphenol A and phosgene produced and sold by U.S. Dow Chemical Company, and its brand is 300-10;

[0033] The styrene-butadiene-acrylonitrile copolymer is selected from the ABS produced and sold by the emulsion polymerization method of BASF, Germany, and its brand name is GP-22;

[0034] The butadiene-based graft rubber is selected from the methacrylate-butadiene-styrene copolymer (MBS) produced and sold by Korea LG Chemical Company, its brand M-521, which is a core-shell structure Toughener, which mainly provides toughness for the material;

[0035] Inorganic filler CaCO 3 , provided by Wuhu We...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com