Gas sensor based on nanometer line array and its prepn process

A technology of gas sensor and nanowire array, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of difficult mass production and low production efficiency, and achieve the effect of high sensitivity and convenient industrial mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

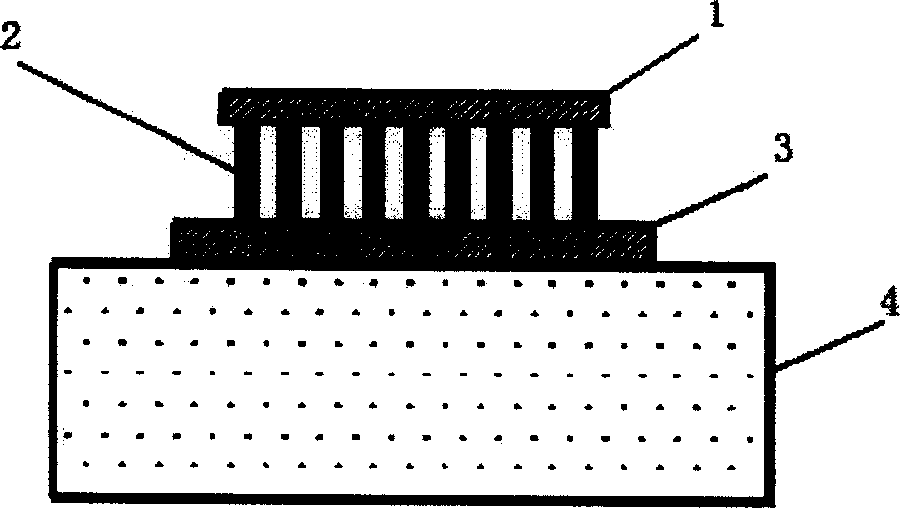

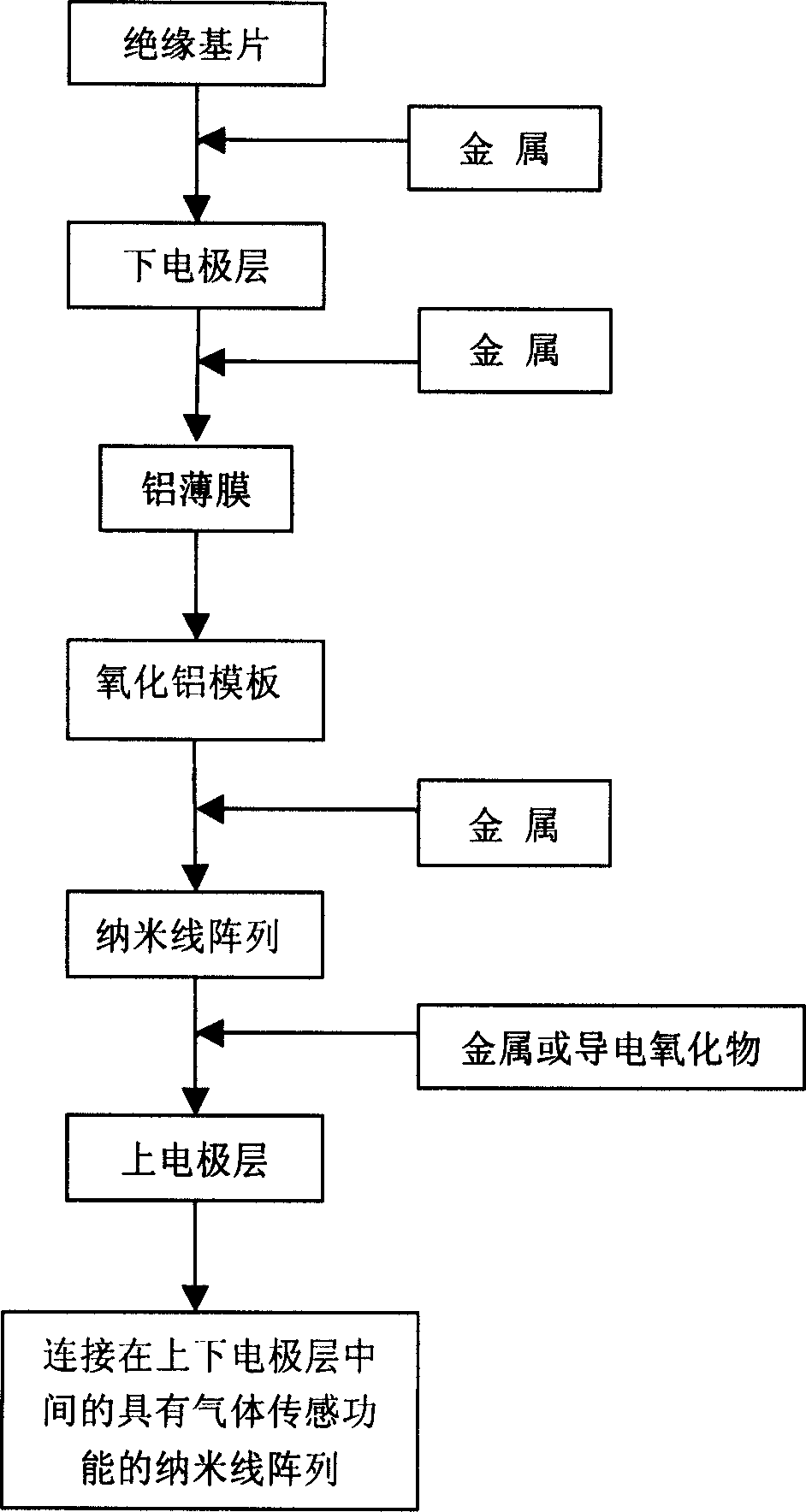

[0029] Including an insulating substrate (4); a lower electrode layer (3) arranged on the insulating substrate; a sensing conductor (2) nanowire array connected to the lower electrode layer (3); an upper end connected to the upper end of the nanowire array Electrode layer (1). Wherein: the insulating substrate is quartz; the material of the lower electrode layer is silver thin film, the nano wire is tin oxide nano wire, and the material of the upper electrode layer is silver thin film.

[0030] 1. Preparation of the lower electrode layer

[0031] A silver film is deposited on a quartz substrate by magnetron sputtering, the thickness of the film is 90-100 nanometers, the target material of sputtering is silver, the sputtering power is 100 watts, and the sputtering pressure is 0.9 Pa.

[0032] 2. Preparation of porous alumina template

[0033] Utilize magnetron sputtering to deposit metal aluminum on the surface that is deposited with silver film to form aluminum film, the thi...

Embodiment 2

[0041] Including an insulating substrate (4); a lower electrode layer (3) arranged on the insulating substrate; a sensing conductor (2) nanowire array connected to the lower electrode layer (3); and an upper end of the nanowire array (2) connected to the upper electrode layer (1). Wherein: the insulating substrate is quartz; the material of the lower electrode layer is silver film, the nanowire is copper oxide nanowire, and the material of the upper electrode layer is tin-doped indium oxide.

[0042] 1. Preparation of the lower electrode layer

[0043] A silver film is deposited on a quartz substrate by magnetron sputtering, the thickness of the film is about 100-115 nm, the target material of the sputtering is silver, the sputtering power is 100 watts, and the sputtering pressure is 0.9 Pa.

[0044] 2. Preparation of porous alumina template

[0045] Magnetron sputtering is used to deposit an aluminum film on the silver film. The thickness of the aluminum film is 10 microns....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com