Air gap breakdown voltage prediction method

A technology of breakdown voltage and air gap, which is applied in the direction of testing dielectric strength, etc., can solve problems such as the uncertainty of numerical solution algorithms and the deviation of test measurement results, and achieve the effects of reducing test volume, high accuracy, and simple prediction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

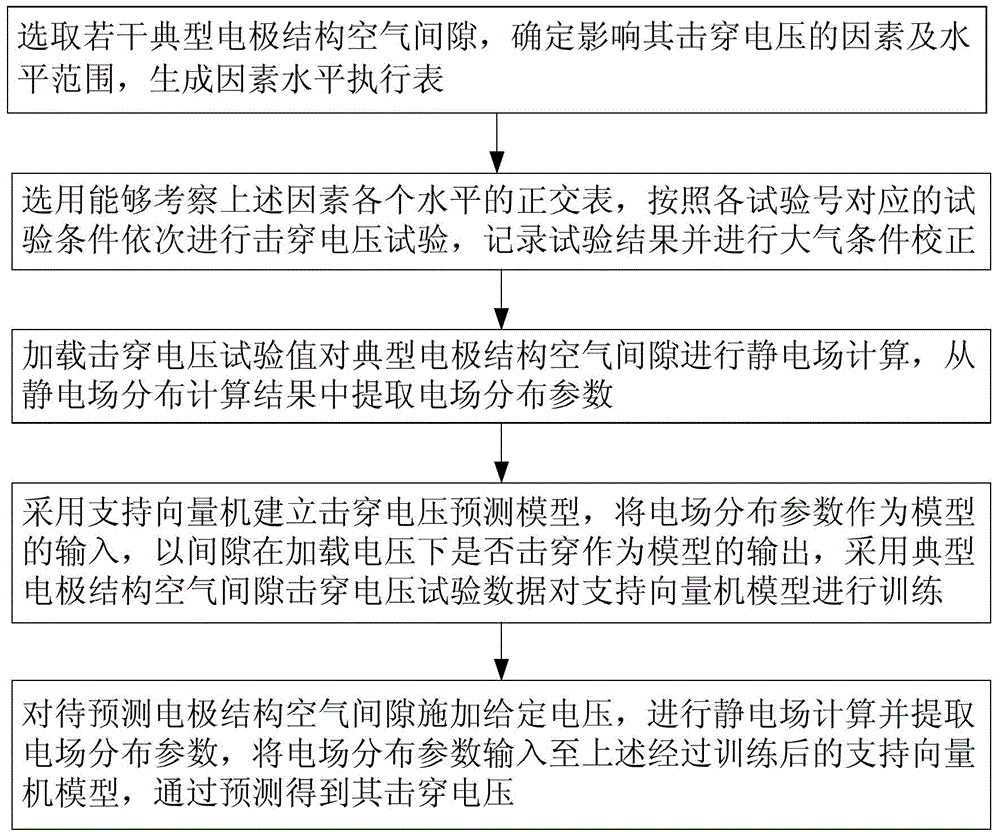

[0018] figure 1 Shown is a schematic flow chart of the air gap breakdown voltage prediction method according to an embodiment of the present invention, and the present invention includes the following steps:

[0019] Step 1: Select some typical electrode structure air gaps, determine the factors affecting their breakdown voltage, select the horizontal range for each influencing factor, and generate a factor level execution table.

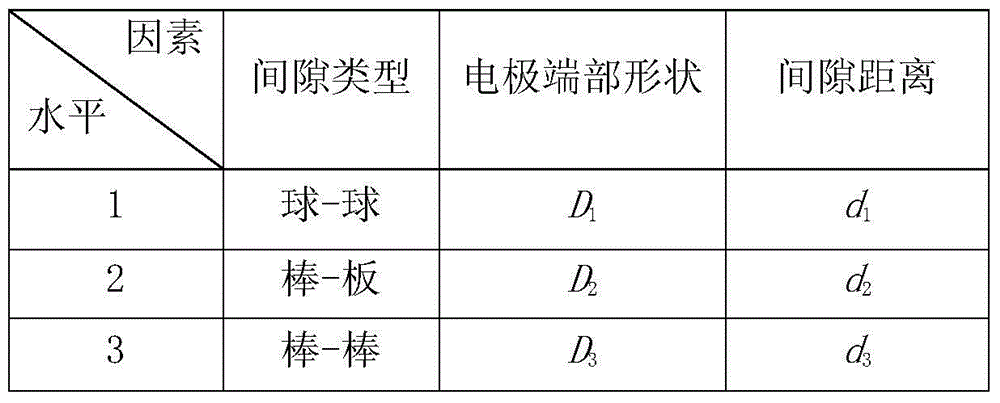

[0020] In this example, three typical electrode structure air gaps are selected: ball-ball, rod-plate, and rod-rod. The factors affecting the breakdown voltage include gap type, electrode end shape, and gap distance. The three levels of the gap type refer to three electrode structures of ball-ball, rod-plate, and rod-rod; the three levels of electrode end shape refer to three kinds of ball diameters for the ball-ball gap. In this embodiment, 6.25cm is selected. , 10cm and 15cm, for rod-plate gap and rod-rod gap, refer to 3 kinds of rod electrode en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com