Method for separating nickel and cobalt from manganese in high manganese-cobalt ratio nickel-cobalt-manganese raw material

A technology of nickel-cobalt-manganese and high-manganese, applied in the direction of improving process efficiency, etc., can solve the problems of unqualified battery materials of nickel-cobalt sulfate solution, difficulty in separating nickel-cobalt and manganese, and achieve low production costs, fewer types of impurities, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

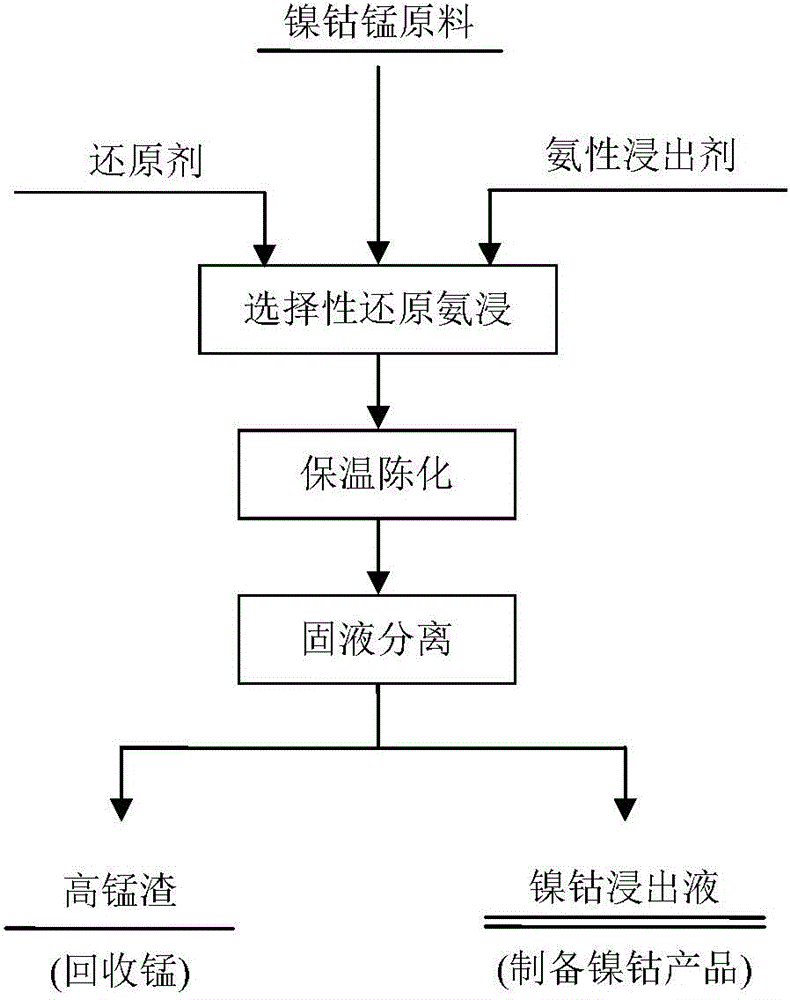

[0034] a kind of like figure 1 The method for separating nickel-cobalt and manganese in the high-manganese-cobalt ratio nickel-cobalt-manganese raw material of the present invention comprises the following steps:

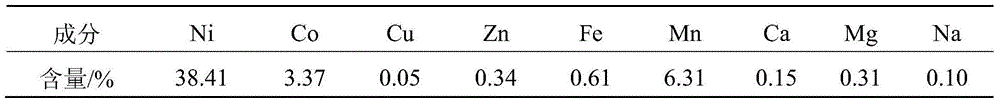

[0035] (1) The primary product of nickel extraction produced by a nickel smelter in Africa is a high-manganese-cobalt-ratio nickel-cobalt-manganese raw material. The primary product of nickel extraction is obtained from laterite nickel ore after pressure acid leaching and alkaline precipitation. The composition includes nickel hydroxide and cobalt precipitation slag, and the determination of the main element content is shown in Table 1 below. The moisture content in the raw material is 62.41%, and the mass ratio of manganese and cobalt elements is 1.87.

[0036] Table 1: Analysis of the main chemical elements of the nickel primary product in Example 1

[0037]

[0038] (2) The high manganese-cobalt ratio nickel-cobalt-manganese raw material of the above-mentione...

Embodiment 2

[0041] a kind of like figure 1 The method for separating nickel-cobalt and manganese in the high-manganese-cobalt ratio nickel-cobalt-manganese raw material of the present invention comprises the following steps:

[0042] (1) the high manganese cobalt ratio nickel cobalt manganese raw material that present embodiment selects is identical with embodiment 1;

[0043] (2) The high manganese-cobalt ratio nickel-cobalt-manganese raw material of the present embodiment is mixed with the ammonia leaching agent, and the ammonia leaching agent adopted in the present embodiment is NH 3 ·H 2 O-(NH 4 ) 2 SO 4 Mixed leaching system, initial ammonia concentration [NH 3 ] T Controlled to 140g·L -1 , the liquid-solid ratio during leaching is (ml·g -1 ) 12:1, stirring and leaching at room temperature for 2 hours and then slowly adding hydroxylamine sulfate as a reducing agent, the addition of hydroxylamine sulfate is 2 times the content of cobalt in the high manganese-cobalt ratio nicke...

Embodiment 3

[0046] a kind of like figure 1 The method for separating nickel-cobalt and manganese in the high-manganese-cobalt ratio nickel-cobalt-manganese raw material of the present invention comprises the following steps:

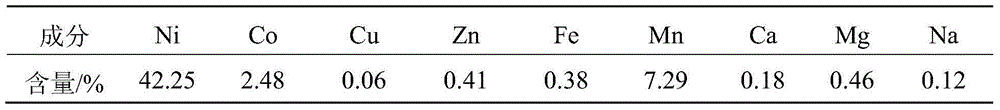

[0047] (1) The primary product of nickel extraction produced by a battery material factory in Hunan is a high-manganese-cobalt ratio nickel-cobalt-manganese raw material. The primary product of nickel extraction is obtained from laterite nickel ore after pressurized acid leaching and alkaline precipitation. The composition includes nickel hydroxide cobalt precipitated slag, the determination of the main element content is shown in Table 2 below, wherein the moisture content in the raw material is 48.29%, and the mass ratio of manganese and cobalt elements is 2.94;

[0048] Table 2: Analysis of the main chemical elements of the nickel primary product in Example 3

[0049]

[0050] (2) The high manganese-cobalt ratio nickel-cobalt-manganese raw material of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com