Inorganic-organic salt-resisting and high temperature-resisting polymer fluid loss additive for drilling fluid

A fluid loss control agent, polymer technology, used in drilling compositions, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following specific examples are used to further optimize the synthesis method of the present invention

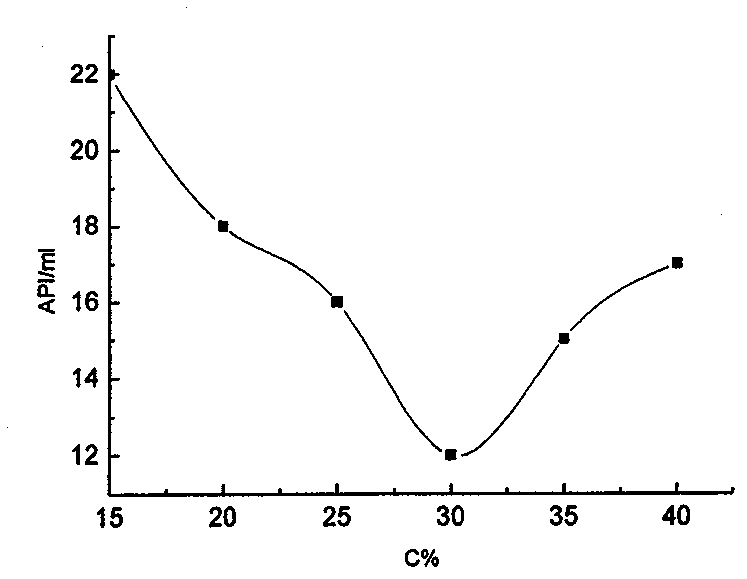

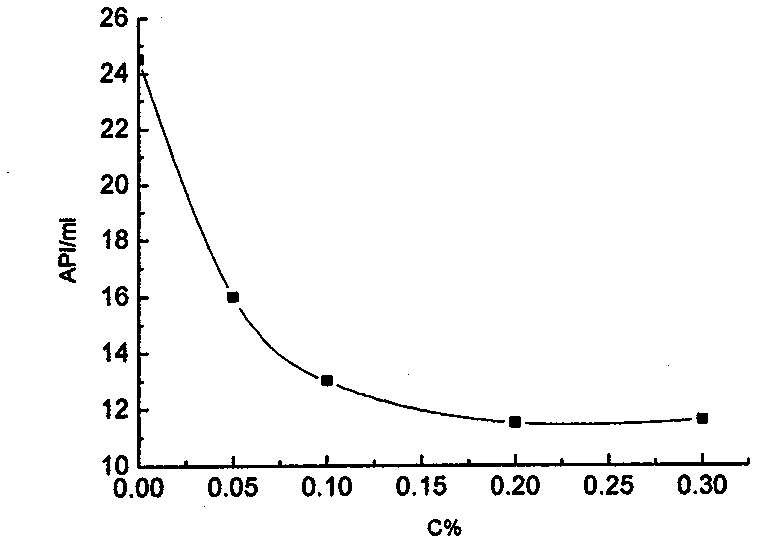

[0010] The purpose of this research is to find out the influence of various reaction factors on the properties of the polymerized product, and finally to get the best synthesis scheme. Here, the fluid loss reduction effect of the product in the composite brine base slurry is selected as the basis for optimizing the synthesis conditions, and the sample addition is 1%.

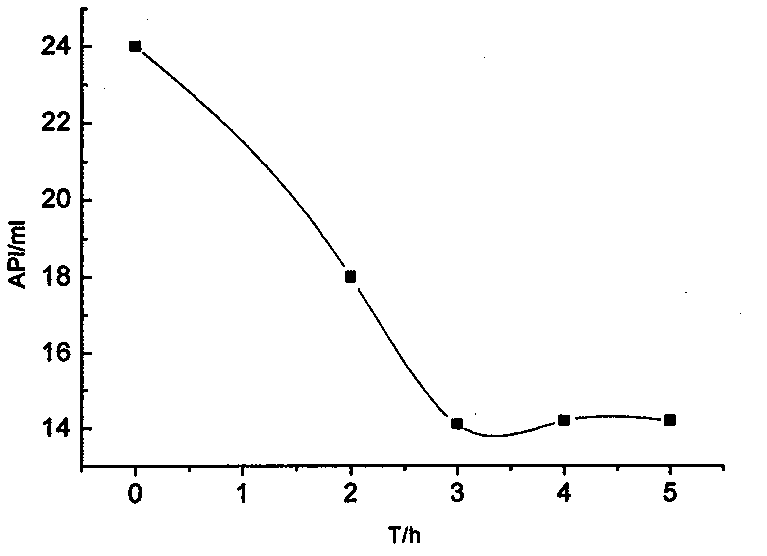

[0011] The choice of reaction time

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com