Temperature-resistant calcium-tolerant inverse emulsion polymer for drilling fluids and preparation method

A technology of inverse emulsion and drilling fluid, which is applied in the direction of drilling composition, chemical instruments and methods, etc., to achieve the effect of good effect, good stability and improvement of filter cake quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

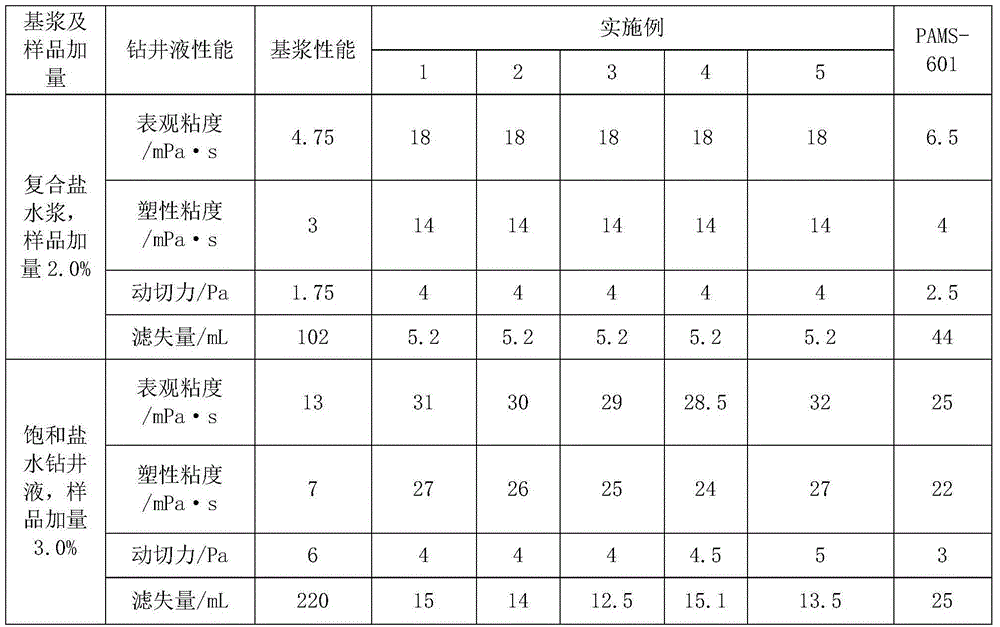

Examples

Embodiment 1

[0022] Add 100kg of water to the reactor, start stirring, add 200kg of sodium 2-acrylamido-2-methylpropanesulfonate aqueous solution with a mass fraction of 50%, 10kg of N,N-dimethylacrylamide, 80kg of acrylamide, 0.015 kg ethylene dimethacrylate, 0.015 kg ethylene diamine tetraacetic acid disodium salt, 1.5 kg OP-15, 5 kg soda ash, stir until fully dissolved, control the pH of the system to 8.0, and obtain the aqueous phase required for the emulsion; Add 140kg of white oil, 10kg of Span-80 and 10kg of propylene glycol monolaurate emulsifier to the reaction kettle, and stir until all dissolved to obtain the required oil phase; the obtained water phase is slowly added to the oil phase under stirring, Then fully stir in the emulsification kettle for 20 minutes to obtain the monomer compound inverse emulsion; put the obtained emulsion into the reaction kettle, turn on the stirrer, heat up to 50°C, vent nitrogen for 15 minutes, and add 1kg 10% mass fraction of initiator persulfuric ...

Embodiment 2

[0024] Add 150kg of water to the reactor, start stirring, add 140kg of sodium 2-acryloxy-2-methylpropanesulfonate with a mass fraction of 50%, 20kg of N,N-dimethylacrylamide, and 130kg of acrylamide. 0.005kg ethylene diacrylate, 0.005kg ethylenediaminetetraacetic acid disodium salt, 5kg OP-15, 1kg soda ash, stir until all dissolved, control the pH of the system to 7.5, and obtain the aqueous phase required for the emulsion; in the reactor Add 180kg of white oil, 15kg of Span-80 and 5kg of propylene glycol monolaurate emulsifier, stir until completely dissolved to obtain the required oil phase; the resulting water phase is slowly added to the oil phase under stirring, and then Fully stir in the emulsification kettle for 20 minutes to obtain the monomer compound inverse emulsion; put the obtained emulsion into the reaction kettle, turn on the mixer, heat up to 50°C, vent nitrogen for 15 minutes, and add 4 kg of 10% by weight initiator potassium persulfate aqueous solution , 4kg o...

Embodiment 3

[0026] Add 120kg of water to the reactor, start stirring, add 180kg of sodium 2-acrylamido-2-methylpropanesulfonate with a mass fraction of 50%, 40kg of N,N-dimethylacrylamide, 90kg of acrylamide, 0.01 kg ethylene dimethacrylate, 0.01 kg ethylene diamine tetraacetic acid disodium salt, 3 kg OP-15, 3 kg soda ash, stir until fully dissolved, control the pH of the system to 8.0, and obtain the aqueous phase required for the emulsion; Add 160kg of white oil, 13kg of Span-80 and 8kg of propylene glycol monolaurate emulsifier to the kettle, stir until completely dissolved to obtain the required oil phase; the obtained water phase is slowly added to the oil phase under stirring, and then Fully stir in the emulsification kettle for 20 minutes to obtain the monomer compound inverse emulsion; put the obtained emulsion into the reaction kettle, turn on the stirrer, heat up to 50°C, blow nitrogen for 15 minutes, and add 1.5 kg of 10% mass fraction of initiator persulfuric acid Ammonium aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com