Lubricity improver for low-sulfur and low-freezing-point diesel oil

A low-sulfur diesel oil and lubricity technology, applied in the field of chemical product preparation, can solve the problems of reducing the oxidation stability of diesel oil, carbon deposits in fuel nozzles, and affecting the quality of diesel oil, so as to improve the lubricity of low-sulfur diesel oil and reduce friction and wear , the effect of adding a small amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A novel low-sulfur low-condensation-point diesel oil lubricity improver consists of 85% long-chain unsaturated fatty acid, 10% polyisobutylene succinic anhydride and 5% sorbitan fatty acid monoester (dispersed agent) composition. The long-chain unsaturated fatty acid is composed of 55% linoleic acid, 32% soybean oleic acid and 13% linolenic acid according to the mass percentage, polyisobutylene succinic anhydride is composed of T2007A, sorbitan fatty acid monosodium Esters are glycerides.

[0021] The preparation method of the low-sulfur low-condensation-point diesel oil lubricity improver is as follows: first, linoleic acid, soybean oleic acid, and linolenic acid are mixed in proportion to obtain long-chain unsaturated fatty acids; then long-chain unsaturated fatty acids, T2007A and Glycerides were added into the mixing tank in proportion, heated to 40°C, stirred thoroughly for 20 minutes, and then filtered with a 70-mesh stainless steel filter to obtain the finished ...

Embodiment 2

[0028] A novel low-sulfur low-condensation-point diesel oil lubricity improver consists of 90% long-chain unsaturated fatty acid, 5% polyisobutylene succinic anhydride and 5% sorbitan fatty acid monoester (dispersed agent) composition. The long-chain unsaturated fatty acid is composed of 55% linoleic acid, 32% soybean oleic acid and 13% linolenic acid according to the mass percentage, polyisobutylene succinic anhydride is composed of T2007A, sorbitan fatty acid monosodium Esters are glycerides.

[0029] The preparation method of the low-sulfur low-condensation-point diesel lubricity improver is the same as that in Example 1.

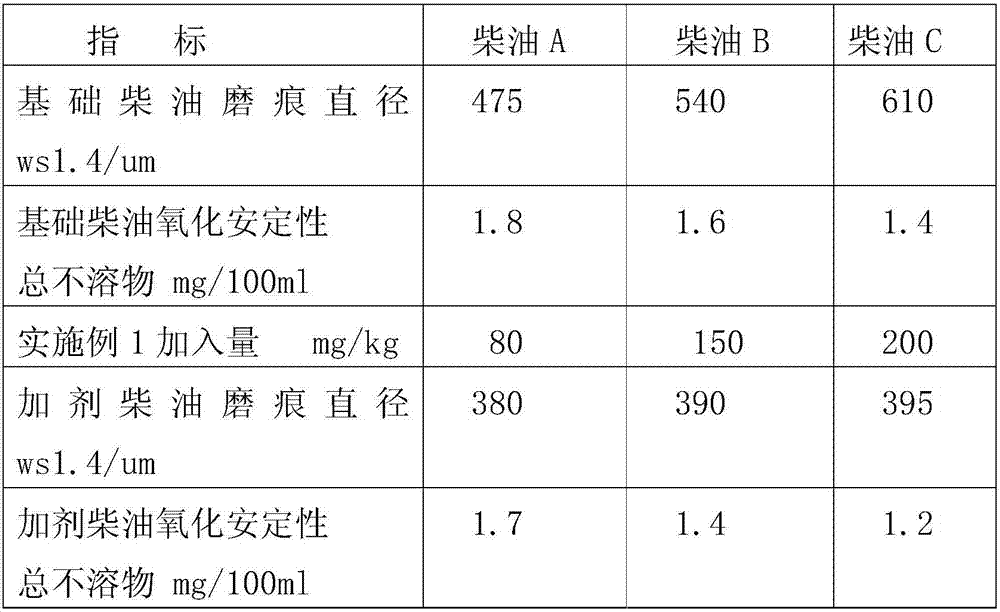

[0030] Comparative Test

[0031] Three kinds of diesel oils with different lubricating properties were added with different doses of the diesel lubricity improver given in Example 2 of the present invention, and the wear scar diameter and the total insoluble matter of diesel oxidation stability were tested. The specific results are shown in Table 2 bel...

Embodiment 3

[0036] A novel low-sulfur low-condensation-point diesel oil lubricity improver consists of 93% long-chain unsaturated fatty acid, 5% polyisobutylene succinic anhydride and 2% sorbitan fatty acid monoester (dispersed agent) composition. The long-chain unsaturated fatty acid is composed of 55% linoleic acid, 32% soybean oleic acid and 13% linolenic acid according to the mass percentage, polyisobutylene succinic anhydride is composed of T2007A, sorbitan fatty acid monosodium Esters are glycerides.

[0037] The preparation method of the low-sulfur low-condensation-point diesel lubricity improver is the same as that in Example 1.

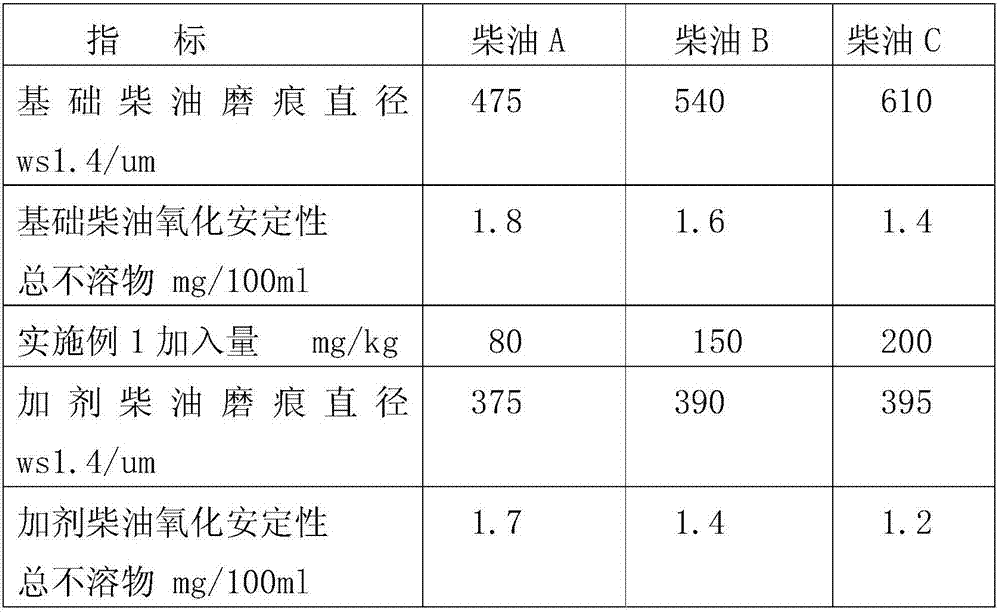

[0038] Comparative Test

[0039] Three kinds of diesel oils with different lubricating properties were added with different doses of the diesel oil lubricity improver given in Example 3 of the present invention, and the wear scar diameter and the total insoluble matter of diesel oxidation stability were tested. The specific results are shown in Table 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com