A preparation method of acid-resistant thickener and its application in multifunctional acid and acid-resistant fracturing fluid

A technology of thickener and solubilizer, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of complex on-site operation, poor compatibility between acid liquid and fracturing fluid, and various types of additions, etc., to achieve controllable Strong performance, easy on-site operation, fast dispersion and dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention also provides a preparation method for the above-mentioned acid-resistant thickener, comprising: dissolving acrylamide, cationic hydrophobic monomer, anionic monomer and solubilizer in water in proportion, adjusting the pH to 6.5-7.5 with sodium hydroxide, mixing The solution is heated to 10-40°C, and the initiator is added under the condition of blowing nitrogen to remove oxygen, and the polymerization reaction is carried out for 4-6 hours, and then granulated, and dried at 90-100°C for pulverization. Wherein, before adding the initiator, nitrogen gas is used to remove oxygen for 15-25 minutes.

[0024] The synthetic method of cationic hydrophobic monomer methacryloyloxyethyl dimethyl dodecyl ammonium bromide comprises: weighing dimethylaminoethyl methacrylate (DM ) and dodecane bromide in a reactor, add an appropriate amount of acetone, stir evenly, and react in a closed manner at room temperature (15-30° C.) for 45-50 hours. Then crystallize in...

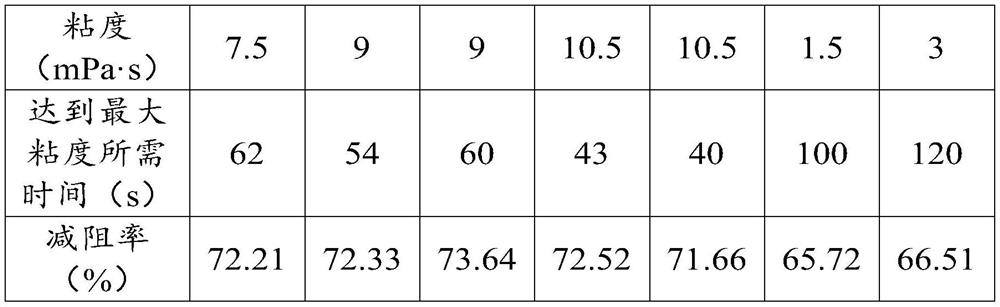

Embodiment 1

[0035] This embodiment provides an acid-resistant thickener, which is mainly prepared through the following steps:

[0036] By weight percentage, take acrylamide 10%, methacryloxyethyl dimethyl dodecyl ammonium bromide 0.3%, methacrylic acid 20%, solubilizer TX-10 0.3%, initiator ammonium persulfate 0.06% and the balance water.

[0037]Dissolve acrylamide, methacryloyloxyethyl dimethyl dodecyl ammonium bromide, methacrylic acid and solubilizer TX-10 in water, adjust the pH to 7 with sodium hydroxide, and keep the mixed solution warm to 10 ℃, after blowing nitrogen to remove oxygen, add initiator ammonium persulfate to carry out polymerization reaction for 4 hours, then carry out granulation, and dry and pulverize at 100 ℃.

Embodiment 2

[0039] This embodiment provides an acid-resistant thickener, which is mainly prepared through the following steps:

[0040] By weight percentage, take acrylamide 20%, methacryloxyethyl dimethyl dodecyl ammonium bromide 0.5%, methacrylic acid 15%, solubilizer TX-10 0.35%, initiator potassium persulfate 0.1% and the balance water.

[0041] Dissolve acrylamide, methacryloyloxyethyl dimethyl dodecyl ammonium bromide, methacrylic acid and solubilizer TX-10 in water, adjust the pH to 7.5 with sodium hydroxide, and heat the mixed solution to 40 ℃, after blowing nitrogen to remove oxygen, add initiator potassium persulfate to carry out polymerization reaction for 4 hours, then carry out granulation, and dry and pulverize at 90 ℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com