Waterproof grease and hermetically filled with the grease, rolling bearing and hub bearing

A grease, non-aqueous technology, used in the field of rolling bearings and wheel hub bearings, to achieve the effect of inhibiting surface starting point peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and Embodiment 2

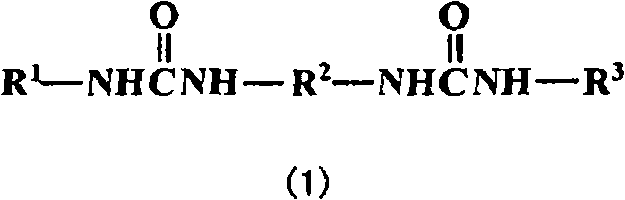

[0122] A mineral oil / urea base grease (JIS consistency No. 2 grade, consistency: 265 to 295) obtained by uniformly dispersing a urea compound as a thickener in mineral oil as a non-aqueous base oil was prepared.

[0123] Kinematic viscosity at 2000g of mineral oil (TAIBIN 100 manufactured by Nippon Oil Corporation, at 40°C): 100mm 2 / sec), 231.7 g of diphenylmethane-4,4'-diisocyanate, 86.2 g of aniline, and 91.7 g of cyclohexylamine were reacted to uniformly disperse the generated urea compound to obtain a base grease. Additives were blended to this base grease in the blends shown in Table 1 to obtain test greases.

[0124] The obtained test grease was subjected to an oil film formation rate test 1 and a water dispersion confirmation test shown below, and the oil film formation rate, the mixing method with water, and the water particle size were measured. The results are summarized in Table 1.

[0125]

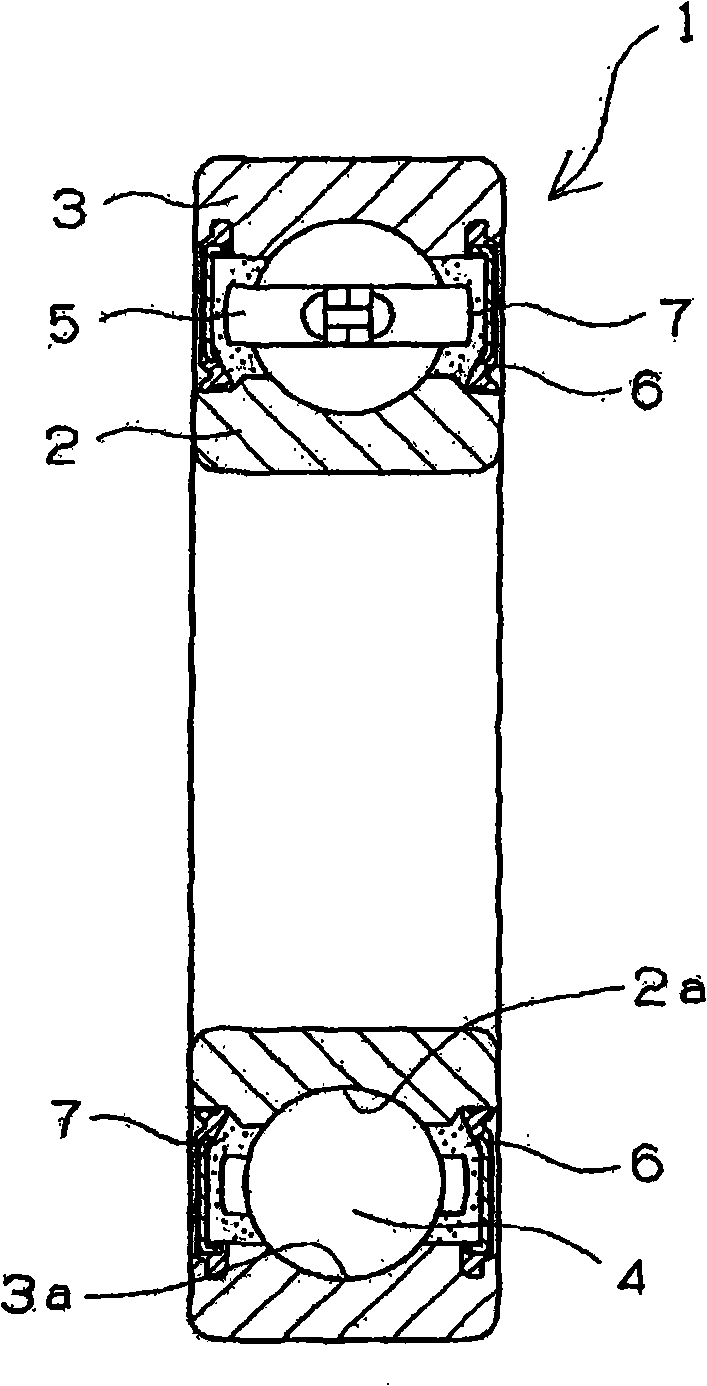

[0126] Bearings used: The angular contact ball bearing 7006ADLLB is s...

Embodiment 3 and comparative example 1~ comparative example 2

[0132] A mineral oil / urea base grease (JIS consistency No. 2 grade, consistency: 265 to 295) obtained by uniformly dispersing a urea compound as a thickener in mineral oil as a base oil was prepared.

[0133] Kinematic viscosity at 2000g of mineral oil (Nippon Oil Co., Ltd.'s Super C, 40°C): 100mm 2 / sec), 234.8 g of diphenylmethane-4,4'-diisocyanate and 174.8 g of aniline were reacted to uniformly disperse the generated urea compound to obtain a base grease. Additives were blended to this base grease in the blends shown in Table 1 to obtain hub bearing grease.

[0134] The obtained grease for hub bearings was evaluated in the same manner as in Example 1. The results are summarized in Table 1.

[0135] [Table 1]

[0136]

[0137] 1) Kinematic viscosity at 40°C of Tabin 100 manufactured by Nippon Oil Corporation: 100mm 2 / Second

[0138] 2) Aniline

[0139] 3) Cyclohexylamine

[0140] 4) スルホール CA-45 manufactured by Matsumura Petroleum Co., Ltd.

[0141] 5) Reagents man...

Embodiment 4~ Embodiment 14

[0146] Embodiment 4~Example 14 and Comparative Example 3~Comparative Example 8

[0147] A mineral oil / urea base grease (JIS consistency No. 2 grade, consistency: 265 to 295) obtained by uniformly dispersing a urea compound as a thickener in mineral oil as a non-aqueous base oil was prepared.

[0148] Kinematic viscosity at 2000g of mineral oil (TAIBIN 100 manufactured by Nippon Oil Corporation, at 40°C): 100mm 2 / sec), 231.7 g of diphenylmethane-4,4'-diisocyanate, 86.2 g of aniline, and 91.7 g of cyclohexylamine were reacted to uniformly disperse the generated urea compound to obtain a base grease. Additives were blended into this base grease in the blends shown in Tables 2 and 3 to obtain test greases.

[0149] The obtained test grease was supplied to the following oil film formation rate test 2, bearing life test, and saturated water content measurement, and the oil film formation rate, bearing life time, saturated water content, and the presence or absence of rust were mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com