Stator for axial clearance type motor and axial clearance type motor

An axial gap and motor technology, applied in the field of electric motors, can solve the problems of increased cost, structural obstacles to the increase of maximum power, and inability to effectively improve the specific power of axial gap motors, so as to achieve the improvement of specific power and maximum power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

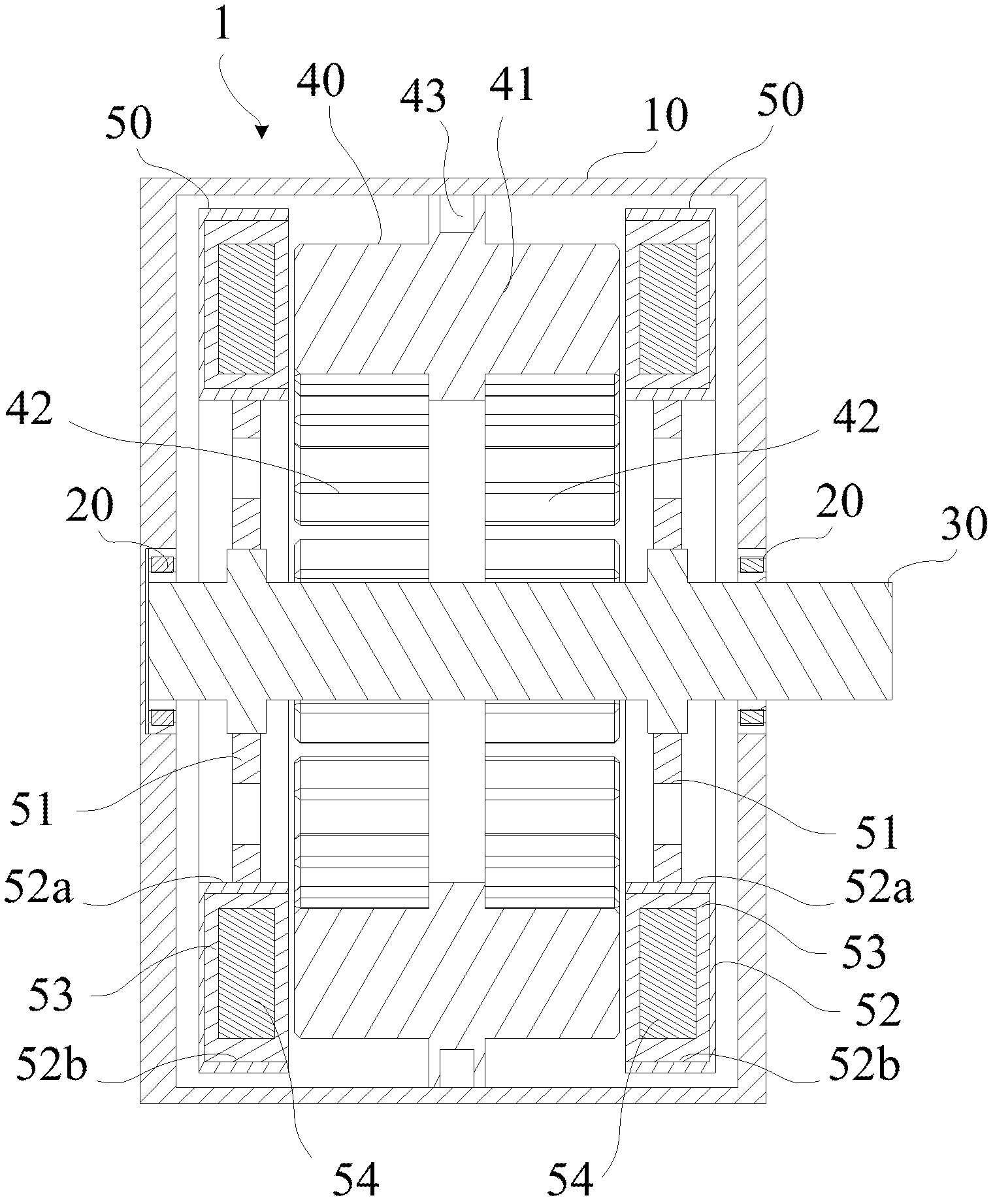

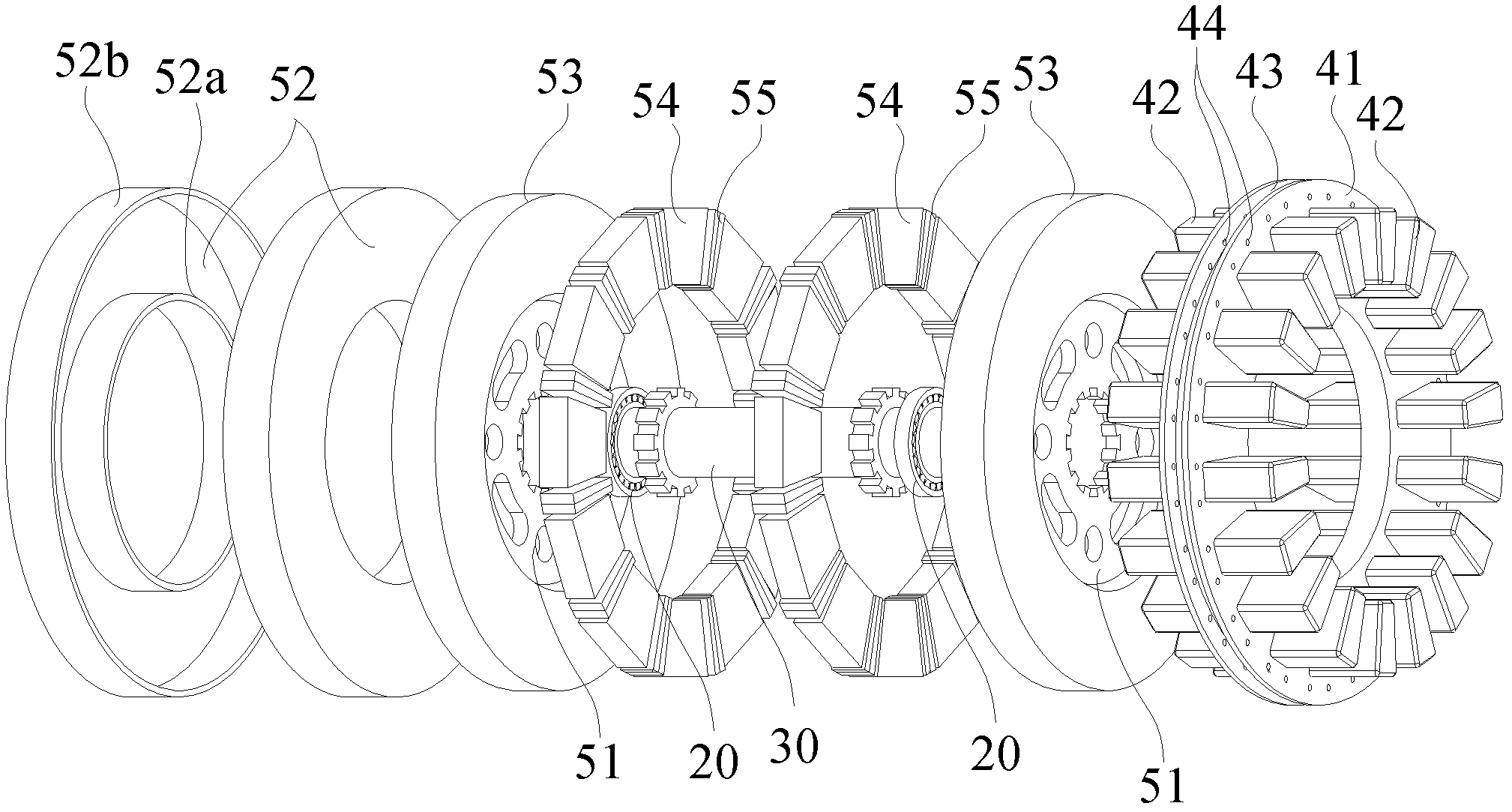

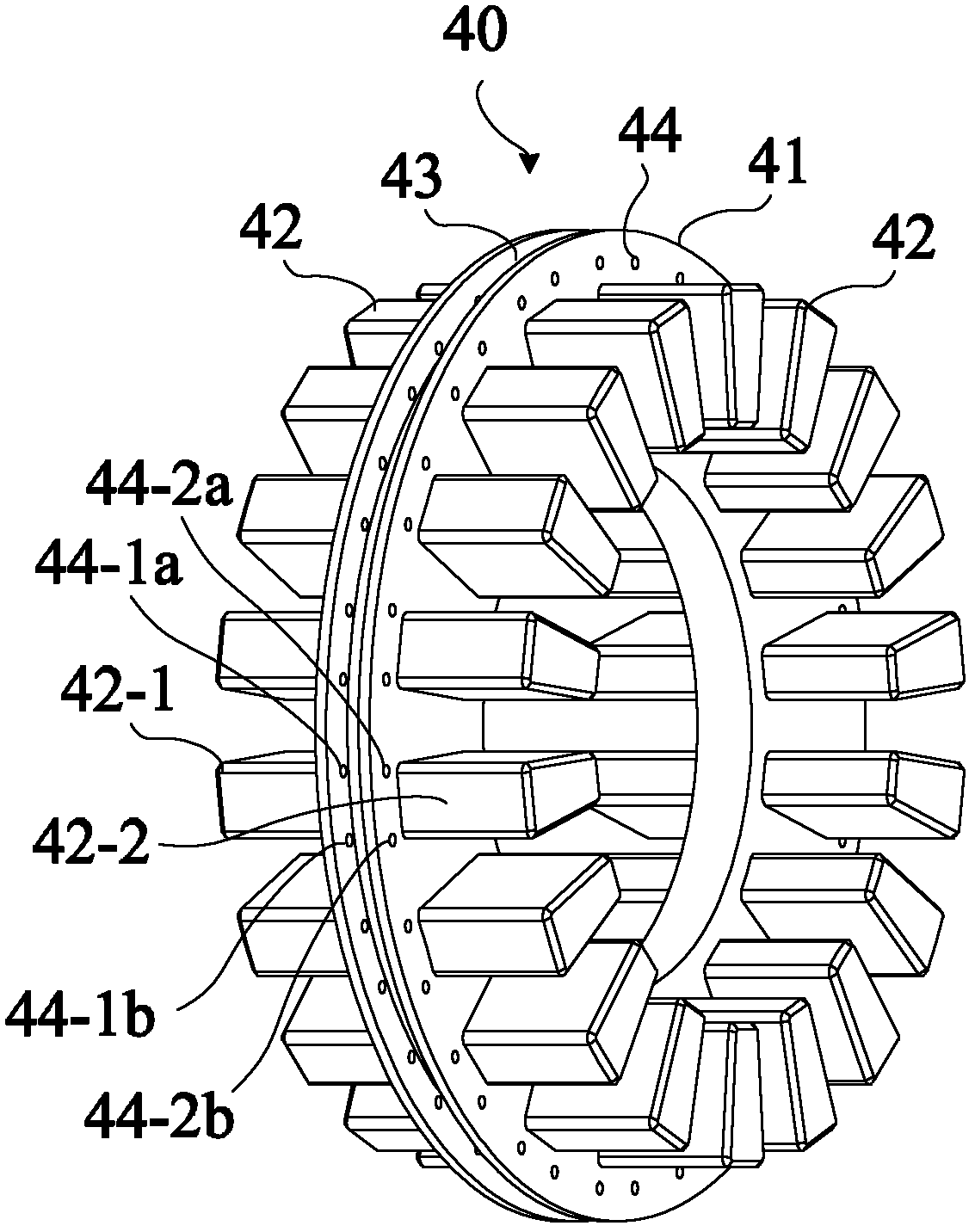

[0036] figure 1 It is an assembly sectional view of the axial gap motor in the specific embodiment of the present invention. figure 2 It is an exploded schematic diagram of an axial gap motor in a specific embodiment of the present invention.

[0037] See figure 1 and figure 2 , the axial gap motor 1 in the specific embodiment of the present invention includes: a housing 10 (not in figure 2 Shown in), two bearings 20, a rotating shaft 30, a stator 40, two rotors 50. in:

[0038] The shell 10 has two opposite end faces and a closed surrounding peripheral face;

[0039] The two bearings 20 are respectively arranged on the two end surfaces of the housing 10;

[0040] The rotating shaft 30 is carried by two bearings 20;

[0041] The stator 40 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com