Stepping motor control-based high-power electronic switch

A technology of stepping motors and electronic switches, applied to electric switches, power devices inside switches, circuits, etc., can solve problems such as high requirements for protection boxes, disconnected circuits, and small driving force, so as to improve electrical conductivity and prolong service life The effect of life and power improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

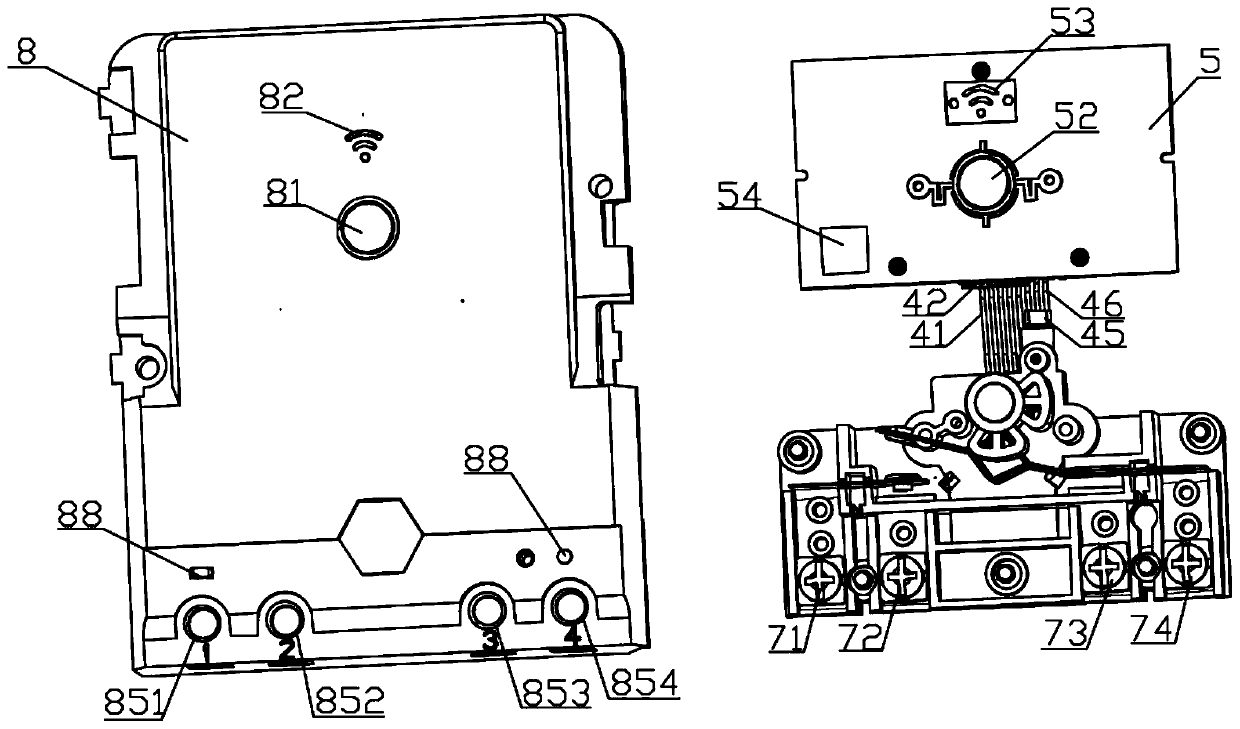

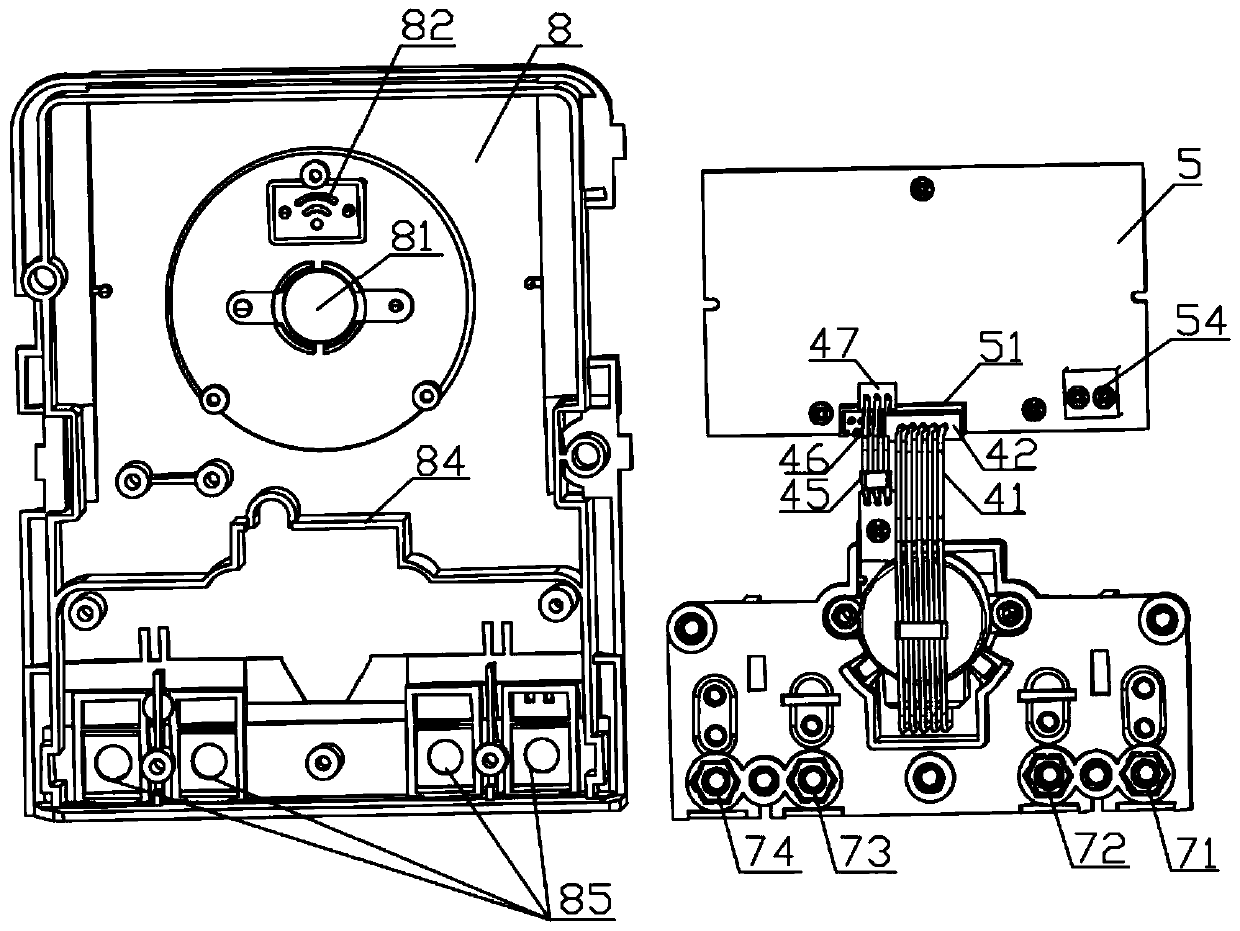

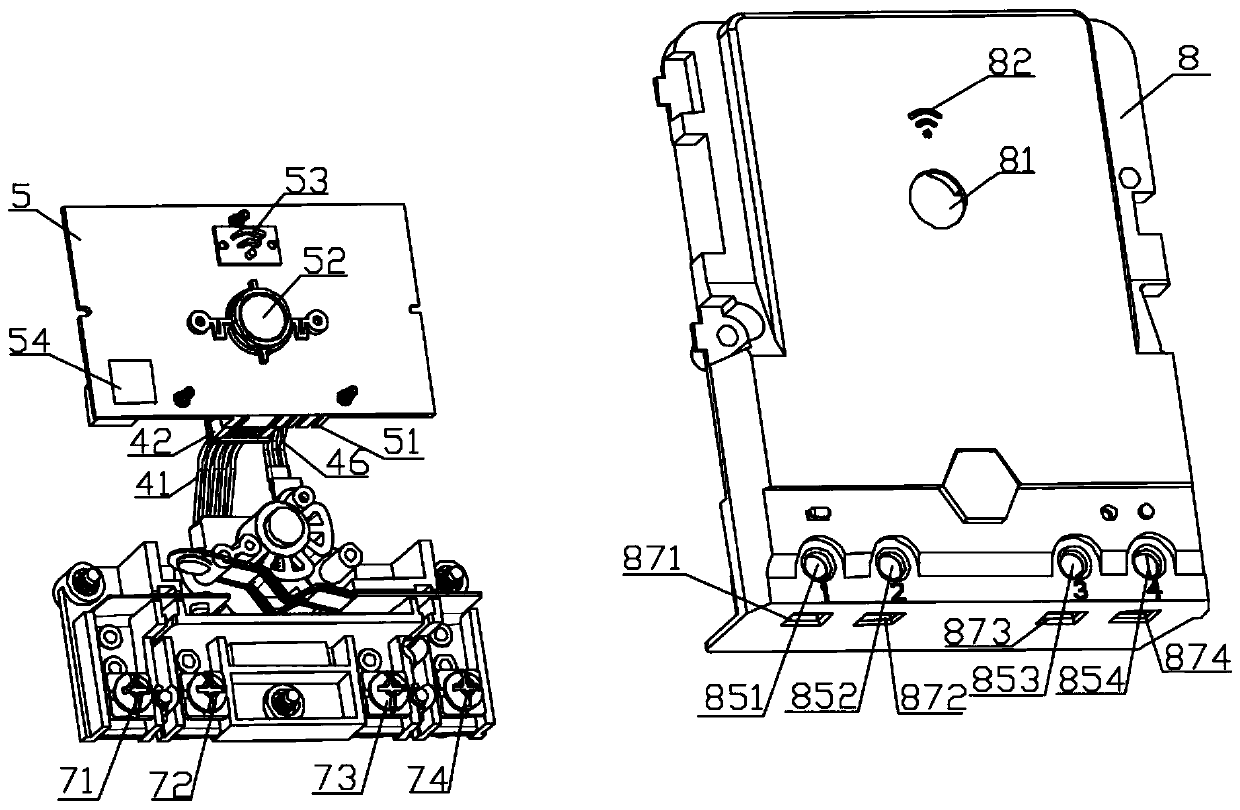

[0039] Such as Figure 1~4 As shown, it is an explosion diagram of a high-power electronic switch based on stepping motor control, such as Figure 6-11 Shown is the structural schematic diagram of the main body of the electronic switch. A high-power electronic switch based on stepping motor control, which includes: an electronic switch main body and a fixed box 8, the electronic switch main body includes an extra-thick current-carrying static contact conductive shrapnel 1, an extra-thick current-carrying static contact conductive shrapnel 2, L Shaped conductive shrapnel fixed plate 3, PCB board 5, plastic base 6, are characterized in that: also include stepper motor 4 and Hall element 45, stepper motor 4 is electrically connected with PCB board 5, stepper motor 4 and Hall element The Hall element 45 is electrically connected, the Hall element 45 is electrically connected to the PCB board 5, the power line of the PCB board 5 can be electrically connected to the load, and the n...

specific Embodiment example 2

[0047] Such as Figure 5 Shown is an exploded view of a high-power electronic switch based on stepper motor control. The difference with the specific implementation case 1 is that the high-power electronic switch based on stepping motor control also includes a protective case 9, and the protective case 9 includes an upper cover 91 and a lower cover 92, and the side of the upper cover 91 is provided with a first fixed shaft 911 and the second fixed shaft 912, the side of the lower cover 92 is provided with a first shaft sleeve 921 and a second shaft sleeve 922, the first fixed shaft 911 passes through the first shaft sleeve 921, and the second fixed shaft 912 passes through the second shaft sleeve 922, and the first fixed shaft 911 and the second fixed shaft 912 rotate synchronously in the first shaft sleeve 921 and the second shaft sleeve 922, so that the upper cover 91 and the lower cover 92 can be opened and closed, and the other one of the upper cover 91 A buckle frame 913...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com