Dilution device able to adjust ratio and dilution method

A dilution device and ratio technology, which is applied in the adjustable ratio dilution device and dilution field, can solve the problems of long time, low utilization rate and high cost, and achieve the effect of accurate dilution ratio, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

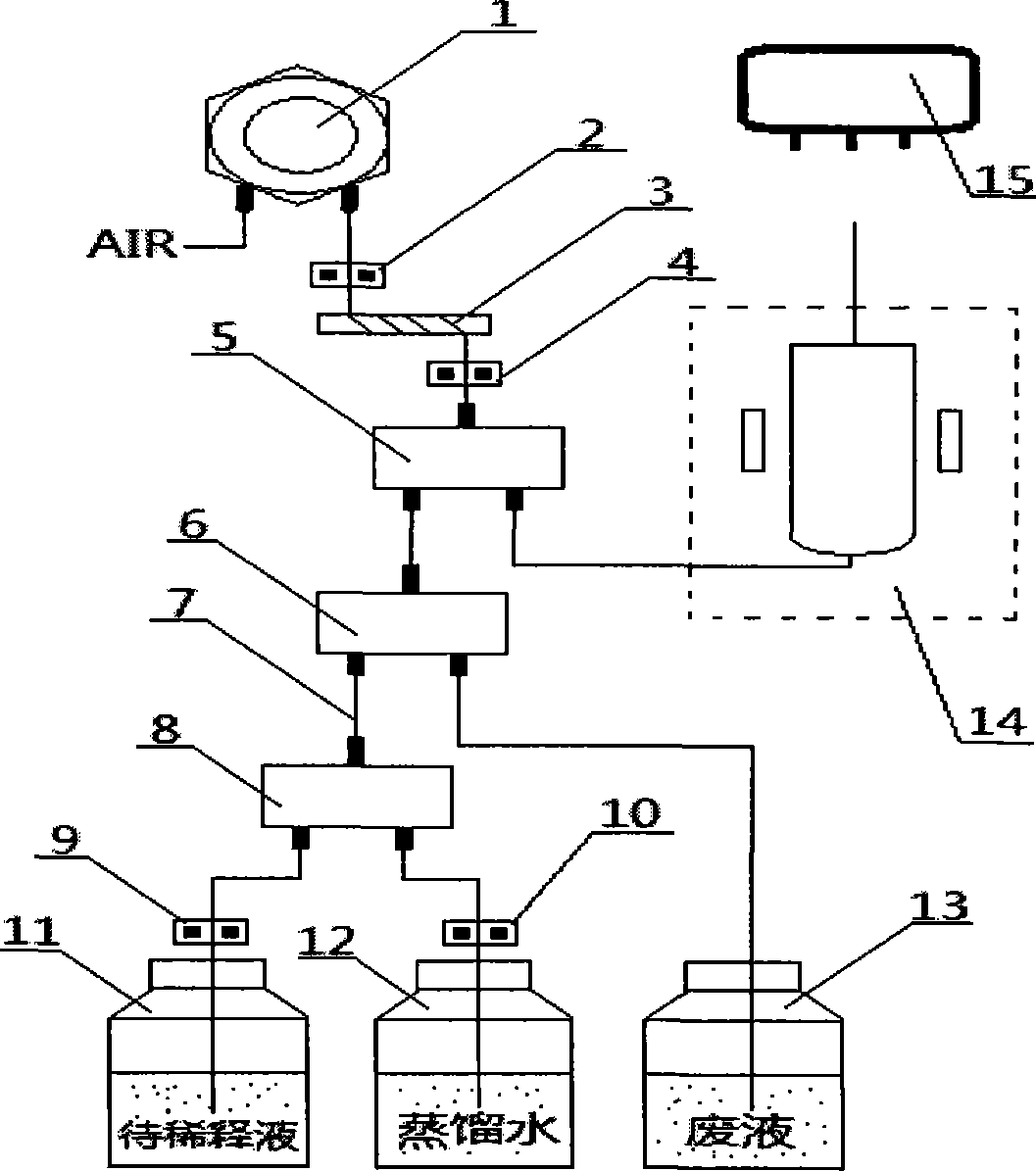

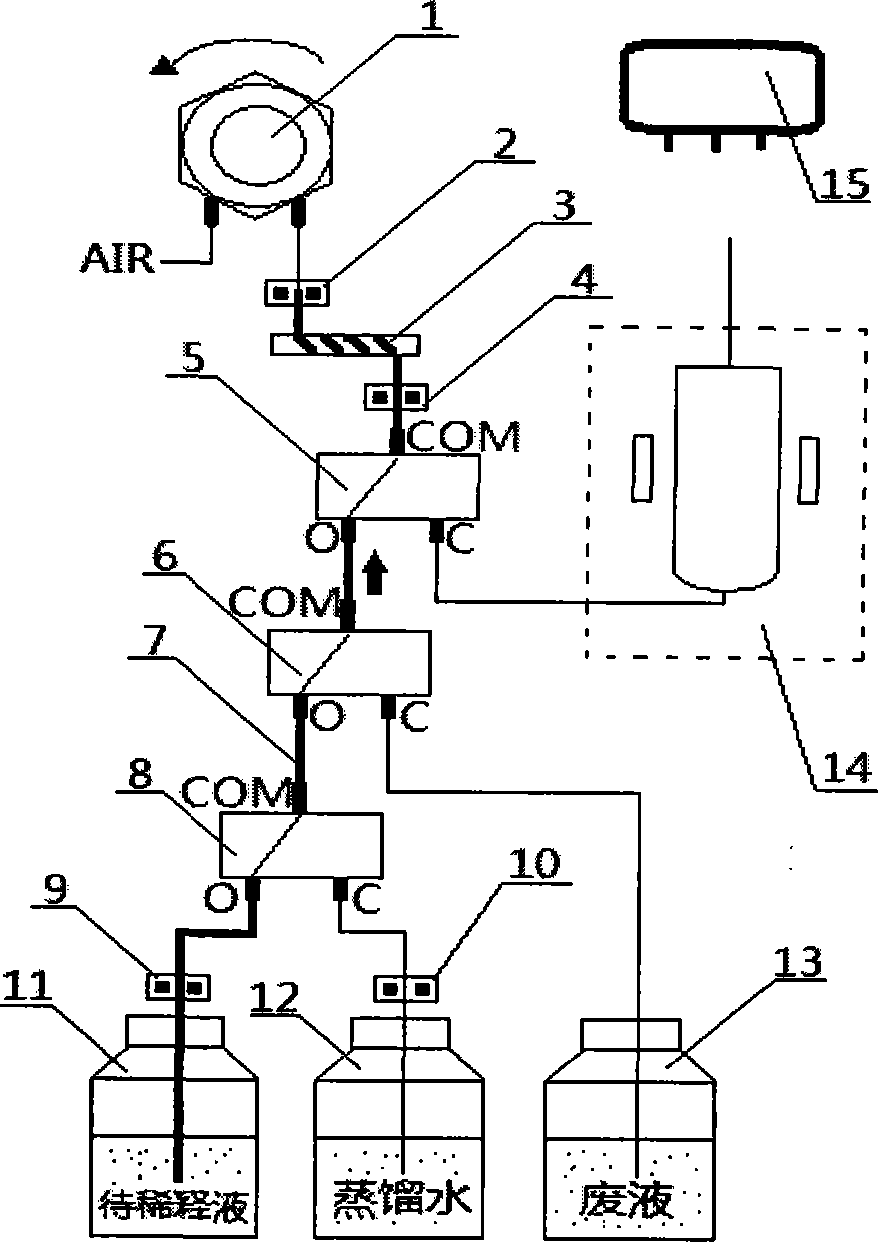

[0031] Such as figure 1 As shown, a dilution device with adjustable ratio includes: sampling pump 1, upper liquid level detector 2, liquid storage ring 3, lower liquid level detector 4, two-position three-way mixing valve 5, two-position three-way interception Valve 6, quantitative tube 7, two-position three-way sampling valve 8, liquid shortage detector A9, liquid shortage detector B10, reagent to be diluted 11, distilled water 12, waste liquid bucket 13, mixing vessel 14, controller 15. Among them, the normally open channel and the normally closed channel of the two-position three-way sampling valve 8 are respectively connected to the pipelines of the reagent to be diluted 11 and the distilled water 12, and the liquid shortage detector A9 and the liquid shortage detector B10 are installed on the connecting pipelines, and the two-position three-way The common channel of the sampling valve 8 is connected to the normally open channel of the two-position three-way shut-off valve...

Embodiment 2

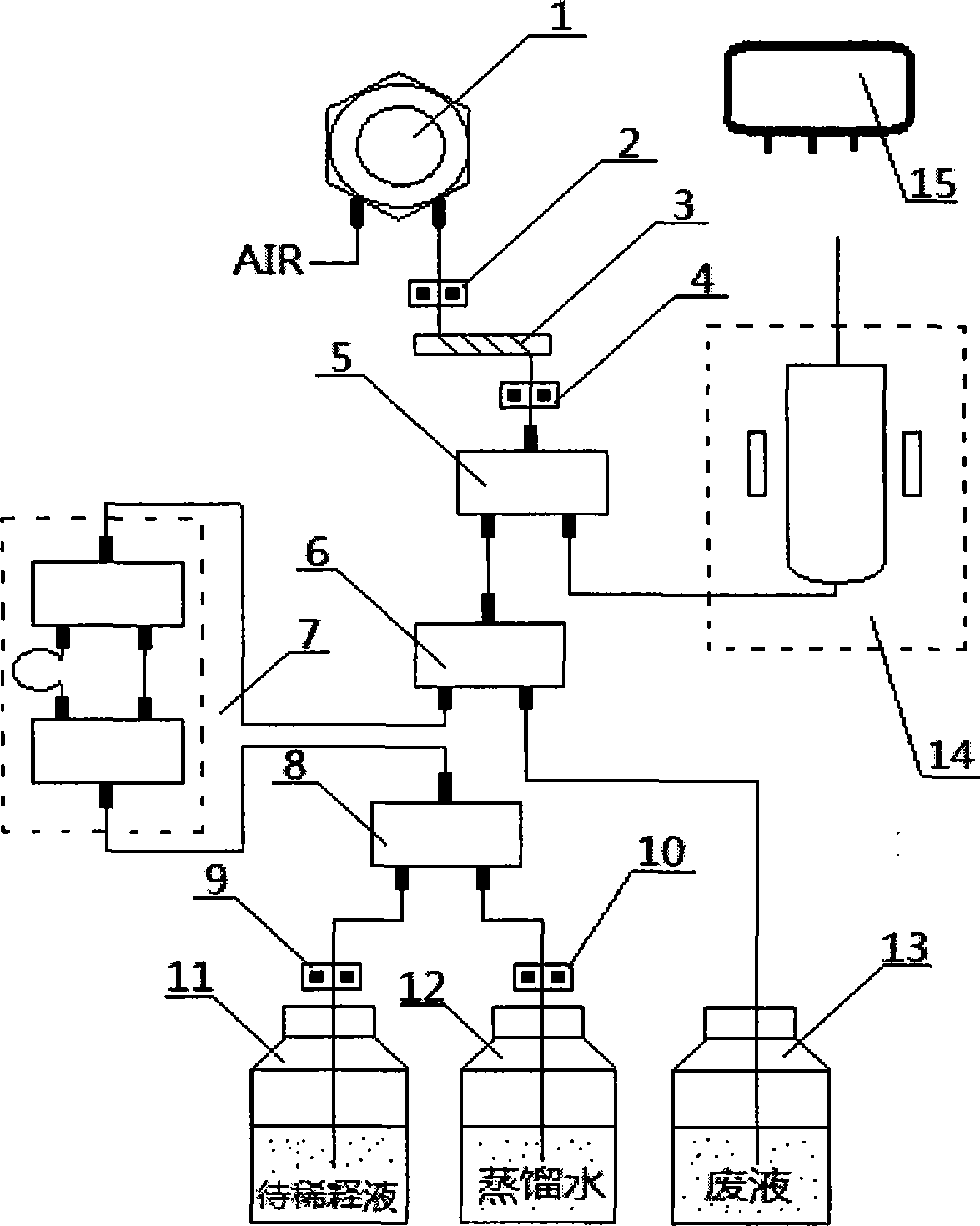

[0044] Such as figure 2 As shown, on the basis of Example 1, the quantitative tube 7 is removed and replaced with a combined connection of two two-position three-way valves, in which the normally open long pipes of the two two-position three-way valves are connected, and the normally closed short pipes are connected , the two common ports are respectively connected to the connection port of the metering tube 7, and the dilution process remains unchanged, switching the normally open and normally closed channels of the two two-position three-way valves can easily achieve two dilution ratios, so that By analogy, it can be extended to multiple dilution ratios, especially suitable for occasions that require automatic range switching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com