Powerplant with auxiliary compressor kept in operation in full-power phase

A technology that assists compressors and powertrains. It is applied in the direction of machines/engines, mechanical equipment, engine components, etc. It can solve the problems of reducing the pressure drop of the intake pipe without pointing out, and achieve the effect of reducing the pressure drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] It should be kept in mind that the drawings are given by way of example and not limitation of the invention. The drawings constitute schematic schematics to aid in the understanding of the invention and are not necessarily to scale for actual use. In particular, the dimensions shown for the various elements do not represent reality.

[0044] In the following, reference is made to all figures taken in combination. When reference is made to one or more specific figures, those figures should be used in conjunction with the other figures for identification of the assigned numerical reference numerals. In the following text, the terms upstream and downstream refer to the air flow in the intake duct passing from the air filter to the engine inlet.

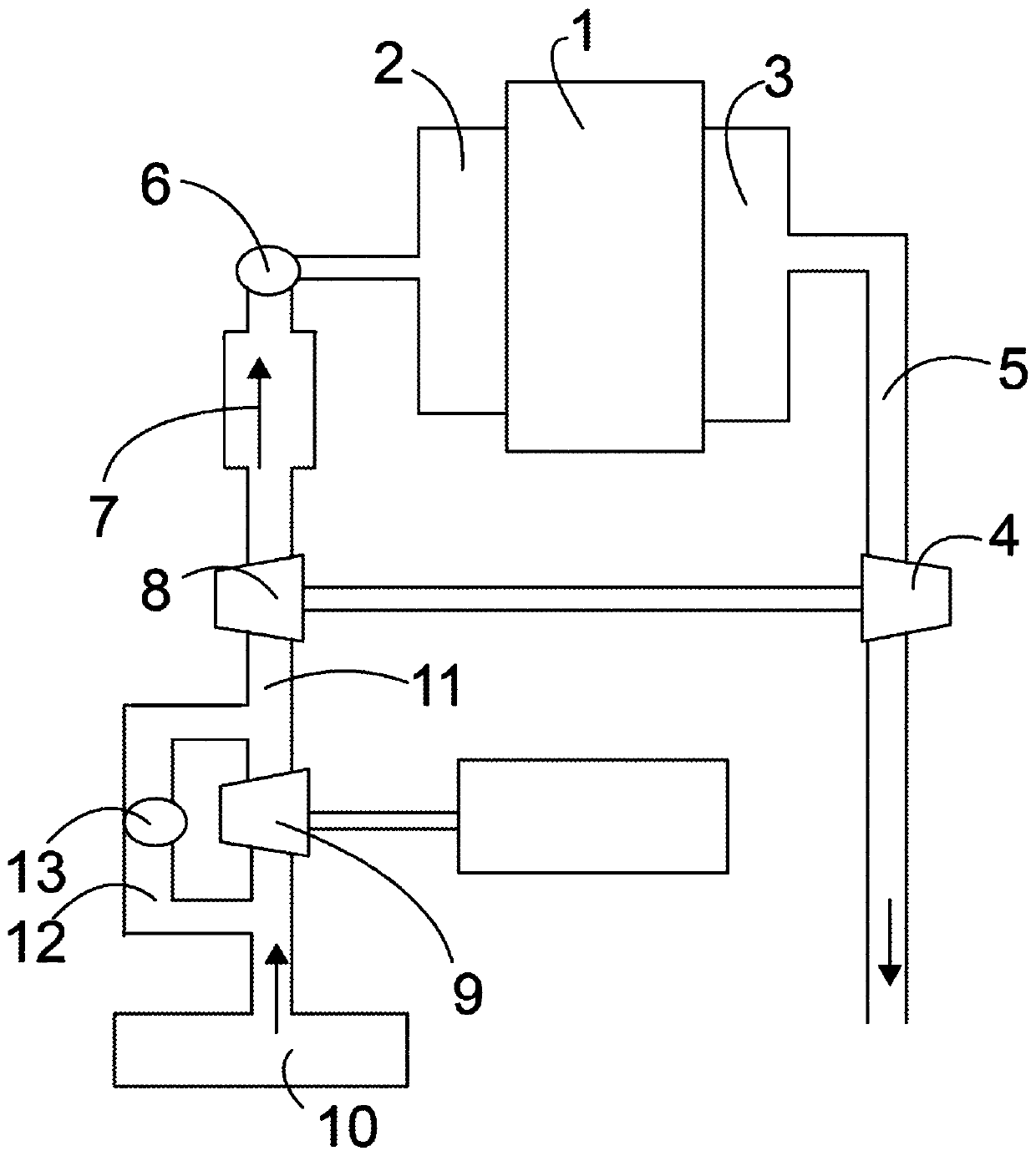

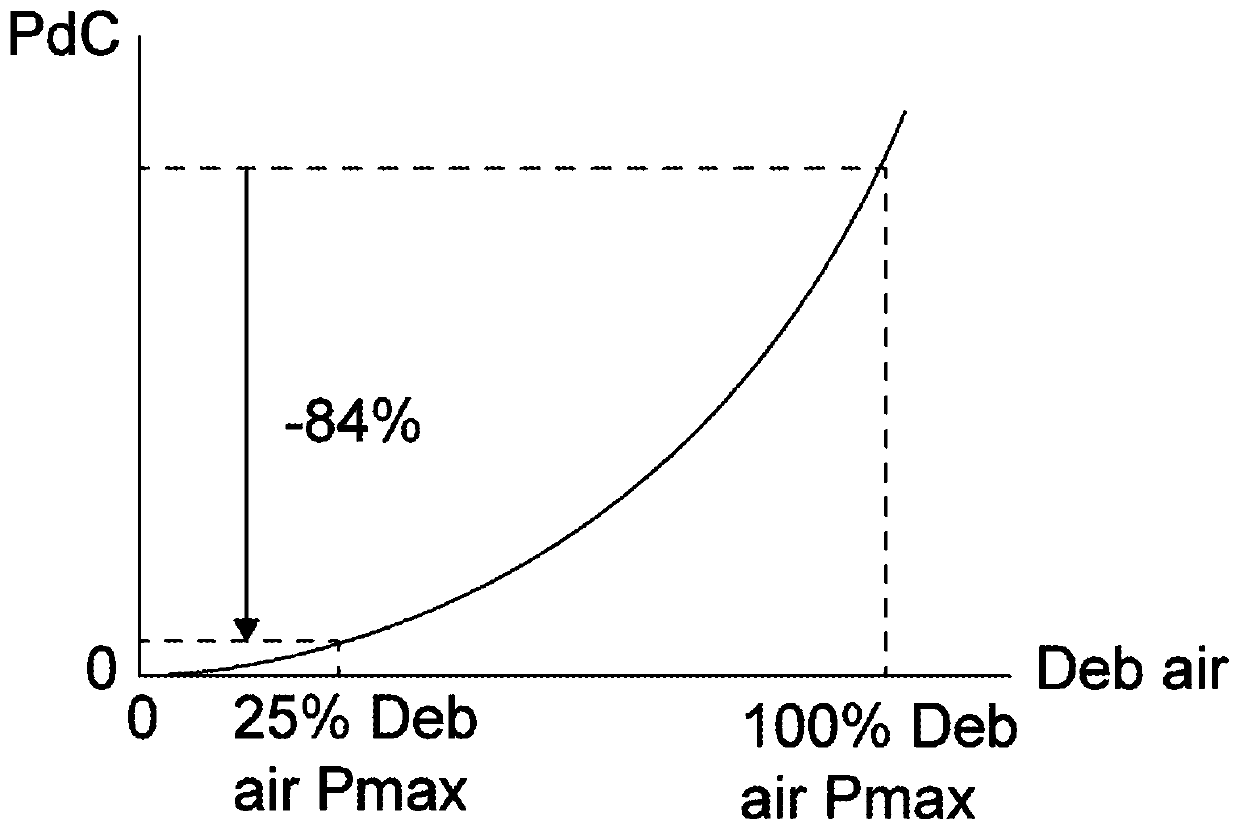

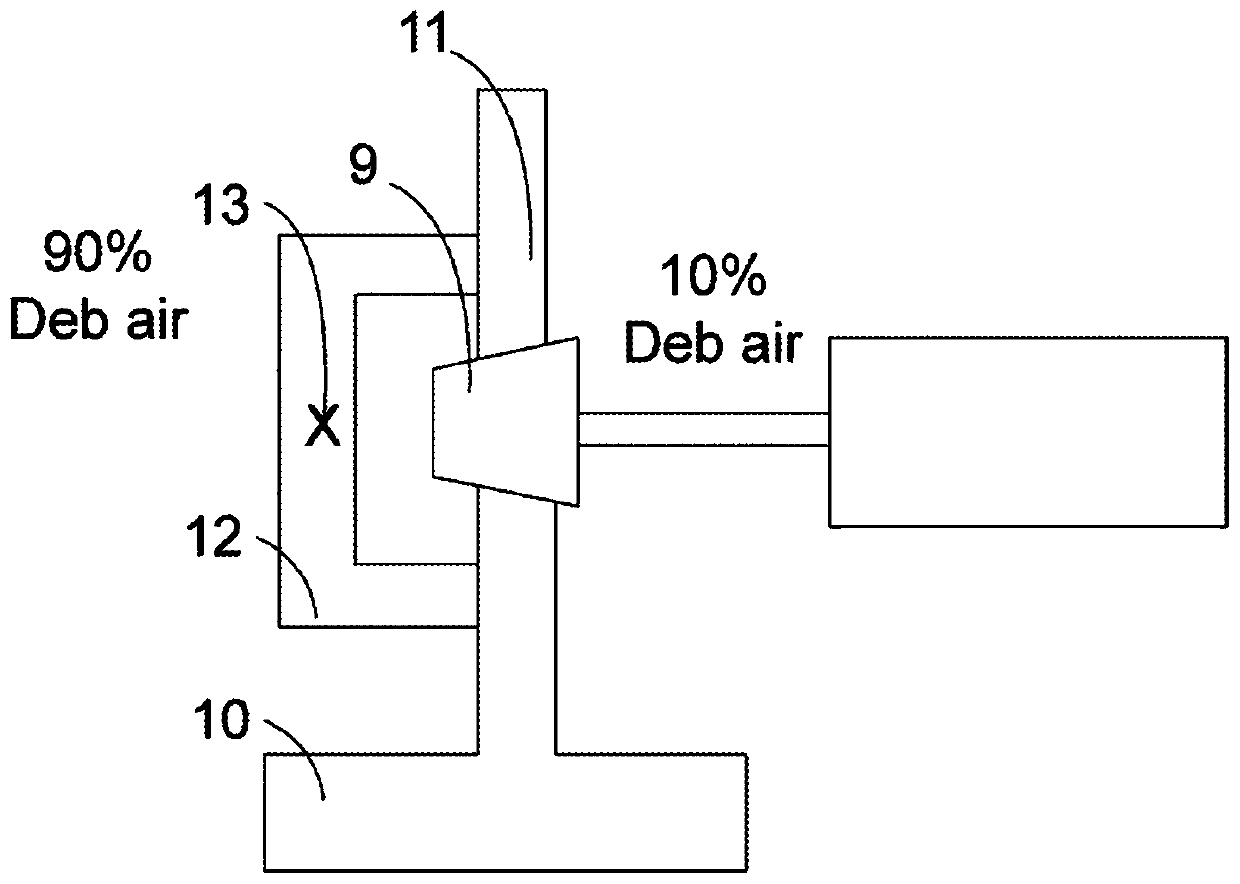

[0045] refer again figure 1 , wherein some features will be repeated, but all other preferred features have been described in the background part of the application, the invention is applicable to a motor vehicle powertrain com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com