Method of applying total station to irradiating alignment and positioning of ship axis

A total station, axis technology, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of small local operating space, low efficiency, complicated construction steps, etc., to achieve assembly positioning and precision detection, and easy assembly The effect of positioning and accuracy detection, precise three-dimensional positioning and high-precision digital display readings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A method of using a total station to illuminate and locate the axis of a ship,

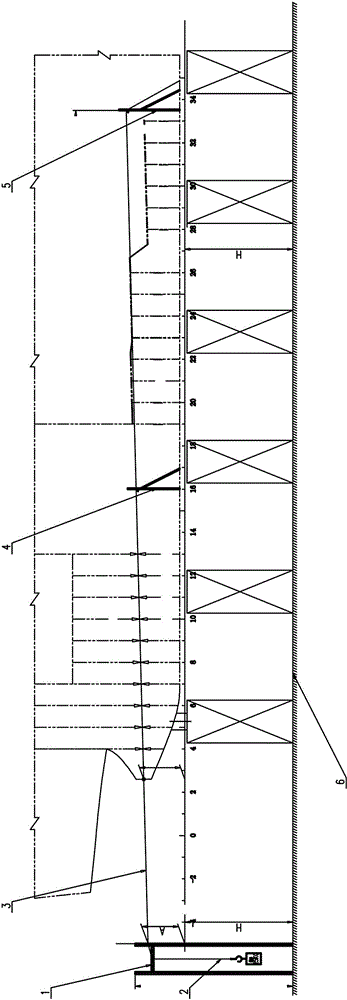

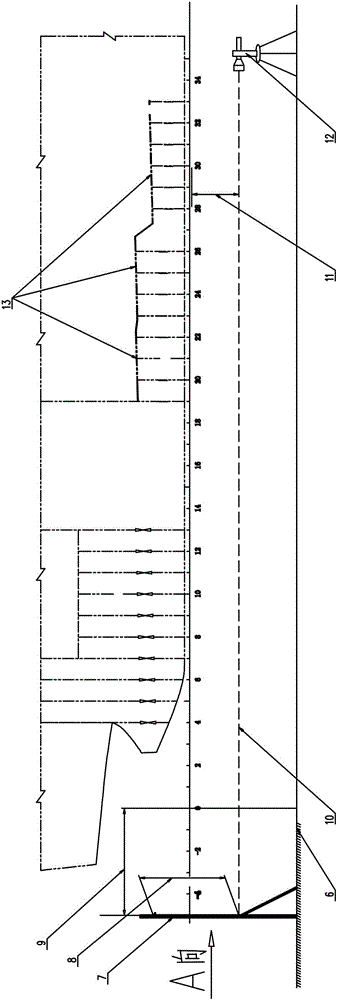

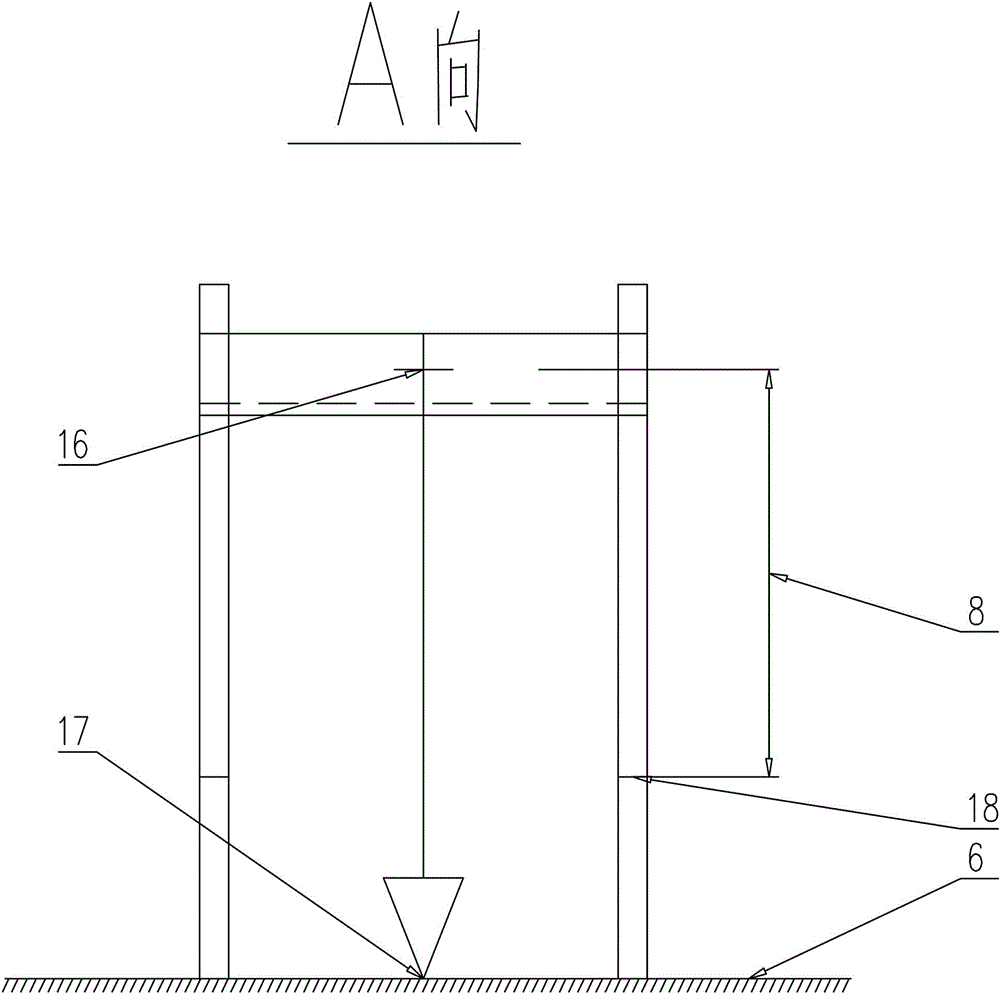

[0023] 1) if figure 2 , image 3 In the process, a reference total station 12 is set on the berth ground 6, a ray 10 parallel to the berth, a longitudinal line 17 on the berth ground, and a vertically measured design theoretical value 8 are generated by the total station telescope, and the theoretical reference point is transferred to the design theoretical value 8. On the reference target frame 7 at the stern, generate a reference target point 16;

[0024] 2) if Figure 4 In the process, a horizontal working platform 20 is set on the side of the reference target frame 7 away from the stern, and the three-dimensional space position of the total station 19 located on the horizontal working platform 20 is adjusted, and the laser beam of the total station 19 passes through the reference target point 16 Generate the laser beam ray 14 of the centering total station that coincides with the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com