Fillet weld inflation test method

A technology of inflatable test and fillet weld, which is applied in the test field, can solve problems such as berth cycle and latent leakage that are not conducive to the integrity of segmental coating, and achieve the optimization of the tightness test operating environment, reduce energy consumption, and reduce work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

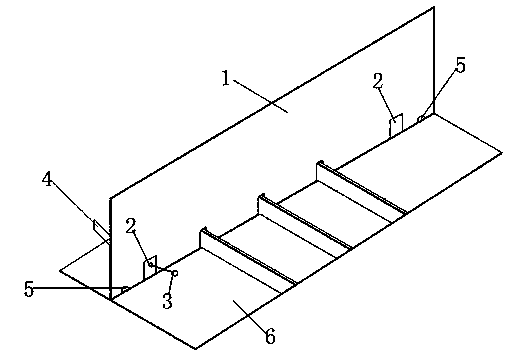

[0022] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0023] Fillet weld filling test method of the present invention comprises the following steps:

[0024] Step 1: Open the valve, inject compressed air into the root gap of the fillet weld, and when the pointer on the pressure gauge reaches the specified pressure value, close the valve and press static pressure for fifteen minutes; the specified pressure value on the pressure gauge in Step 1 is 0.015Mpa ~0.02Mpa.

[0025] Step 2. Check whether the pointer of the pressure gauge has dropped. If there is a significant drop in the static pressure within 15 minutes, check the leakage of the joint weld and find the cause of the pressure drop; Apply soap liquid on the surface, check whether there is bubble phenomenon on the surface of the weld, and it is considered qualified when there is no bubble in the inspection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com