Large-sized aerial work platform for shipbuilding

A high-altitude work platform and platform technology, which is applied in slipways, dry docks, ships, etc., can solve the problems of limited personal working area, narrow scaffolding operation surface, and inability to replace scaffolding, etc. The effect of shortening the occupancy cycle of the slipway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

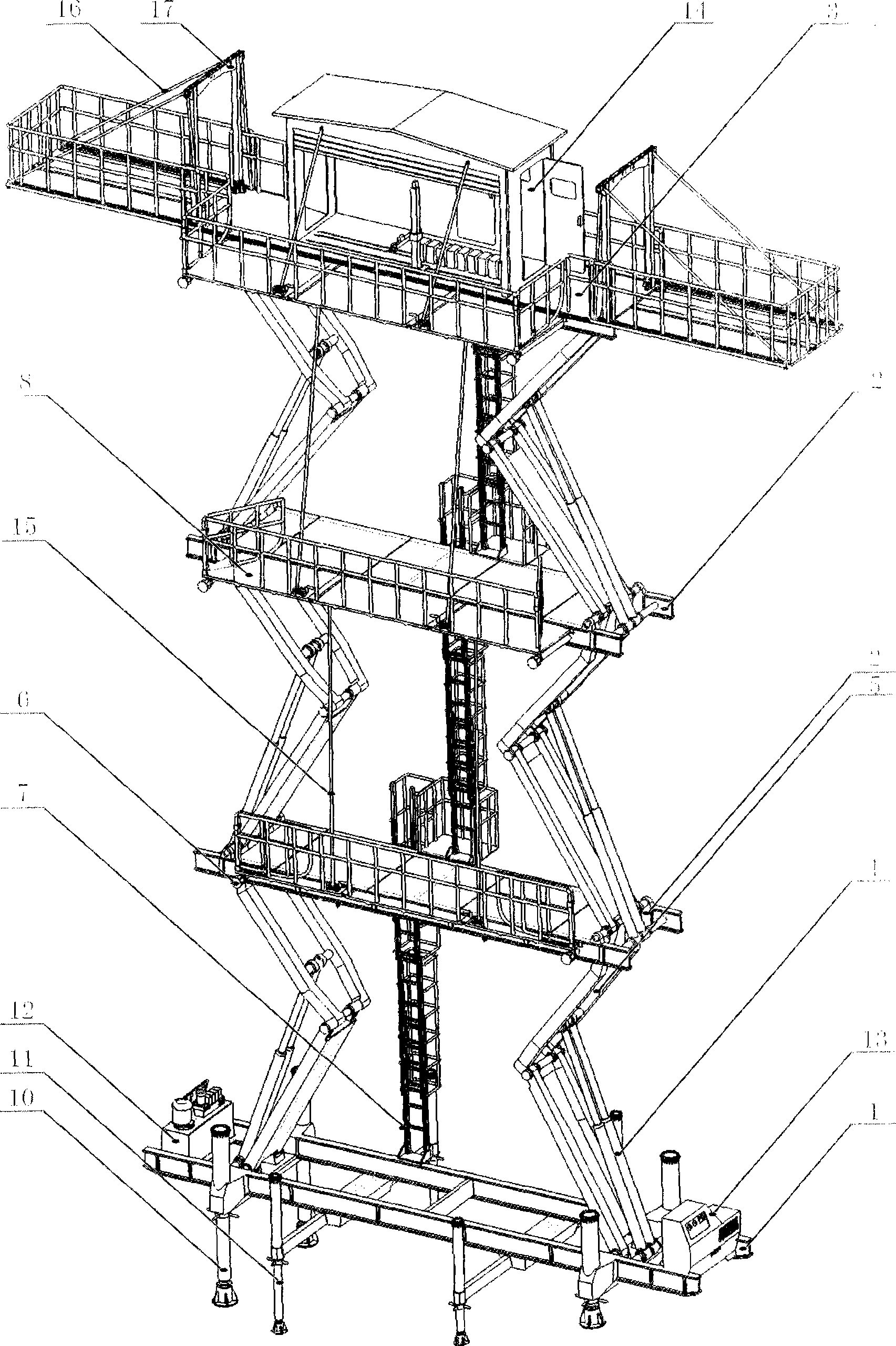

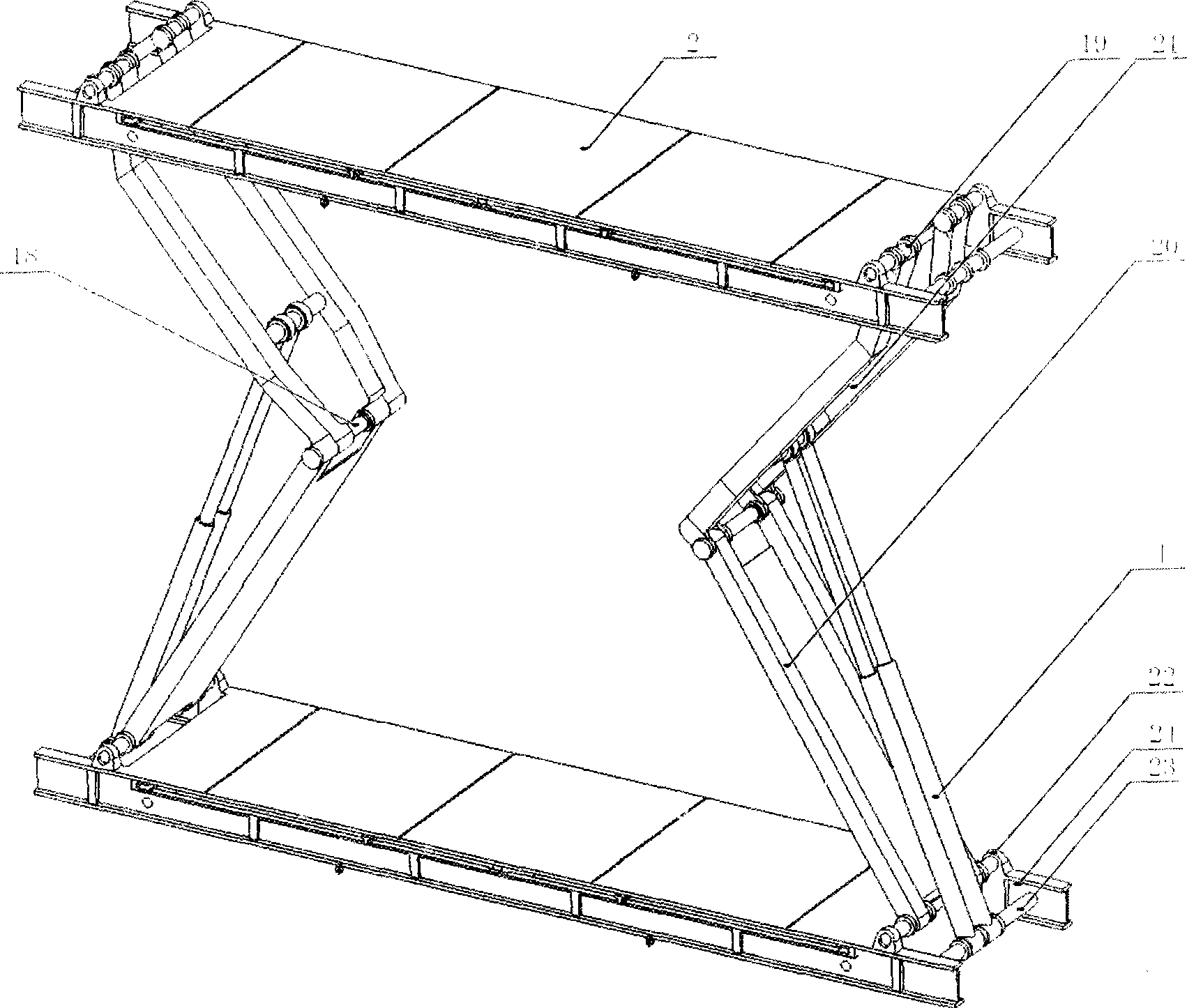

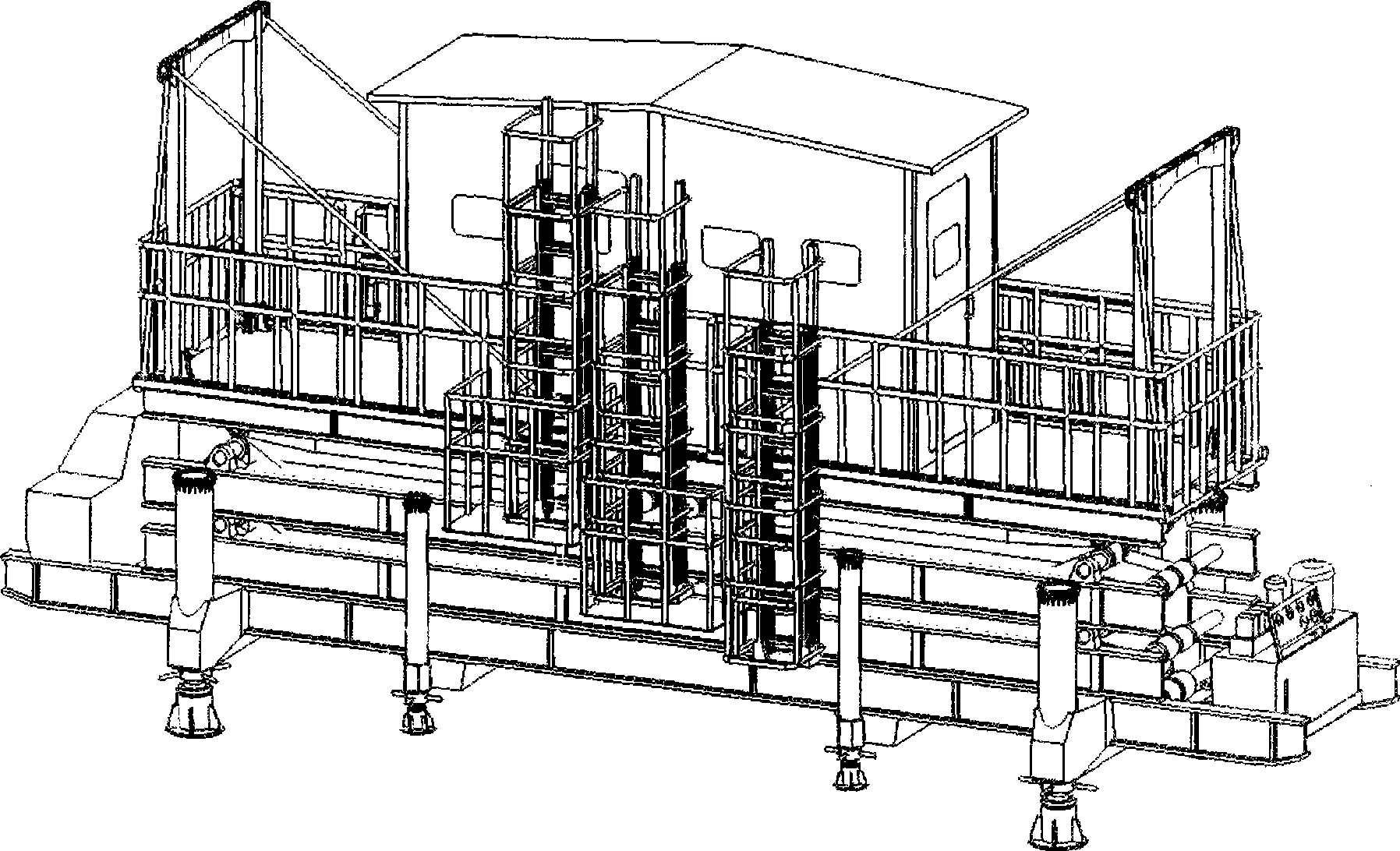

[0026] Such as figure 1 As shown, the present invention is composed of a base platform 1, a transition platform 2, a top platform 3, a hydraulic system, an electric control device, an electromagnetic fixing device, and a side support electromagnetic adsorption cylinder 6. Each platform is connected and supported by a support frame 5 with a lifting cylinder 4 and is magnetically attracted to the hull by a side support electromagnetic adsorption cylinder 6. Each platform is equipped with an escalator 7 to facilitate up and down during construction. The transition platform 2 and the top platform 3 are on the ship. A ship-direction extension platform 8 is provided, and the top platform is also provided with a forward-direction extension platform 53 along the length of the ship. The base platform 1 is supported on the berth by four fixed vertical telescopic support legs 10 and four horizontal and vertical telescopic support legs 11. A hydraulic station 12 is installed at the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com