Tri-dimensional oral prosthesis in vitro grinding and repairing emulated testing machine

A technology for dental prostheses and testing machines, which can be used in dental prostheses, mechanical devices, medical science, etc., and can solve problems such as gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

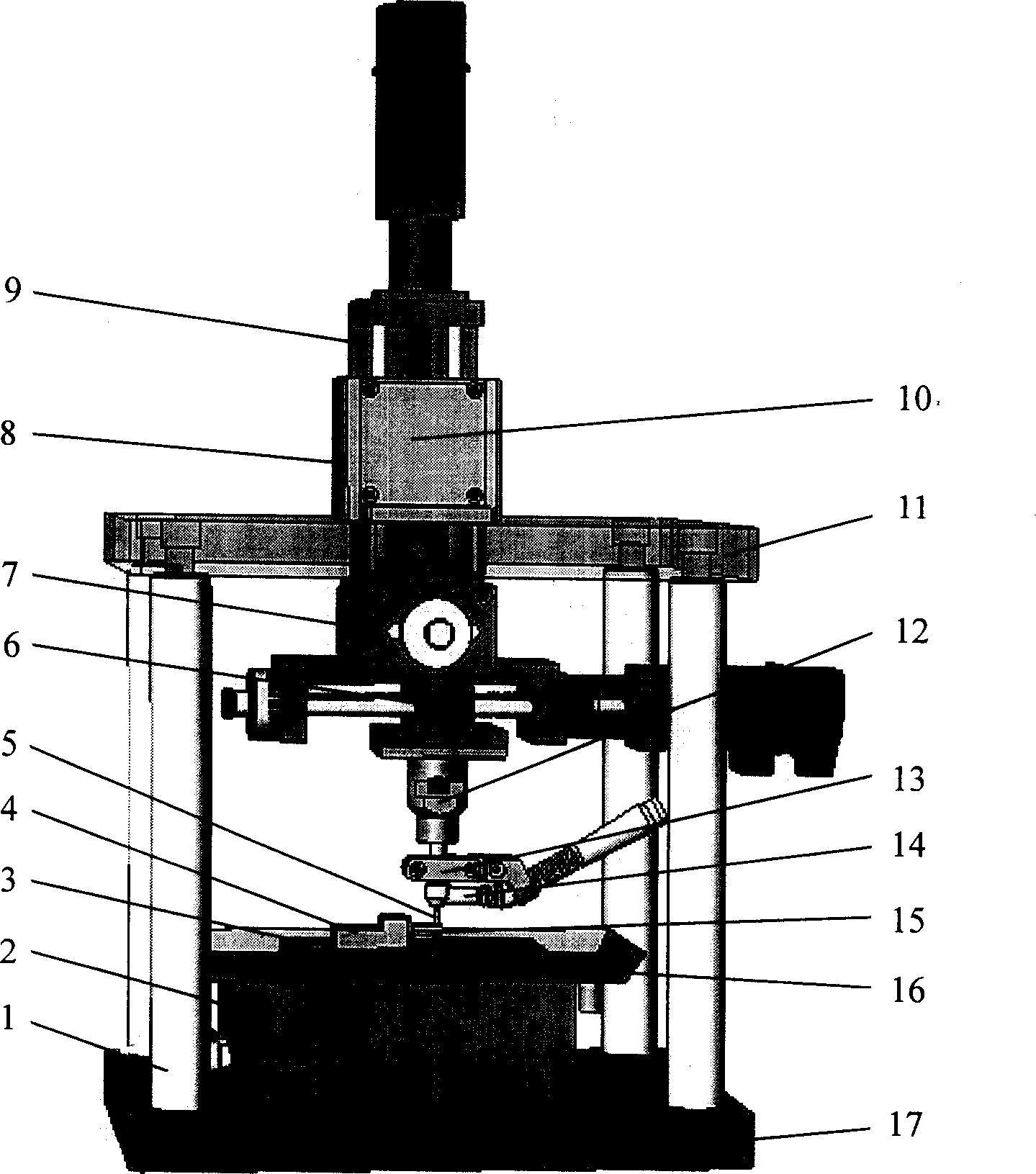

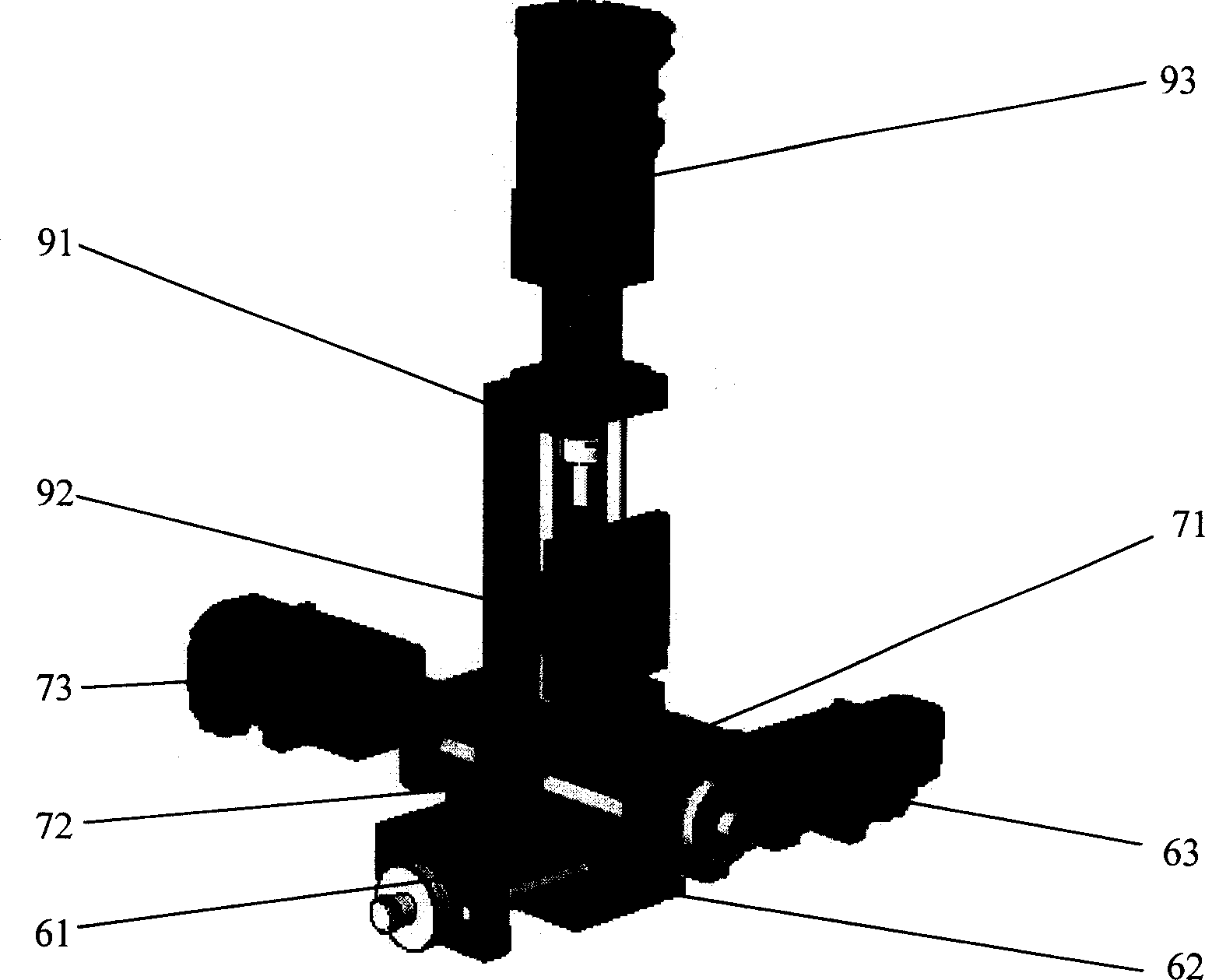

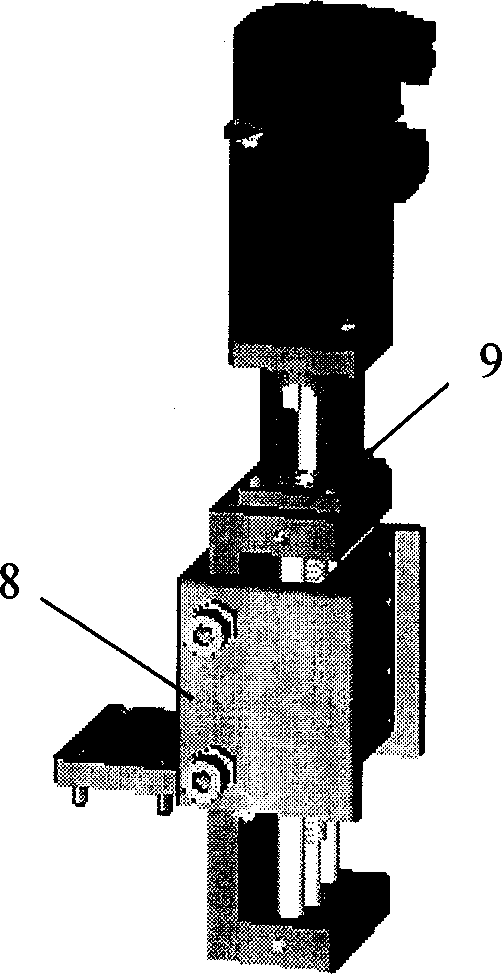

[0024] The present invention is a kind of three-dimensional dental prosthesis in vitro grinding repair testing machine, this testing machine ( figure 1 ) includes four columns 1, which are rigidly connected with the lower base plate 17 and the upper top plate 11, and they form a frame. The size of the rack is small, its length, width and height are: 300×250×250mm. The upper top plate and the lower bottom plate have a high degree of parallelism, thus ensuring that the 3D CNC workbench can run precisely according to the established requirements. 3D CNC coordinate table ( figure 2) consists of three numerically controlled workbenches with the same structure: a workbench 6 capable of moving left and right in the X direction, a workbench 7 capable of moving forward and backward in the Y direction, and a numerical control workbench 9 capable of moving up and down in the Z direction, and the axes of the three workbenches are in the The space is distributed vertically. Each workbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com