Full-automatic quail cultivating cage

A fully automatic, quail technology, applied to the field of equipment used in the poultry breeding industry, can solve the problems such as the difficulty of automatic feeding, the inability to realize automatic breeding, and the easy failure of the transmission structure, so as to facilitate maintenance and management and reduce labor. cost, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

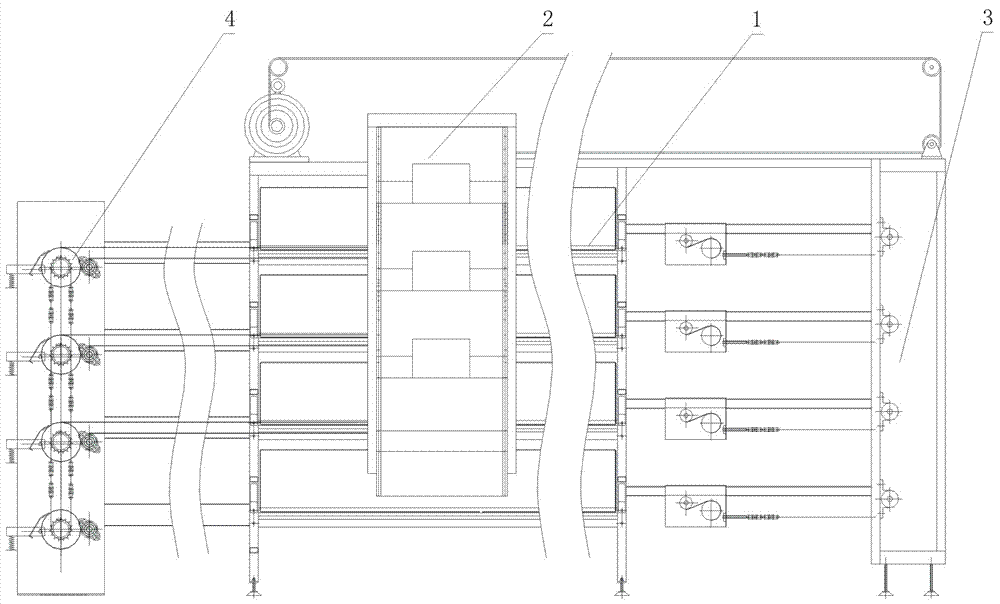

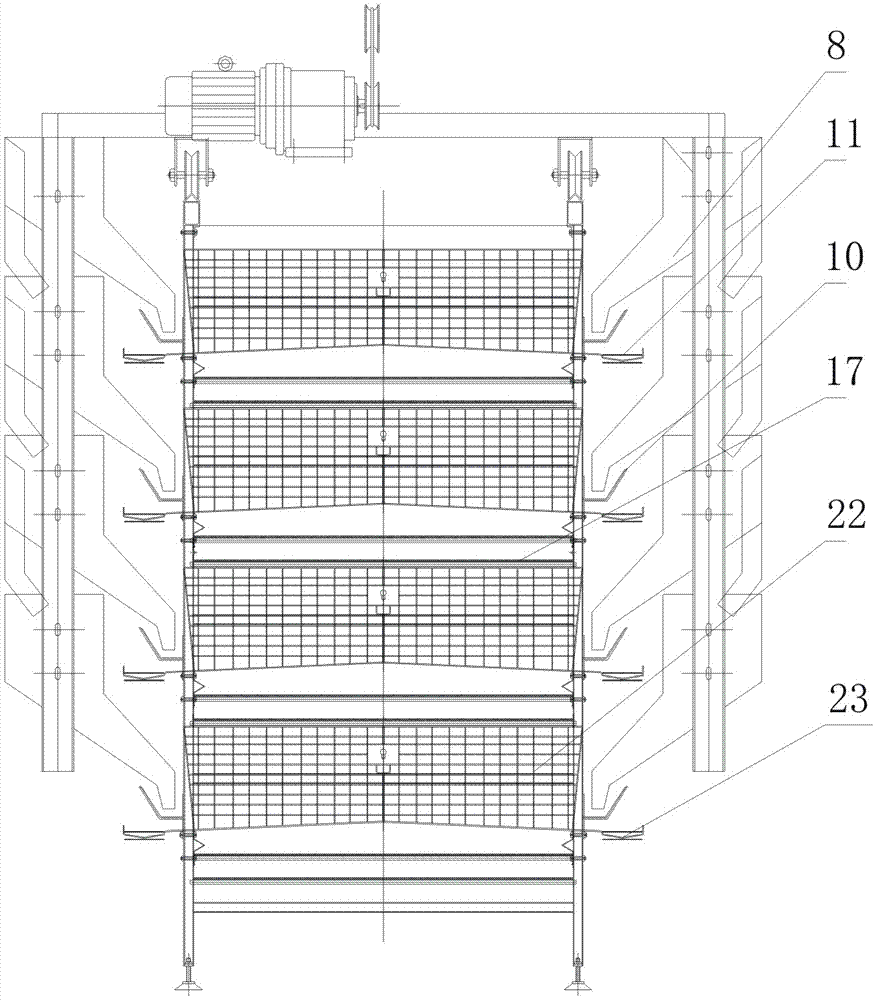

[0023] Such as figure 1 , 2 As shown, it includes a laminated frame 1 made up of columns and beams, the frame is 4 layers, and a cage 22 is provided on each layer of frame 1, and a feeding device 2 is provided on both sides of the corresponding cage. The feeding device 2 slides along the cage through the slideway 9 on the frame. The bottom of the cage 22 is an inclined bottom, and an egg trough 23 is arranged on the outside of the cage, and an egg belt 11 is arranged on the egg trough, and an egg belt 11 Configured with the egg collection device 3 provided on the frame, the bottom of the cage on the frame is provided with a manure belt 17, and the manure belt is configured with the manure removal device 4 provided on the frame.

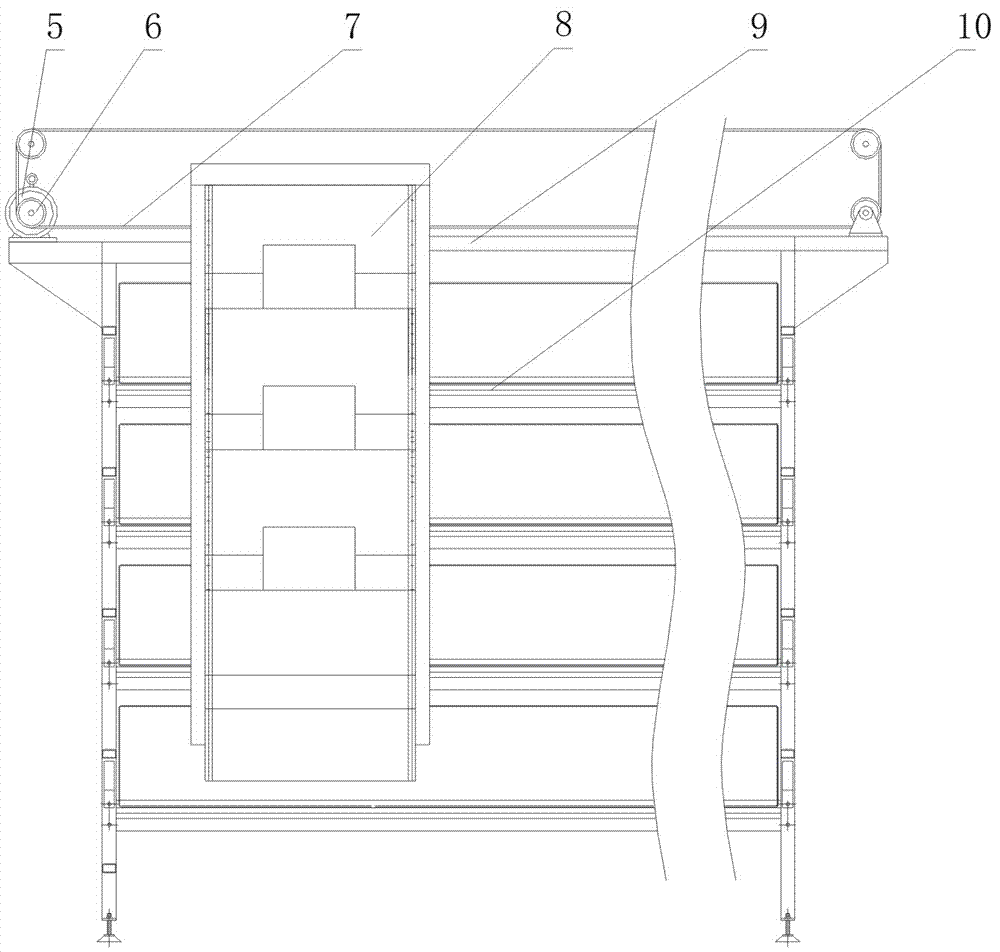

[0024] Such as image 3 As shown, the feeding device 2 includes a stacked feeding frame, and a hopper 8 is provided on each layer of the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com