Synthetic inspection tester for shaft element

A technology for parts and inspection instruments, which is applied in the field of special equipment for comprehensive detection of geometric parameters, can solve the problems that the three-coordinate measuring machine is difficult to meet the requirements, cannot be combined together, and the equipment is difficult to detect, and achieves small deformation and stability. Good, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

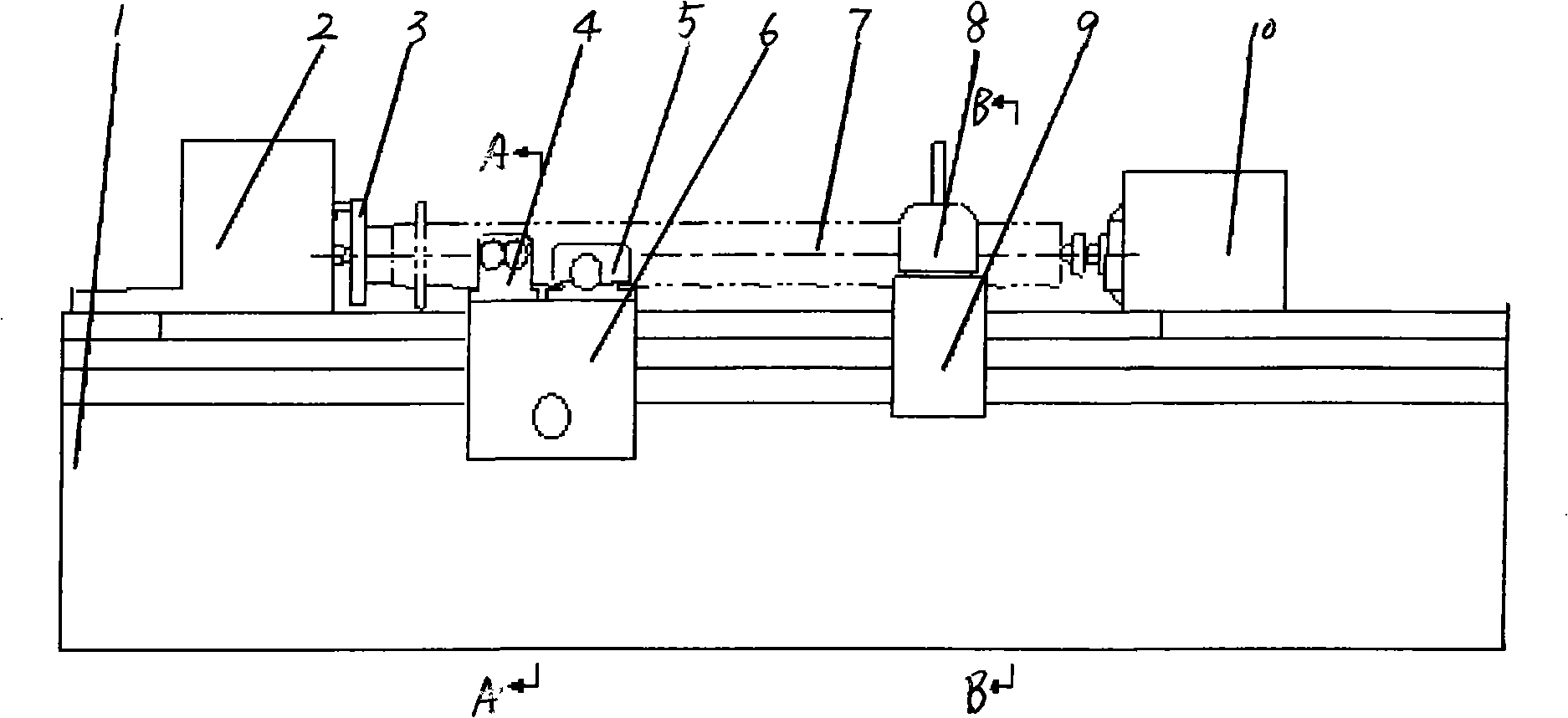

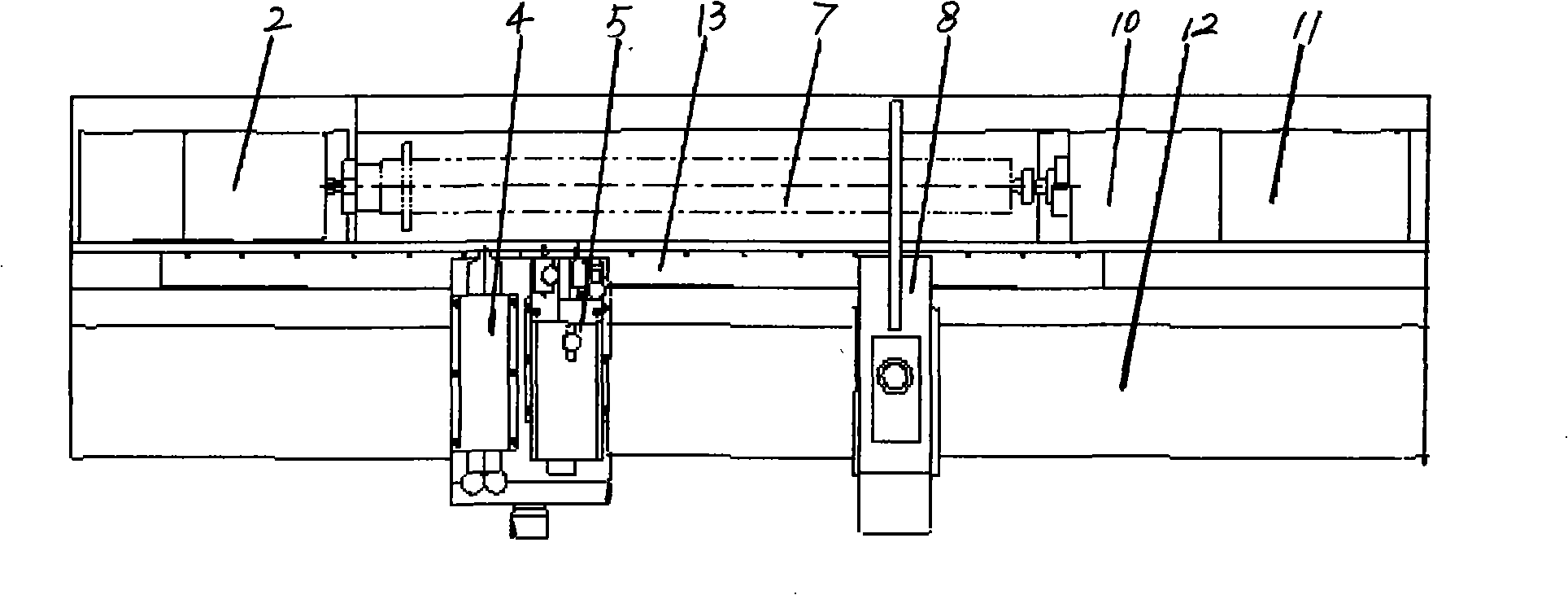

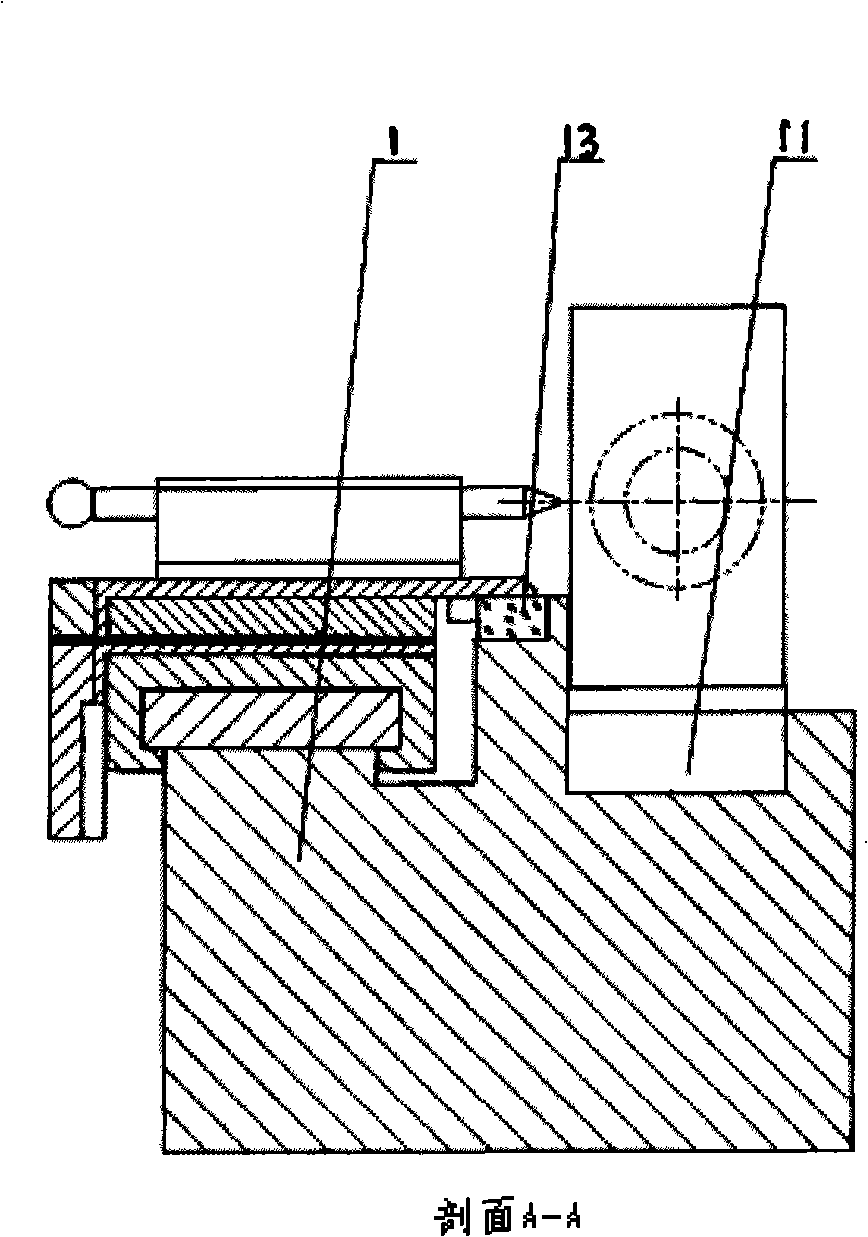

[0019] A comprehensive inspection instrument for shaft parts, using granite materials to process the base 1, and processing two parallel air-floating guide rails on the base 1, which are respectively used as measuring guide rails 12 and load-bearing guide rails. The load-bearing guide rails are equipped with load-bearing slides 11, Measuring slides 6 and 9 are equipped on the measuring guide rail, and air flotation air circuit and vacuum adsorption air circuit are respectively installed on the load-bearing slide 11, slide 6, and slide 9. When the air flotation air circuit is ventilated, the gas can be Let the sliding table float a few microns to tens of microns for easy movement, and when the vacuum adsorption chamber is evacuated, the sliding table can be firmly fixed due to the pressure difference. A headstock 2 and a tailstock 10 are installed respectively on the left end of the base and the load-bearing guide rail 11, and the top alignment straight line of the headstock 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com