Tunnel waterproof board spreading and hanging device

A tunnel waterproof board, paving and hanging technology, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems that cannot meet the construction requirements of different tunnels, and achieve the effects of low manufacturing cost, easy use, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

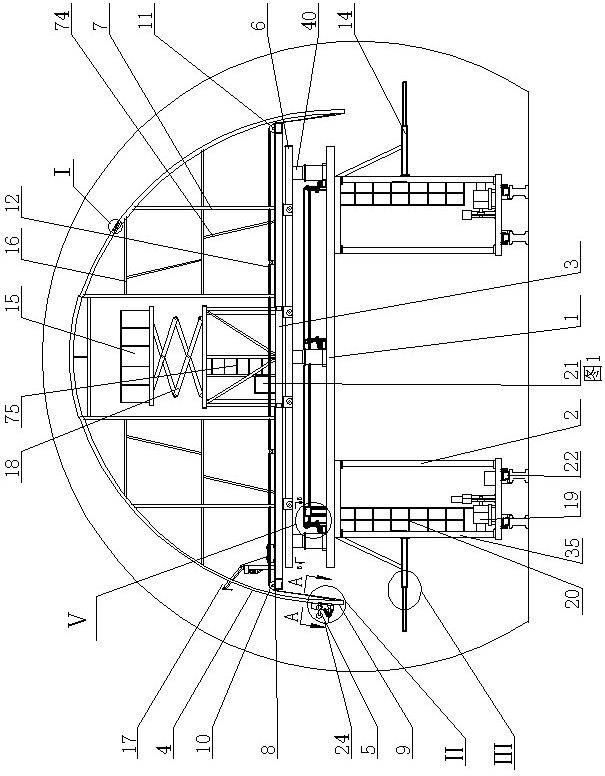

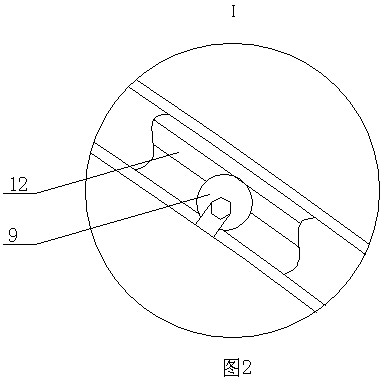

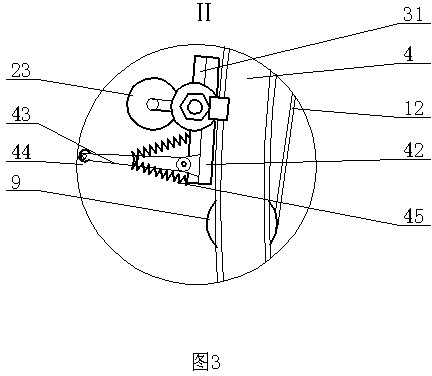

[0009] A kind of tunnel waterproof board paving and hanging device according to the present invention, such as figure 1 As shown, it includes a base 1, a longitudinal moving device 2, an upper bracket 7, an arc-shaped guide rail 4 and a hanging trolley 5, the bottom of the base 1 is installed with a longitudinal moving device 2, and a horizontal guide rail 6 is installed on the base 1, and on the horizontal guide rail 6 A horizontally moving dolly 3 that can slide along the horizontal guide rail 6 is installed, and an upper support 7 is fixedly installed on the laterally moving dolly 3. Two arc guide rails 4 are installed on the upper support 7, and a paving and hanging dolly 5 is installed on the two arc guide rails 4. Hanging dolly 5 can slide along arc guide rail 4. When in use, first move the present invention to the tunnel that needs to be constructed by the longitudinal moving device 2, move the laterally moving trolley 3 to the left so that the paving and hanging trolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com