Automatic circulating feeding and material storing AOI detecting equipment

A technology of automatic circulation and detection equipment, which is applied in sorting and other directions, and can solve the problems of inability to carry out effective circulation storage and unloading operations, and slow loading and detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

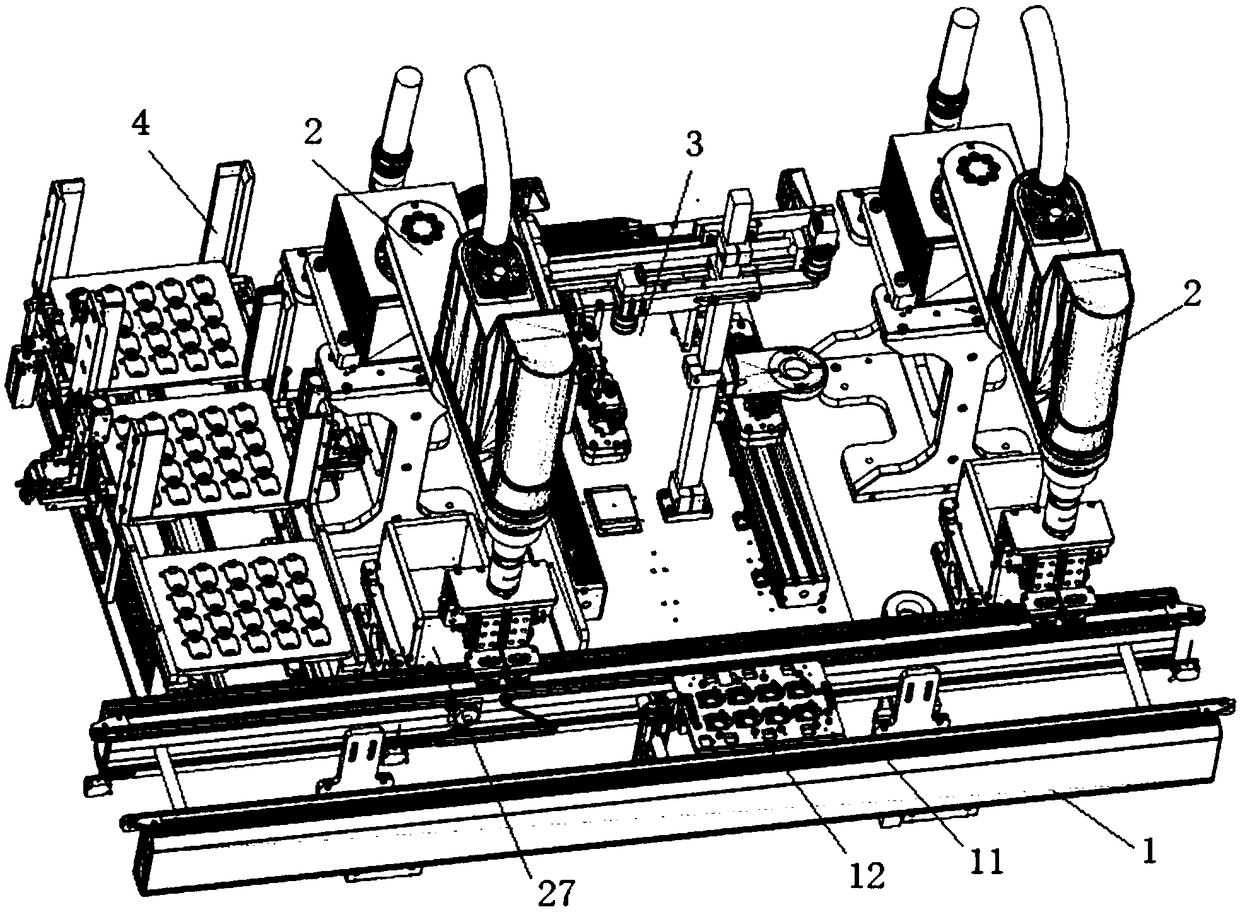

[0030] refer to Figure 1-8 As shown, this embodiment is an automatic cycle feeding and storage AOI detection equipment, including a feeding transmission component 1, a mechanical arm suction component 2, an AOI detection component 3 and a revolving vehicle supply bin component 4;

[0031] The above-mentioned components are all set on the workbench. The AOI detection component 3 and the turnover carrier supply bin component 4 are installed on the side of the feeding transmission component 1. Two sets of mechanical arm suction components 2 are respectively set on the side of the AOI detection component 3. And turnover carrier feed bin assembly 4 sides.

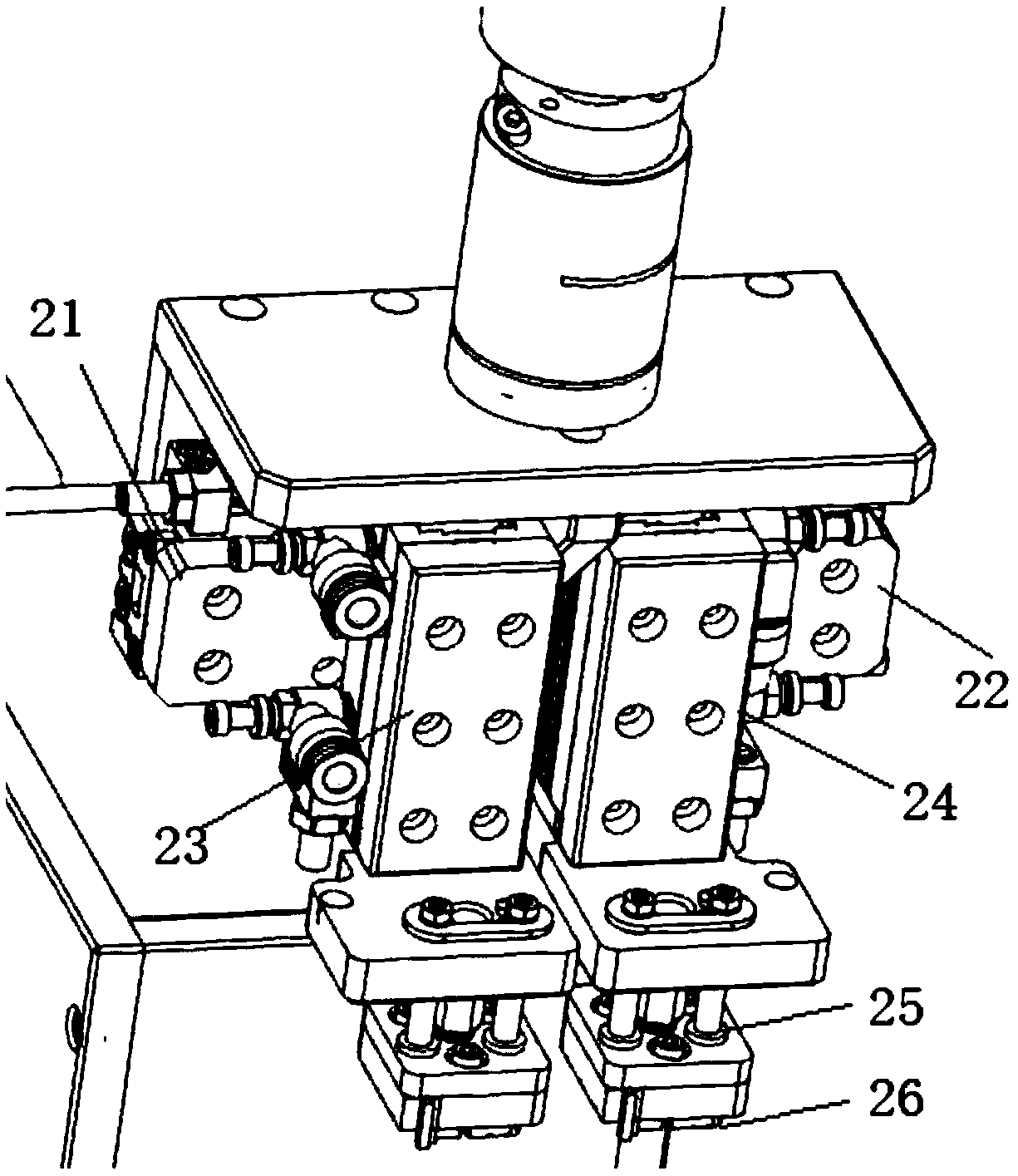

[0032] The mechanical arm suction component 2 transfers the products sequentially from the feeding and conveying component 1 to the AOI detection component 3 and then to the turnover carrier supply bin component 4 .

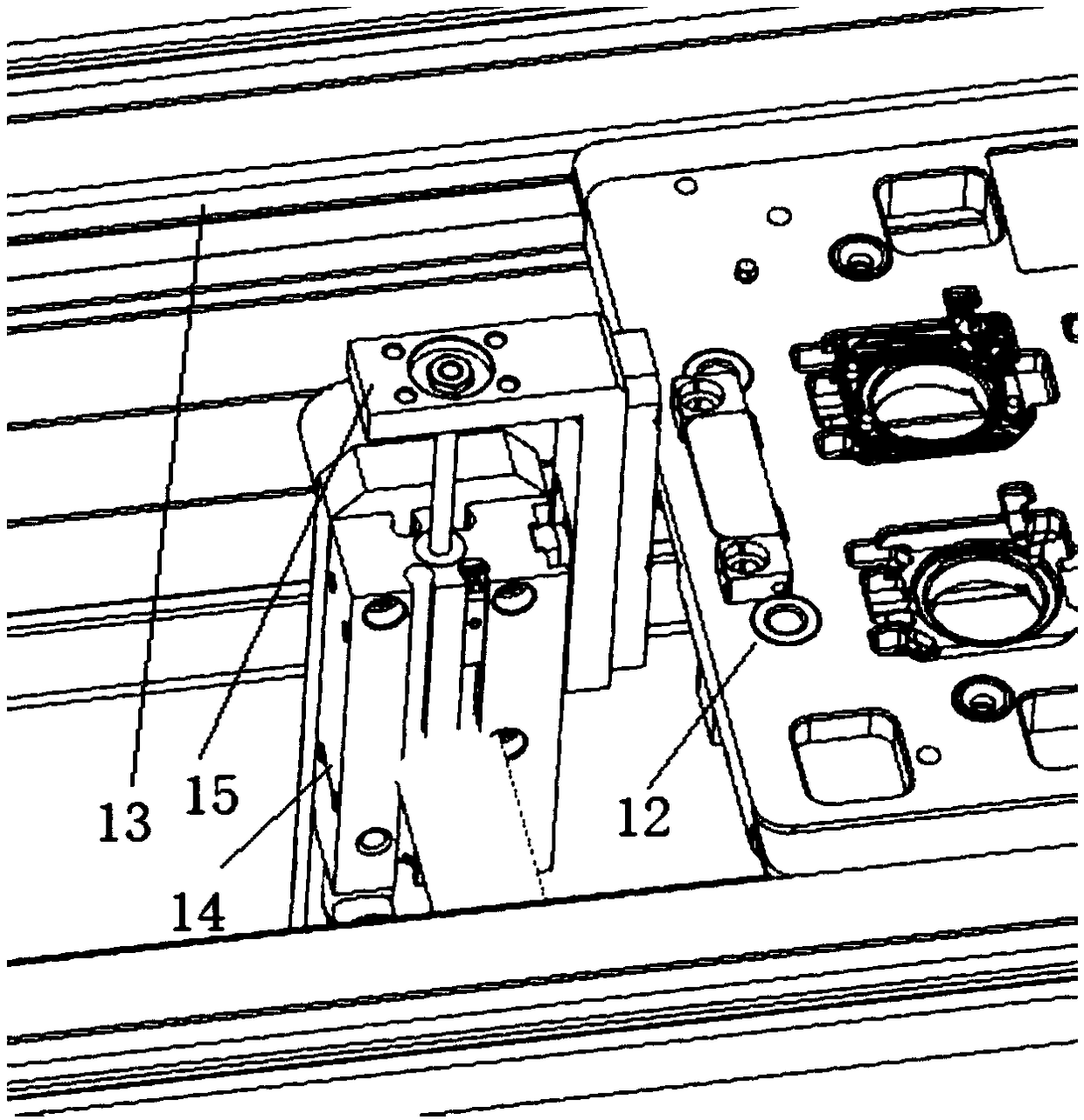

[0033] The feeding transmission assembly 1 includes a horizontally symmetrical linear slide rail 11, a product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com