Granular powder

A technology of granule powder and wheat flour, applied in the field of granule powder, to achieve the effect of good operability and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

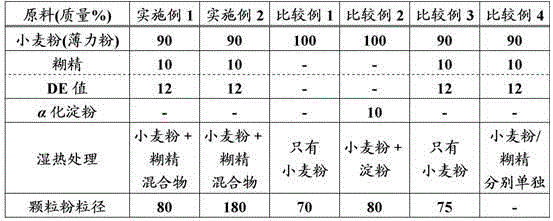

Embodiment 1~2

[0042] The raw materials containing wheat flour (thin flour) and dextrin (DE value: 12) shown in Table 1 were charged into the device described in JP-A-2009-34038, and 10% of the total amount of wheat flour and dextrin was added water, and then perform a moist heat treatment for 5 seconds under the conditions of a gauge pressure of 25 kPa and a temperature of 105°C. Drying and cooling after wet heat treatment, passing through a 26 mesh or 30 mesh sieve to prepare an average particle size of 80 mu m (Example 1) and 180 mu The granular powder of m (embodiment 2).

Embodiment 3~5

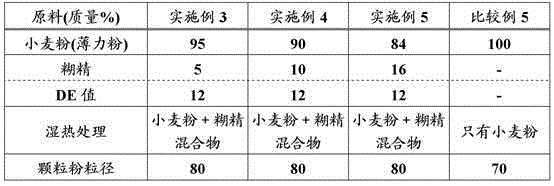

[0066] According to the same steps as in Example 1, the raw materials containing wheat flour (thin flour) and dextrin (DE value: 12) shown in Table 6 are used to prepare granular powder (average particle diameter is 80 mu m).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com