Cutting device

A cutting device and cutting fluid technology, which is applied to fine working devices, working accessories, stone processing equipment, etc., can solve the problem of difficulty in completely preventing chip adhesion, and achieve the effect of preventing tightening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

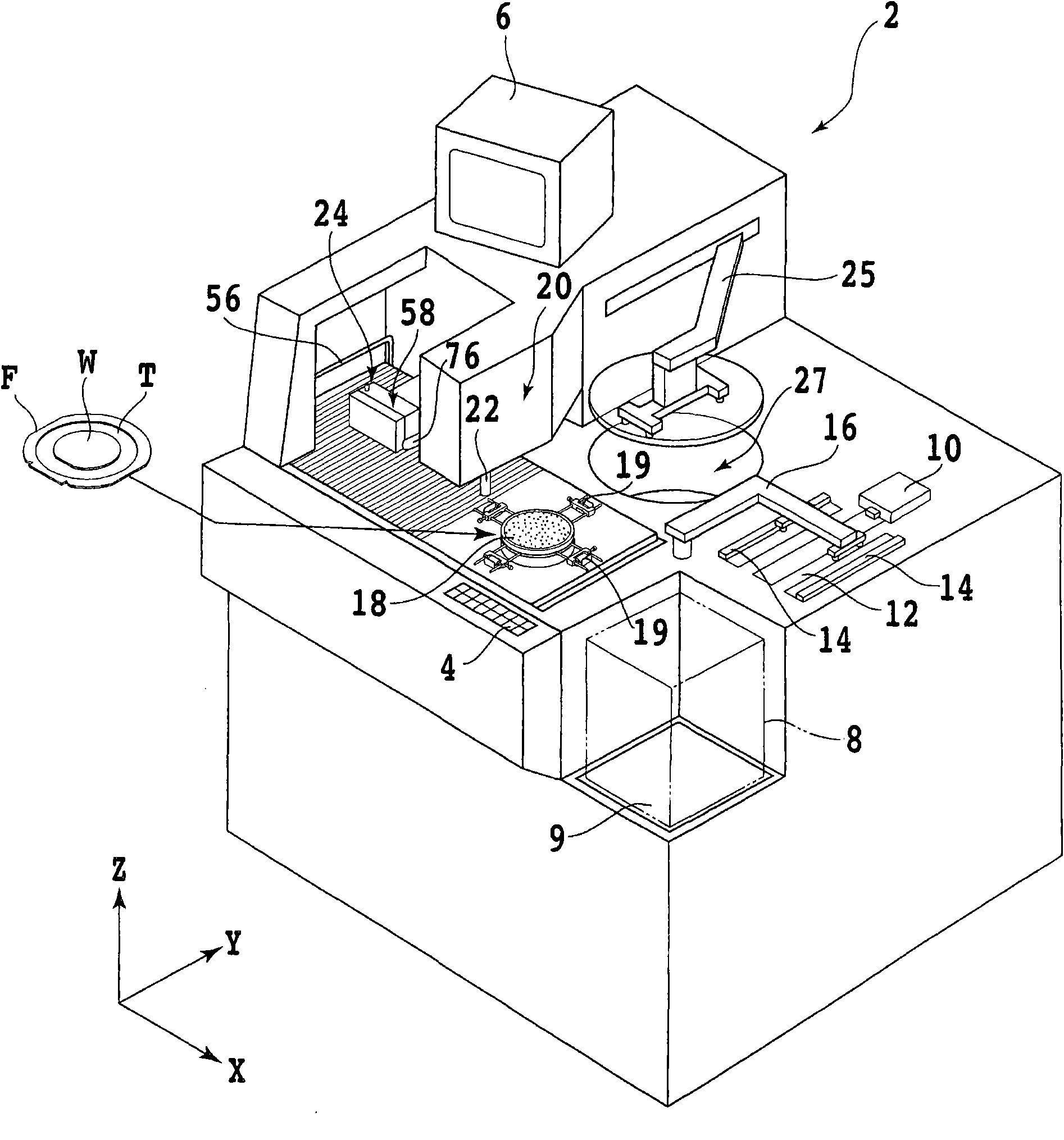

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 The appearance of the cutting device 2 according to the first embodiment of the present invention is shown. On the front side of the cutting device 2 is provided an operating member 4 for an operator to input instructions to the device such as machining conditions. A display unit 6 such as a CRT (Cathode Ray Tube: Cathode Ray Tube) for displaying a guidance screen for an operator or an image captured by an imaging unit described later is provided on the upper part of the device.

[0024] Reference numeral 8 denotes a wafer cassette, and a plurality of (for example, 25) semiconductor wafers supported by a ring frame via dicing tapes are accommodated in the wafer cassette 8 . The wafer cassette 8 is placed on a cassette elevator 9 capable of moving up and down.

[0025] Arranged behind the wafer cassette 8 is an unloading and loading member 10 that unlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com