Scale removing method and scale removing device

An oxide scale and steel pipe technology, applied in the field of oxide scale removal devices, can solve problems such as poor suction ability of vacuum cleaners, and achieve the effect of improving the working environment and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

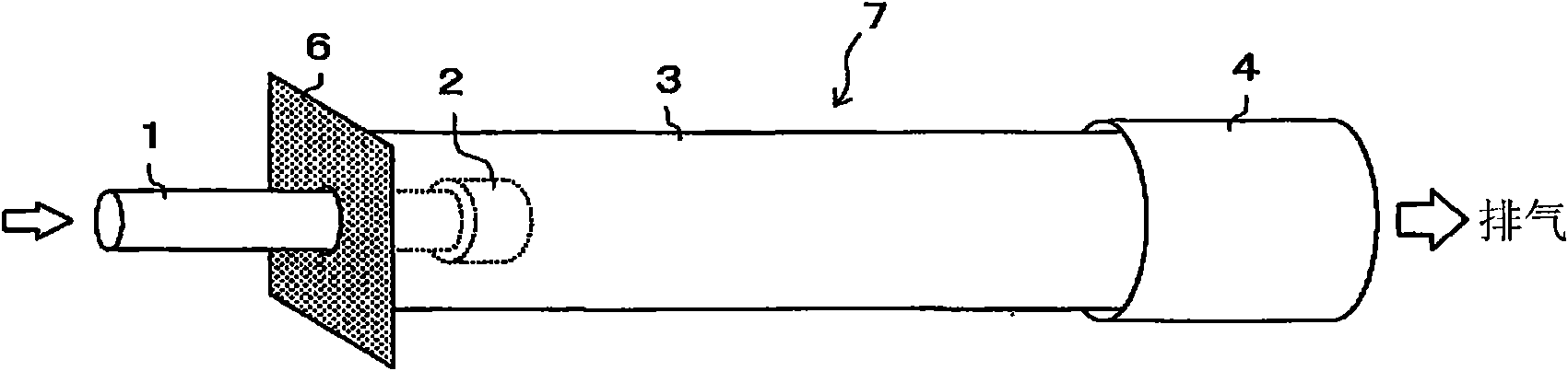

Embodiment 1

[0040] In order to confirm the effect of the present invention, at first, the following experiment was carried out, that is, a high-pressure injection nozzle was inserted from one end of a pipe with a different inner diameter, and the ejection pressure (nozzle pressure) of the nozzle was changed to make air eject in various ways, and it was confirmed that it was consistent with Air flow at the end of the tube inserted on the opposite side of the end with the nozzle. In the experiment, it is measured that the inner diameter of the abrasive purge material delivery pipe is 5.27mm, and the nozzle pressure is 4.9-39.2N / cm with a high-pressure jet nozzle. 2 The amount of air discharged from the end of the pipe when the air is injected into the steel pipe with different inner diameters. The result is expressed in Figure 5 .

[0041] If the air flow in the pipe is 2Nm 3 Below 14.0kW (caliber 100Φmm, 1750rpm, -5000mmAq) low-capacity blower can completely remove the dust generated d...

Embodiment 2

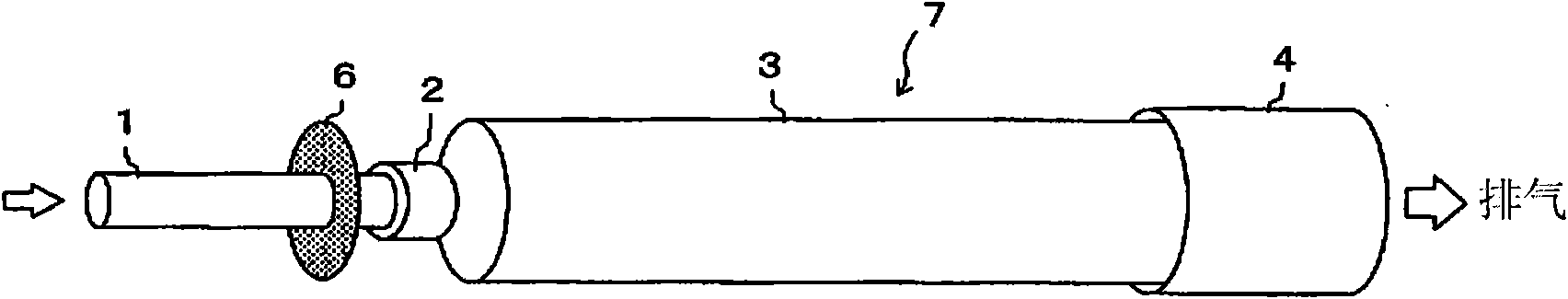

[0044] Next, use figure 1 The suppressing member of the present invention shown was subjected to an experiment in which a high-pressure injection nozzle was inserted into one end of a pipe having various pipe inner diameters, and the pressure of the nozzle was ejected while the end of the pipe on which the nozzle was inserted was blocked. 39.2N / cm 2 As above, check the air flow rate at the pipe end opposite to the pipe end where the nozzle is inserted. The result is expressed in Figure 6 . in addition, Figure 6 The comparative example in is the above-mentioned 39.2N / cm 2 example of.

[0045] Such as Figure 6 Shown, in the example of the present invention, even in the spray 39.2N / cm 2 In the case of such a high pressure air, the air flow in the pipe will not increase that much, and in any case, the air flow in the pipe can be limited to 5Nm 3 / min or less.

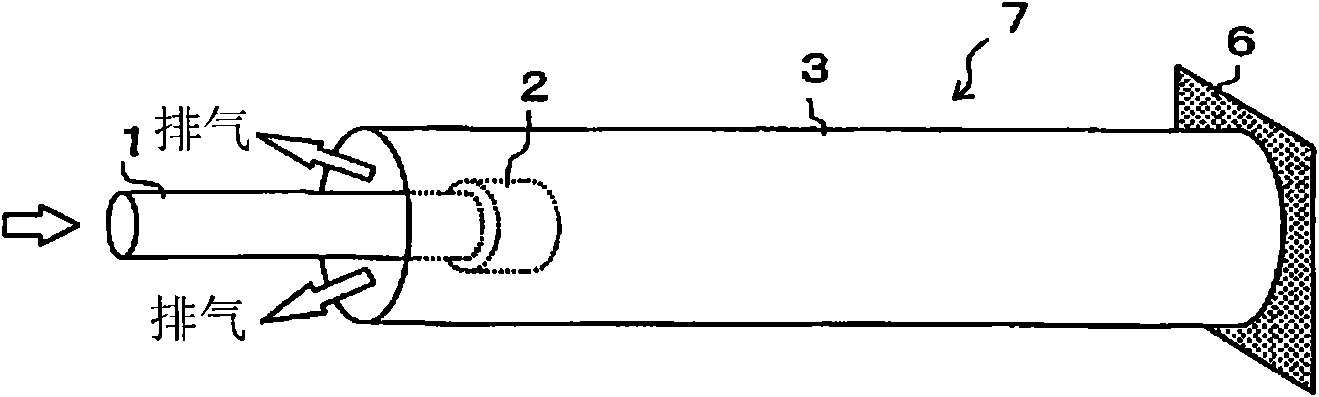

[0046] Next, use figure 2 and image 3 The suppression components shown were subjected to the same experi...

Embodiment 3

[0048] Next, in order to study the conditions under which no dust is generated, steel pipes with outer diameters of 88.9mm, 114.3mm and 177.8mm were prepared, and a high-pressure jet nozzle (nozzle diameter: 10.0mm) was inserted from one end of the steel pipe, while jetting and grinding purge material (jet flow rate: 5.9Nm 3 / min), while using the vacuum cleaner connected to the other end to inhale the jet grinding purge material (suction flow: 11.9Nm 3 / min), the generation of dust and the flow rate in the pipe at this time were investigated. Suction flow rate / jet flow rate (hereinafter referred to as “Yc”) is 2. Such as Figure 7 As shown, experiments were carried out in which a suppressing plate having a size equal to or greater than the inner diameter of the steel pipe was prepared as a suppressing member near the pipe end on the nozzle insertion side, and the distance a between the pipe end and the suppressing plate was varied in various ways. The flow rate in the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com