Thermal-release adhesive tape and cutting method of electronic component

A thermal peeling and adhesive tape technology, applied in the direction of adhesive types, ester copolymer adhesives, polymer adhesive additives, etc., can solve the problem of no chip retention characteristics become good, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

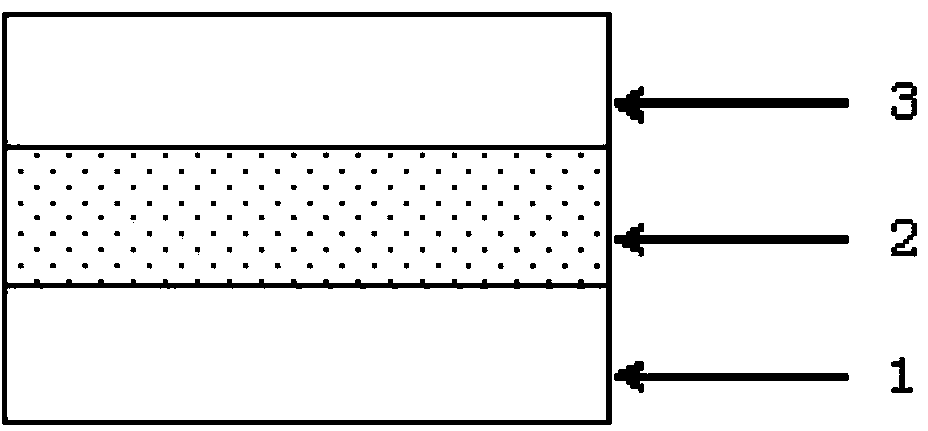

[0162] Made in 100 parts by weight of acrylic copolymer (ethyl acrylate: 2-ethylhexyl acrylate: hydroxyethyl acrylate: methyl methacrylate = 70 parts by weight: 30 parts by weight: 5 parts by weight: 6 parts by weight) Mix 2 parts by weight of an isocyanate crosslinking agent (CORONATE L manufactured by Nippon Polyurethane Industry Co., Ltd.) and add toluene to uniformly mix the resulting solution, and apply it on a PET substrate with a thickness of 100 μm to a thickness of 10 μm after drying. (rubber-like organic elastic layer).

[0163] In addition, 2 parts by weight of an isocyanate crosslinking agent, terpene phenolic tackifier resin (YS Polystar S145 manufactured by Yasuhara Chemical Co., Ltd., hydroxyl value 100 mgKOH / g , acid value 2mgKOH / g) 30 parts by weight, and thermally expandable microspheres (Matsumoto Microsphere F-50 manufactured by Matsumoto Yushi Pharmaceutical Co., Ltd.) 35 parts by weight of the toluene solution, which is coated on the PET substrate separat...

Embodiment 2

[0166] 100 parts by weight of the above-mentioned acrylic copolymer were mixed with 2 parts by weight of an isocyanate crosslinking agent (CORONATE L manufactured by Nippon Polyurethane Industry Co., Ltd.), a terpene phenolic tackifier resin (TAMANOL 901 manufactured by Arakawa Chemical Co., Ltd., Hydroxyl value 45mgKOH / g, acid value 52mgKOH / g) 30 parts by weight, and heat-expandable microspheres (Matsumoto Microsphere F-50 manufactured by Matsumoto Yushi Pharmaceutical Co., Ltd.) 35 parts by weight of toluene solution, which is coated on PET On the substrate separator (38 μm), the thickness after drying was 35 μm (heat-expandable adhesive layer 2). Except having used the heat-expandable pressure-sensitive adhesive layer 2, the heat-peelable pressure-sensitive adhesive sheet 2 was obtained by the method similar to Example 1.

Embodiment 3

[0168]2 parts by weight of an isocyanate crosslinking agent (CORONATE L manufactured by Nippon Polyurethane Industry Co., Ltd.), rosin phenolic tackifier resin (SUMILITE manufactured by SUMITOMO BAKELITE CO., LTD.) were prepared by mixing 100 parts by weight of the above-mentioned acrylic copolymer. RESIN PR-12603, acid value 65mgKOH / g) 30 parts by weight, and heat-expandable microspheres (Matsumoto Microsphere F-50 manufactured by Matsumoto Yushi Pharmaceutical Co., Ltd.) 35 parts by weight of toluene solution, which was coated on the PET substrate On a material separator (38 μm), the thickness after drying was 35 μm (thermally expandable adhesive layer 3). A heat-peelable pressure-sensitive adhesive sheet 3 was obtained in the same manner as in Example 1 except that the heat-expandable pressure-sensitive adhesive layer 3 was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com