Full-plastic joint connecting device for steel wire skeleton plastic composite pipes and construction method

A technology for connecting joints and steel mesh, which is applied in the direction of pipeline connection layout, pipe/pipe joints/pipe fittings, pipes, etc., which can solve the working environment that cannot effectively meet the sub-high pressure, the influence of the overall structural strength of standard parts, and the compression resistance of connecting parts. Ability to decline and other problems, to solve the problem of anti-corrosion, improve connection safety, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

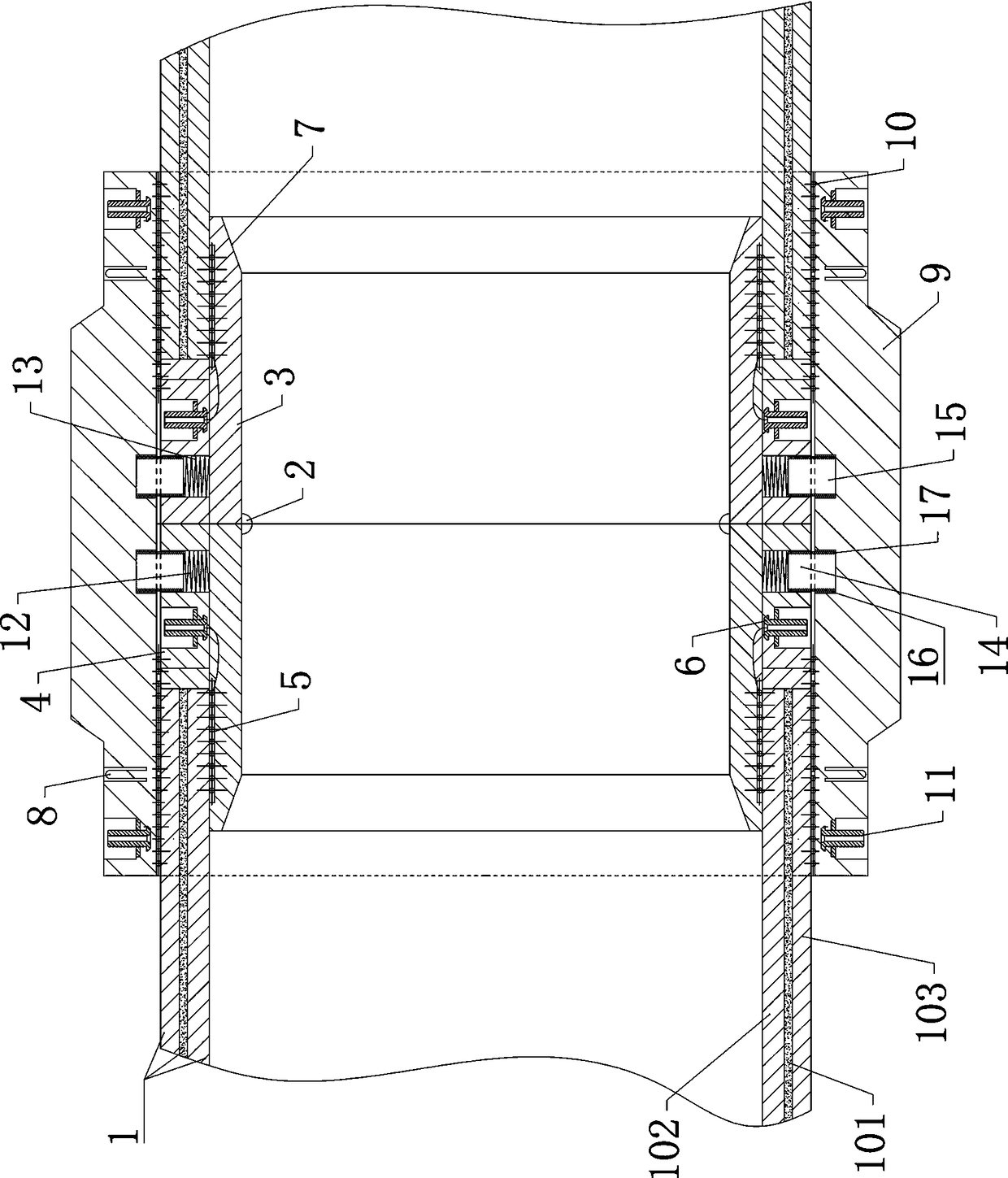

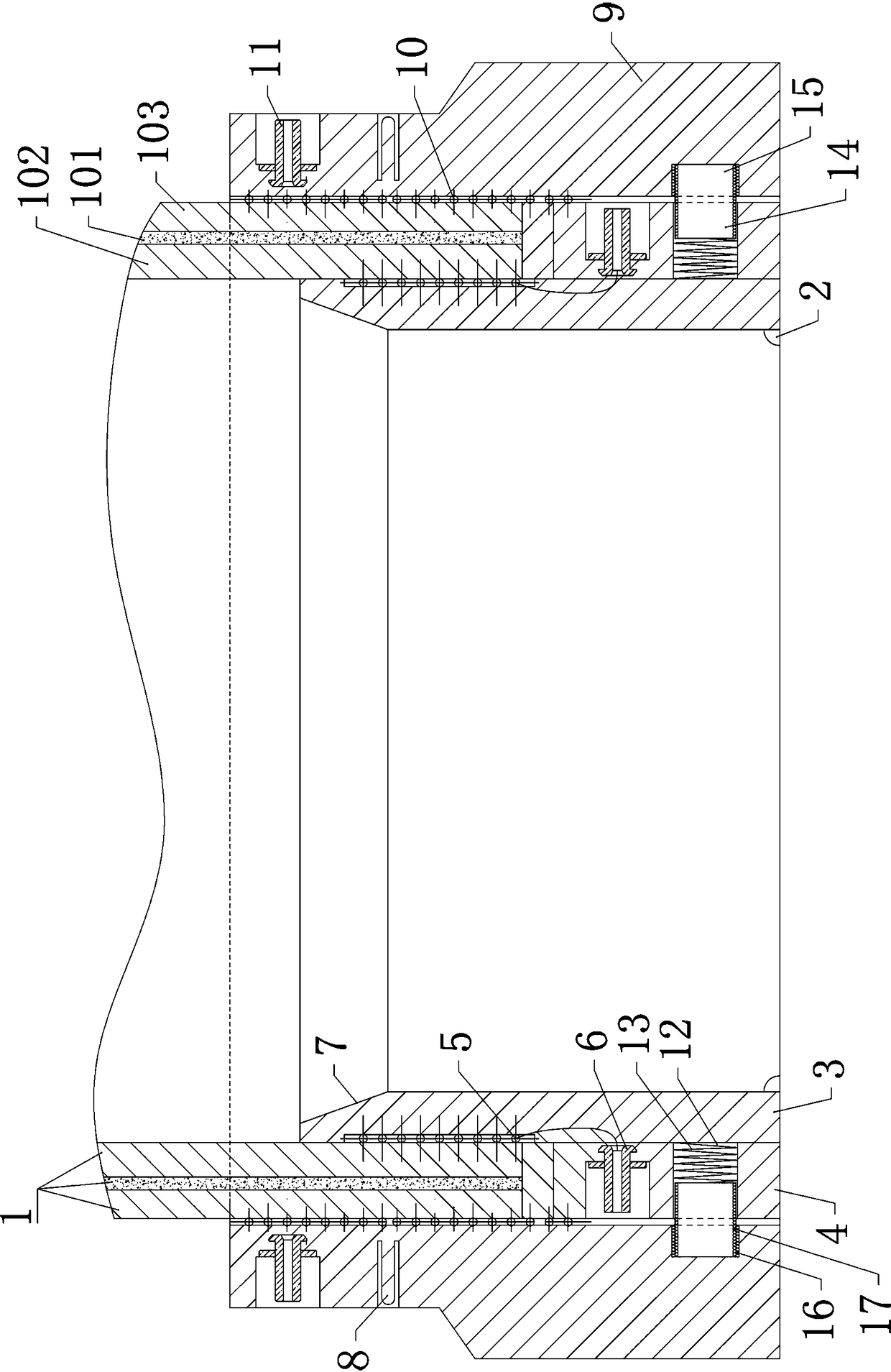

[0026] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0027] Such as Figure 1-2 As shown in , the all-plastic connection joint device of the steel wire frame plastic composite pipe includes two oppositely arranged steel wire frame plastic composite pipes 1, and an inner layer connector is arranged in the middle of the two steel wire frame plastic composite pipes 1; The outer sidewalls on both sides of the layer connector are hot-melt connected with the inner wall of the steel mesh skeleton plastic composite pipe 1 at the corresponding position, and an outer layer connector is sleeved on the outer side of the inner layer connector, and the two outer layer connectors The inner walls of one side are hot-melt connected with the outer side walls of the steel mesh skeleton plastic composite pipe 1 on the correspo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com