Pipe fitting and hose

A technology of pipe joints and shapes, applied in the field of hoses, which can solve the problems of the overall length of the pipe joint 100 becoming longer, the number of parts increasing, and the outer diameter of the pipe joint becoming larger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Embodiments of the present invention will be described below with reference to the drawings.

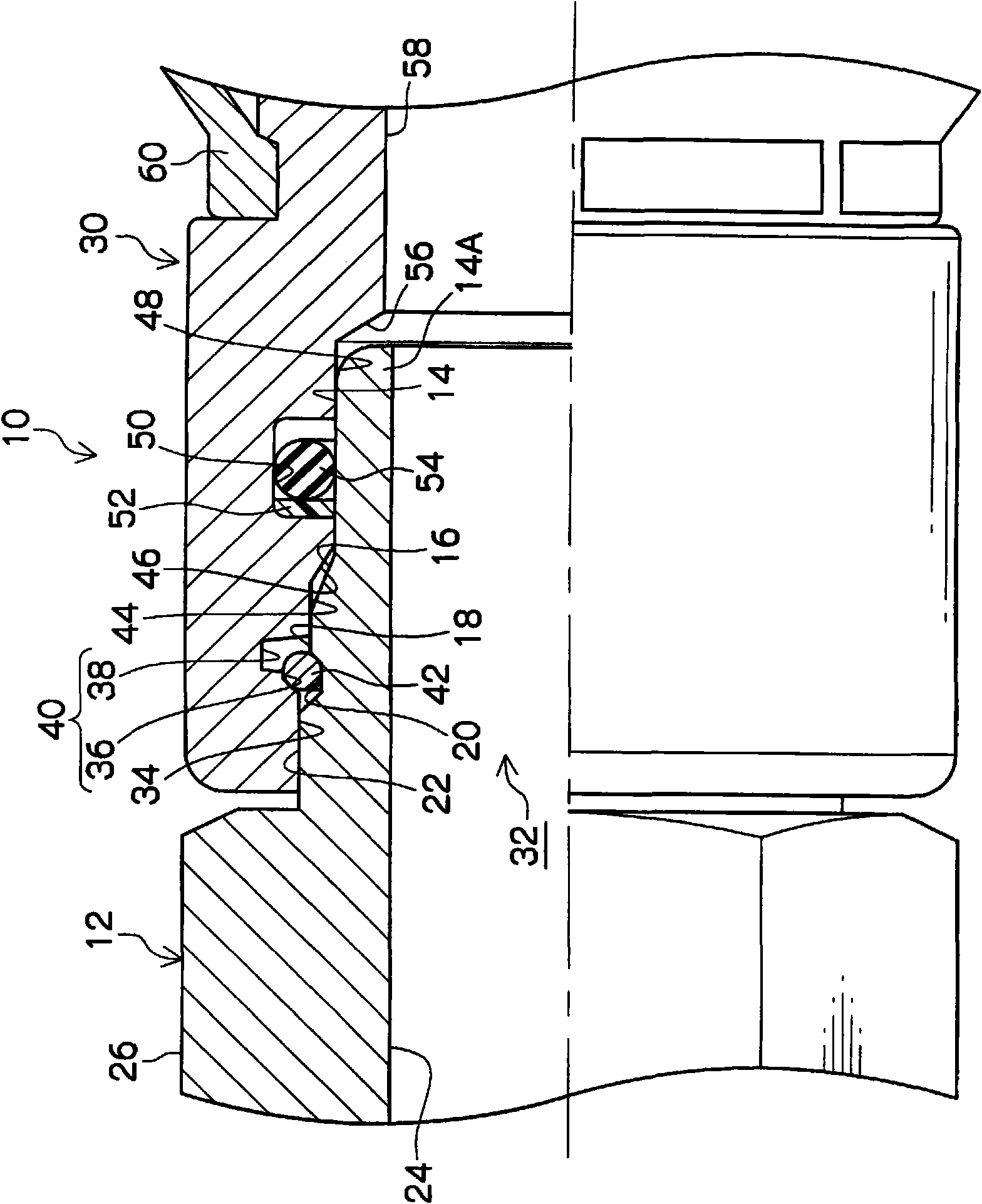

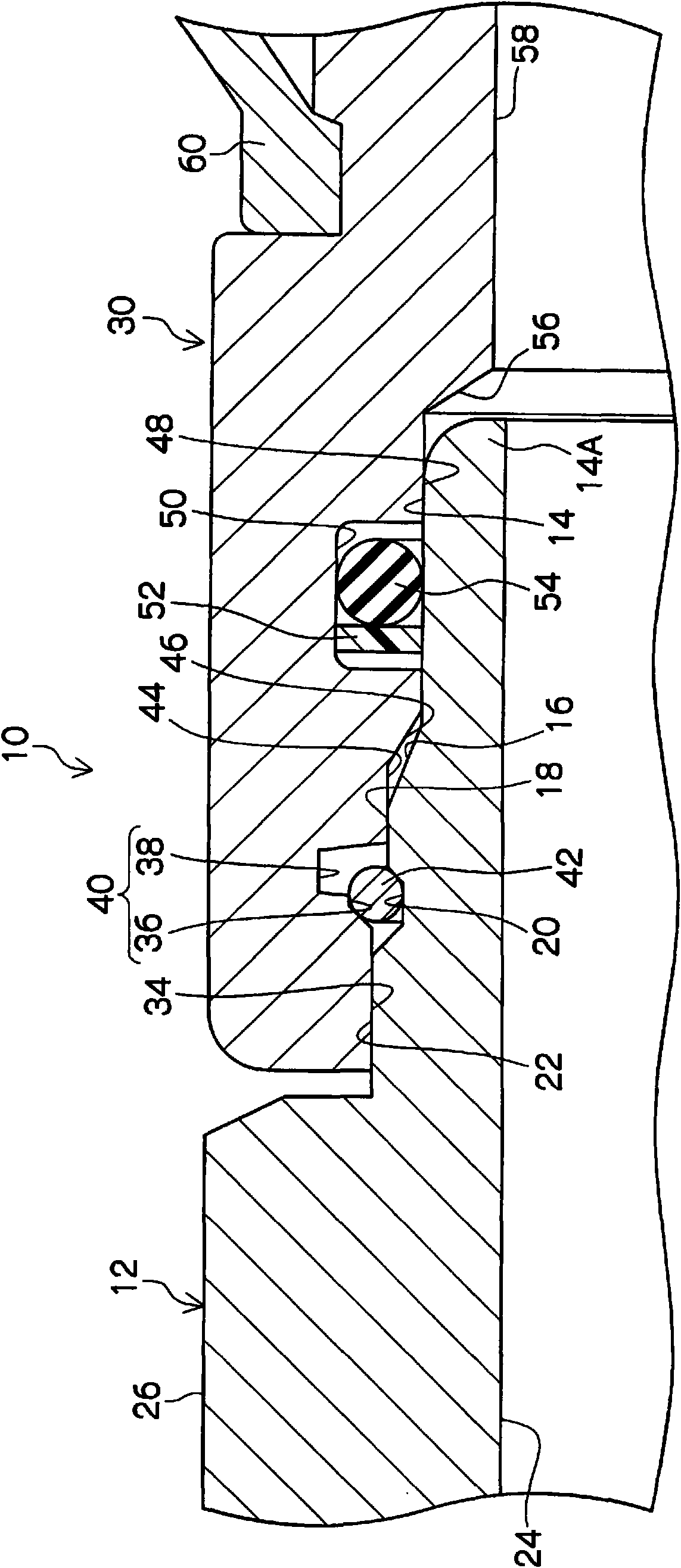

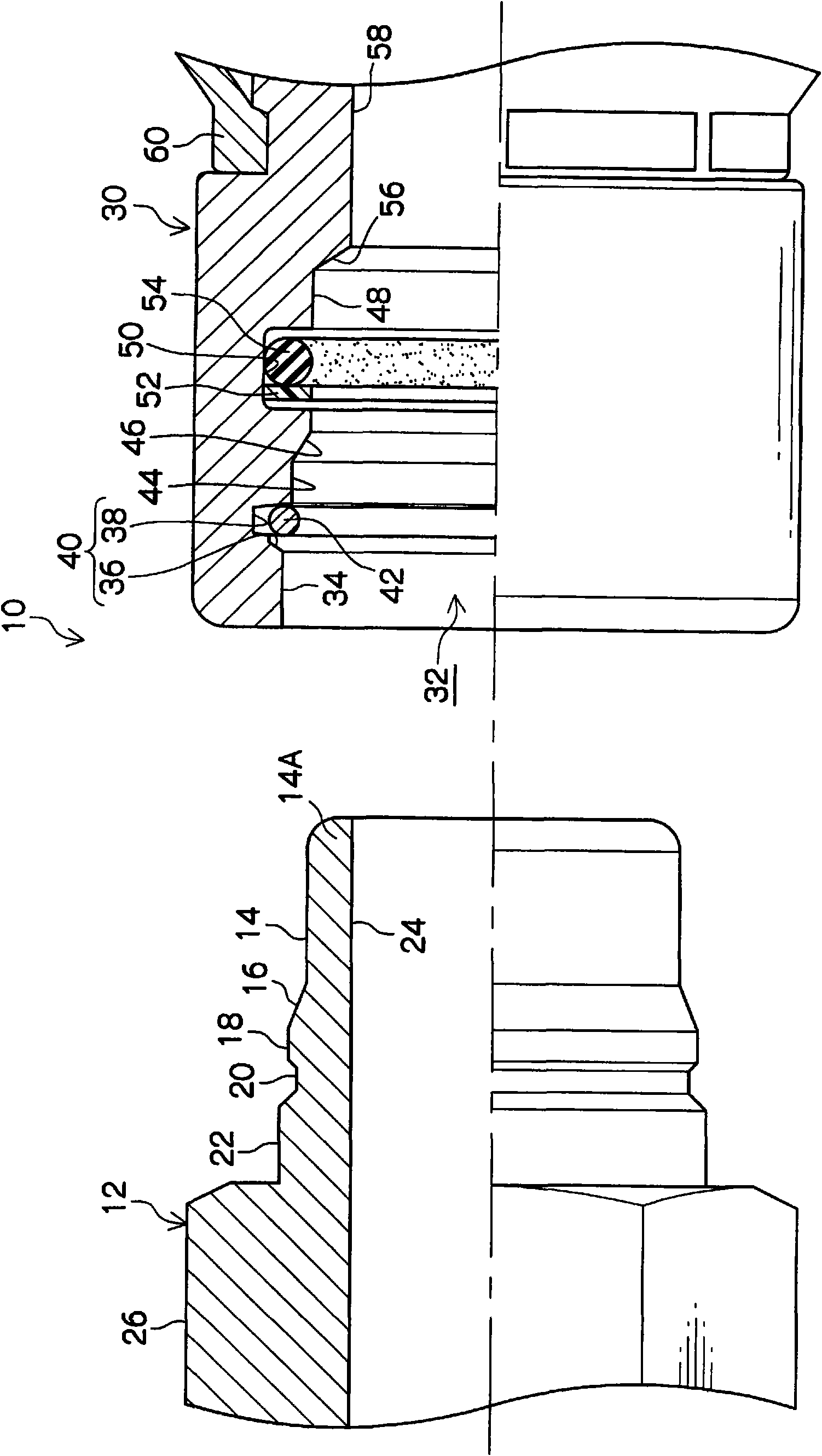

[0076] figure 1 It is a half-broken sectional view showing the coupling state of the pipe joint 10 according to the first embodiment of the present invention, figure 2 is a partially enlarged view of the pipe joint 10 . in addition, image 3 It is a half-broken sectional view showing the separated state of the pipe joint 10 .

[0077] The pipe joint 10 is composed of a cylindrical male body 12 and a cylindrical female body 30 into which the male body 12 is inserted. Such as figure 1 and image 3 As shown, the front end side in the length direction of the convex body 12 is a small diameter, and includes in sequence from the front end toward the root: a third cylindrical portion 14; The outer tapered portion 16 of the cylindrical portion 14 is inclined outward; and the second cylindrical portion 18 having an outer diameter larger than that of the third cylindrical porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com